Stainless steel strip, also called stainless steel strip coil and strip stainless steel.

If you are the beginner of this area, you will be an expert through this guide.

The proportion of the nickel and chromium added is different, and the mechanical properties and application fields of the stainless steel strip produced are different.

It is mainly manifested in the following 12 aspects.

12 Factors Related Stainless Steel Strip Selection

Standard

What are stainless steel strips standards?

The stainless steels strip can be of the GB, ASTM, JIS, GOST, and DIN standard types, etc.

Usually the ASTM A 240 is the common standard in global market. If you come from Japan, you should consider to JIS standard to order your strips cargo.

Here below are the stainless steel standards from different countries.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| More Information: Please view worldstainless.org | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Grade

Common use stainless steel strips grades are often represented by digital symbols.

There are 200 series, 300 series, and 400 series.

- 200 Series: Chromium-nickel-manganese austenitic stainless steel

- 300 Series: Chromium-nickel austenitic stainless steel

- 400 Series: Ferritic and martensitic stainless steel

They are expressed in the United States standard, such as 201, 202, 304, 316, 410, 420, 430, etc.

Chinese stainless steel grades are It is indicated by element symbols plus numbers, such as 1Cr18Ni9Ti, 0Cr18Ni9, 00Cr19Ni10, 1Cr17, 3Cr13, 1Cr17Ni7, etc.

Before sending us the inquiry of stainless steel strips, you should indicate the detailed grade of them.

Application

Stainless steel strips have excellent strength, precision surface finish, and are widely used in many industries such as aerospace, petrochemicals, automobiles, textiles, electronics, home appliances, computers, and precision parts processing.

When customers need stainless steel strip for welded pipe production, we will help display our case study for reference.

And our staff work for many applications with rich experience.

Thickness

The conventional thickness of cold rolled stainless steel strip is between 0.1mm and 3mm, and hot rolled strip thickness will be 3mm to 6mm.

Superb thin stainless steel strip thickness(0.02mm to 0.1mm) can be produced as customers requests.

Width

The conventional width of cold rolled stainless steel strip is between 10mm and 600mm

hot rolled strip width will be 600mm to 2000mm.

Special width(minimum 1.4mm) will be manufactured as customer’s requirements.

Tolerance Of Thickness And Width

Stainless Steel Strips Thickness Tolerance: Normally it would be +/-0.01mm. For precision stainless steel foils applications, it would be +/-0.002mm.

Stainless Steel Strips Width Tolerance: Normally it would be +/-0.10mm. For precision stainless steel strips applications, it would be +/-0.02mm.

You can check our below excel list for reference.

| Thickness(mm) | Width<125mm | 125mm≤Width<250mm | 250mm≤Width<600mm |

|---|---|---|---|

| ≥0.03-0.10 | ±0.06T | ±0.10T | ±0.10T |

| ≥0.10-0.15 | ±0.01 | ±0.015 | ±0.020 |

| ≥0.15-0.20 | ±0.015 | ±0.020 | ±0.025 |

| ≥0.20-0.25 | ±0.015 | ±0.020 | ±0.025 |

| ≥0.25-0.30 | ±0.018 | ±0.025 | ±0.030 |

| ≥0.30-0.40 | ±0.020 | ±0.025 | ±0.030 |

| ≥0.40-0.50 | ±0.025 | ±0.030 | ±0.040 |

| ≥0.50-0.60 | ±0.030 | ±0.030 | ±0.040 |

| ≥0.60-0.80 | ±0.030 | ±0.040 | ±0.040 |

| ≥0.80-1.00 | ±0.030 | ±0.040 | ±0.050 |

| ≥1.00-1.20 | ±0.040 | ±0.050 | ±0.050 |

| ≥1.20-1.50 | ±0.050 | ±0.060 | ±0.060 |

| ≥1.50-2.00 | ±0.060 | ±0.070 | ±0.070 |

| ≥2.00-2.50 | ±0.070 | ±0.070 | ±0.080 |

| ≥2.50-3.00 | ±0.080 | ±0.080 | ±0.090 |

Coil Inner Diameter

Coil inner diameter can be divided into many types such as 200mm, 300mm, 400mm, 500mm, etc.

According to customer’s plant equipment core diameter, choosing the right coil inner diameter of each stainless steel strip.

Surface Treatment

Through different processing methods of cold rolling and surface reprocessing after cold rolling, the surface finish of stainless steel can have different types.

The surface processing of stainless steel strips have NO.1, 2B, 2D, No. 4, HL, No. 6, No. 8, BA, TR hard, Rerolled bright 2H, polishing bright and other surface finishes, etc.

