17-7PH Stainless Steel Strip

17-7PH Stainless Steel Strip Grade

Quality Stainless Steel Strip Grade:

17-7PH

631

EN 1.4568

DIN X7CrNiAl17-7

What Are 17-7PH Stainless Steel Strip

17-7 PH stainless steel strip, also called 631 precipitation hardening stainless steel strip.

It is a precipitation hardening stainless steel strip that provides high strength and hardness, excellent fatigue properties, good corrosion resistance, good formability, and minimum distortion upon heat treatment.

The alloy strip provides valuable property combinations particularly well suited for aerospace applications.

This special alloy strip also provides benefits for other applications requiring high strength and good corrosion resistance, as well as excellent properties for flat springs at temperatures up to 600°F (316°C).

According to the processing method, the edge of 17-7 PH stainless steel strip can be produced as slit and round types.

The conventional thickness is between 0.1mm and 3.0mm, and the width is less than 600mm.

Different length can be produced according to your detailed request.

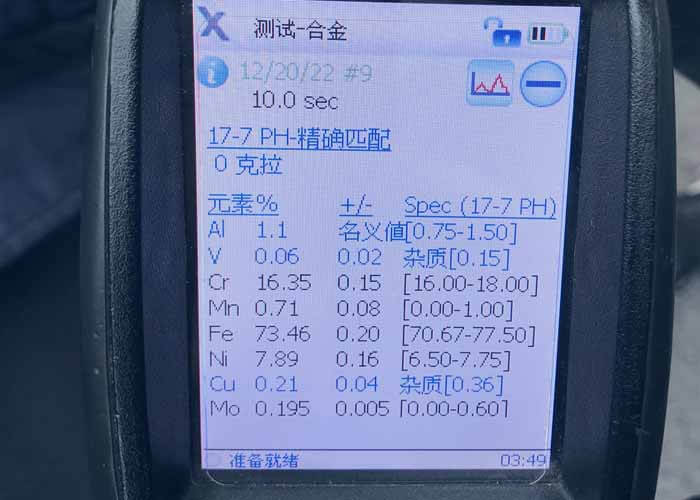

17-7PH Stainless Steel Strip Chemical Components ( % )

- Carbon 0.09 max.

- Manganese 1.00 max.

- Phosphorus 0.040 max.

- Sulfur 0.030 max.

- Silicon 1.00 max.

- Chromium 16.00 – 18.00

- Nickel 6.50 – 7.75

- Aluminum 0.75 – 1.50

17-7PH Stainless Steel Strip Typical Room Temperature Mechanical Properties:

Property | A | T | TH 1050 | A1750 | R100 | RH950 | C | CH900 |

UTS | 896 | 1000 | 1379 | 917 | 1207 | 1620 | 1517 | 1827 |

YS | 276 | 690 | 1276 | 290 | 793 | 1517 | 1310 | 1793 |

Elongation | 35 | 9 | 9 | 19 | 9 | 6 | 5 | 2 |

Hardness, Rockwell | B85 | C31 | C43 | B85 | C36.5 | C48 | C43 | C49 |

We provide 17-7PH cold rolled stainless steel strip as per EN 10151-2003 standard.

What Are 17-7PH Stainless Steel Strips Used For

Due to the high strength and good corrosion resistance, quality grade 17-7PH stainless steel strip is widely used for following applications.

- Retaining rings

- Springs

- Valves and flanges

- Gears

- Aircraft parts

17-7PH Stainless Steel Strips Technical Parameters

Material | 17-7PH Stainless Steel Strip |

Thickness(mm) | 0.1mm-3.0mm |

Width(mm) | Within 600mm |

Length/Roll(meters) | As your request |

Advantages | Grade 17-7PH stainless steel strip provides high strength and hardness, excellent fatigue properties, good corrosion resistance and minimum distortion upon heat treatment. It is easily formed in the annealed condition, then hardened to high strength levels by simple heat treatments to Conditions RH 950 and TH 1050 |

Package | Wooden cases, wooden pallets or as customer’s requests |

Delivery time | Within 20 working days |

MOQ | 2000kgs |

Loading Port | Shanghai port or Ningbo port |

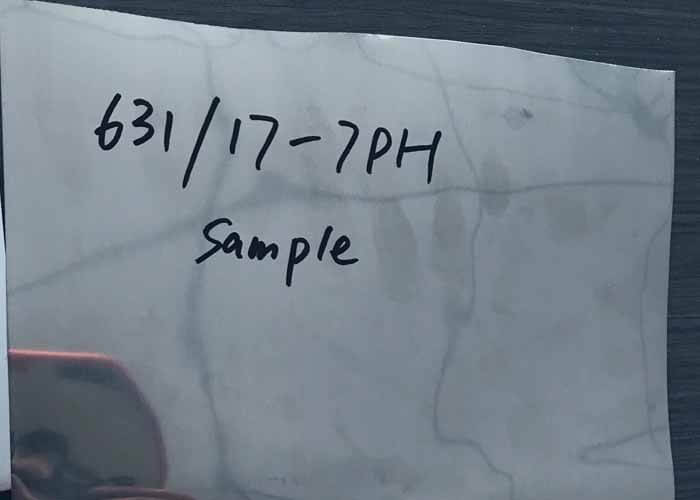

Sample | The sample of 17-7PH stainless steel strip is available |

Equivalent Grades of 17-7PH Stainless Steel Strip

| EU EN | USA – | France AFNOR | England BS | Sweden SS | Russia GOST | Inter ISO |

| X7CrNiAl17-7 | 631 | Z9CNA17-07 | 301S81 | 2388 | 09KH17N7YU | X7CrNiAl17-7 |

What Is 17-7PH Stainless Steel Strip Packaging

HZW has professional packaging team who can adopt developed packaging technology and packaging style to ensure every 17-7PH stainless steel strip packaging quality.

- Standard sea packaging, the stainless steel strip can be done by wooden case and pallet.

- Stainless steel strip surface is protected by waterproof paper and pvc film.

- In addition, clear labels are tagged on the outside of the packages for easy identification of the 17-7PH stainless steel strip measurements and quality information.

How To Buy 17-7PH Stainless Steel Strips

For example, when you want to purchase high quality 17-7PH stainless steel strips products here, the following information should be clarified before placing order:

- Grade: 17-7PH (631, EN 1.4568, DIN X7CrNiAl17-7)

- Application: Sheet Metal Parts

- Standards: ASTM/DIN/EN

- Specifications: Thickness, Width,Tolerance

- Requirement On Properties: Hardness Range, Yield Strength, Tension Strength, Elongation, Round Edge, etc.

- Surface Finish: 2B, Cold Rolled, etc.

- Packaging Requirement: Wooden pallets or wooden cases

- Delivery Time: 15-20 Working days after confirmed the deposit

- Quoted Term: EXW, FCA, FOB, CFR, CIF, DDP, etc