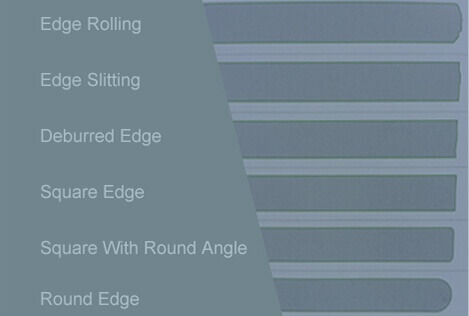

Edge

Rolling Edge

Slit Edge

Deburred Edge

Square Edge

Square With Round Angle Type Edge

Round Edge

Mechanical Properties

The mechanical properties of stainless steels strip includes hardness, YS, TS, elongation, etc.

Many customers are very concerned the hardness when buying stainless steel strip from China market. Hardness is directly related to the chemical composition of the stainless steel. Different states also have a great influence. Our hardness range is from 150HV to 600HV.

The surface processing of stainless steel strips have NO.1, 2B, 2D, No. 4, HL, No. 6, No. 8, BA, TR hard, Rerolled bright 2H, polishing bright and other surface finishes, etc.

| Grade | Standard | Yield Strength Rp0.2 (N/mm²) | Tensile Strength Rm (N/mm²) | Elongation % | Hardness (HV) | Hardness (HRB) |

|---|---|---|---|---|---|---|

| 201 | ASTM A240 | ≥ 275 | ≥ 520 | ≥ 35 | ≤ 260 | ≤ 101 |

| 202 | ASTM A240 | ≥ 275 | ≥ 520 | ≥ 40 | ≤ 218 | ≤ 95 |

| 301 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 304 | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 210 | ≤ 92 |

| 304L | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 316L | ASTM A240 | ≥ 177 | ≥ 480 | ≥ 40 | ≤ 200 | ≤ 90 |

| 316Ti | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 317L | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 218 | ≤ 95 |

| 309S | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 218 | ≤ 95 |

| 310S | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 321 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 347 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 35 | ≤ 200 | ≤ 90 |

| 410S | ASTM A240 | ≥ 205 | ≥ 440 | ≥ 20 | ≤ 210 | ≤ 92 |

| 420J2 | ASTM A240 | ≥ 225 | ≥ 540 | ≥ 18 | ≤ 180 | ≤ 80 |

| 430 | ASTM A240 | ≥ 206 | ≥ 450 | ≥ 22 | ≤ 200 | ≤ 88 |

| 2205 | ASTM A240 | ≥ 450 | ≥ 620 | ≥ 25 | ≤ 293 | ≤ 30 |

| 2507 | ASTM A240 | ≥ 450 | ≥ 620 | ≥ 25 | ≤ 290 | ≤ 30 |

| 253 MA® | ASTM | ≥ 310 | ≥ 600 | ≥ 40 | ≤ 217 | ≤ 95 |

| 254 SMO® | ASTM | ≥ 300 | ≥ 650 | ≥ 35 | ≤ 223 | ≤ 96 |

| 654 SMO® | ASTM | ≥ 430 | ≥ 750 | ≥ 40 | ≤ 250 | ≤ 100 |

| 904L | ASTM | ≥ 216 | ≥ 490 | ≥ 35 | - | ≤ 90 |

| UNS N08926 | ASTM | ≥ 295 | ≥ 650 | ≥ 35 | - | ≤ 100 |

| UNS S17400 | ASTM | ≥ 725 | ≥ 930 | ≥ 10 | - | - |

Weight

For some shipment case, agent of shipping companies do not allow the more weight cargo loading. So each coil with the packaging all gross weight should not be more than 1500kg.

In other condition, customer’s factory line only slit light weight stainless steel strip. So they hope all coils net weight can not be more 600kg.

When you want to place the order to us, please advise how many tons should be packaged before shipment.

Packaging Type

Standard export wooden pallet or wooden case are workable. Also we can meet special requirements from your requests. Delivering strip in coil, hard paper core inside. Eye to wall and eye to sky are both available.

In addition, clear labels are tagged on the outside of the packages for easy identification of the strip before shipment.

Special packaging methods can be done as your requests.

What We Can Do For Your Stainless Steel Strip Project?

Our ability is supplying high quality stainless steel strip material which allows us to provide our clients they need to create superb stainless steel end products.

HZW is one of the leading stainless steel strips suppliers in China, Experts in manufacturing and exporting precision products with 16 years’ rich experience. Call us any time or email us for more benefits here.

In case you have any question, feel free to contact HZW team. Here HZW will help you in all your solutions of stainless steel strip.