2205 Stainless Steel Strip

2205 Stainless Steel Strip Introductions

What Is 2205 Stainless Steel Strip

2205 stainless steel strip is a duplex stainless steel strip composed of 22% chromium, 2.5% molybdenum and 4.5% nickel-nitrogen alloy.

It has high strength, good impact toughness and good overall and local stress corrosion resistance.

The yield strength of duplex 2205 stainless steel strip is more than twice that of normal austenitic stainless steel strip.

This feature enables engineers and designers to reduce weight when designing related products, making this strip more cost-effective than 316L stainless steel strip and 317L stainless steel strip.

This strip is especially suitable for the temperature range of from -50°F to +600°F.

2205 Stainless Steel Strip Specifications

- Grade: 2205

- Standard: ASTM/EN/JIS

- Thickness: 0.10mm-6.0 mm

- Width: 10mm-1000 mm

- Length: coil type or it can be produced as customer requirements

- Surface Finish: NO.1, 2B, 2H(Rerolled Bright), BA, No.4, 8K (Mirror), HL (Hairline), Polishing Bright, etc

- Edge: Mill Edge, Slit Edge, Deburred Edge, Round Edge, V Type Edge

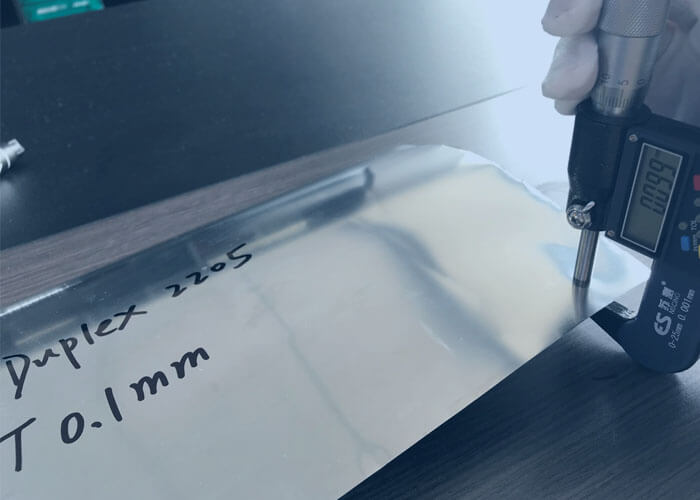

0.1mm Thickness Duplex 2205 Stainless Steel Strip Case Study

Duplex 2205 Stainless Steel Strip 0.1mm Thickness Test (0.099mm)

2205 Stainless Steel Strip Applications

Due to the super strength and excellent corrosion resistance features, quality grade 2205 stainless steel strip is widely used for below applications.

- Pressure vessels, high pressure storage tanks, high pressure pipelines

- Heat exchangers fittings, chemical processing industry

- Oil and gas pipelines,

- Sewage treatment system

- Pulp and paper industry classifiers, bleaching equipment, storage and processing systems

- High speed blades, impellers

- Cargo box of ship and truck

- Food processing equipment

2205 Stainless Steel Strip Chemical Composition

The chemical components of grade 2205 stainless steel strip is summarized in the following table:

| Grade | Standard | C | Si | Mn | P | S | Cr | Ni | Mo |

| 2205 | ASTM A240 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.040 | ≤0.030 | 21.00-24.00 | 4.50-6.50 | 2.5-3.5 |

2205 Stainless Steel Mother Coil Mechanical Property

Below The Table Is For Your Reference:

| Grade | Standard | Yield Strength Rp0.2 (N/mm²) | Tensile Strength Rm (N/mm²) | Elongation % | Hardness (HV) | Hardness (HRB) |

|---|---|---|---|---|---|---|

| 201 | ASTM A240 | ≥ 275 | ≥ 520 | ≥ 35 | ≤ 260 | ≤ 101 |

| 202 | ASTM A240 | ≥ 275 | ≥ 520 | ≥ 40 | ≤ 218 | ≤ 95 |

| 301 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 304 | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 210 | ≤ 92 |

| 304L | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 316L | ASTM A240 | ≥ 177 | ≥ 480 | ≥ 40 | ≤ 200 | ≤ 90 |

| 316Ti | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 317L | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 218 | ≤ 95 |

| 309S | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 218 | ≤ 95 |

| 310S | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 321 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 347 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 35 | ≤ 200 | ≤ 90 |

| 410S | ASTM A240 | ≥ 205 | ≥ 440 | ≥ 20 | ≤ 210 | ≤ 92 |

| 420J2 | ASTM A240 | ≥ 225 | ≥ 540 | ≥ 18 | ≤ 180 | ≤ 80 |

| 430 | ASTM A240 | ≥ 206 | ≥ 450 | ≥ 22 | ≤ 200 | ≤ 88 |

| 2205 | ASTM A240 | ≥ 450 | ≥ 620 | ≥ 25 | ≤ 293 | ≤ 30 |

| 2507 | ASTM A240 | ≥ 450 | ≥ 620 | ≥ 25 | ≤ 290 | ≤ 30 |

| 253 MA® | ASTM | ≥ 310 | ≥ 600 | ≥ 40 | ≤ 217 | ≤ 95 |

| 254 SMO® | ASTM | ≥ 300 | ≥ 650 | ≥ 35 | ≤ 223 | ≤ 96 |

| 654 SMO® | ASTM | ≥ 430 | ≥ 750 | ≥ 40 | ≤ 250 | ≤ 100 |

| 904L | ASTM | ≥ 216 | ≥ 490 | ≥ 35 | – | ≤ 90 |

| UNS N08926 | ASTM | ≥ 295 | ≥ 650 | ≥ 35 | – | ≤ 100 |

| UNS S17400 | ASTM | ≥ 725 | ≥ 930 | ≥ 10 | – | – |

2205 Stainless Steel Strip Production Tolerance

Below The Table Is For Your Reference:

Thickness Tolerance:

| Thickness(mm) | Width<125mm | 125mm≤Width<250mm | 250mm≤Width<600mm |

|---|---|---|---|

| ≥0.03-0.10 | ±0.06T | ±0.10T | ±0.10T |

| ≥0.10-0.15 | ±0.01 | ±0.015 | ±0.020 |

| ≥0.15-0.20 | ±0.015 | ±0.020 | ±0.025 |

| ≥0.20-0.25 | ±0.015 | ±0.020 | ±0.025 |

| ≥0.25-0.30 | ±0.018 | ±0.025 | ±0.030 |

| ≥0.30-0.40 | ±0.020 | ±0.025 | ±0.030 |

| ≥0.40-0.50 | ±0.025 | ±0.030 | ±0.040 |

| ≥0.50-0.60 | ±0.030 | ±0.030 | ±0.040 |

| ≥0.60-0.80 | ±0.030 | ±0.040 | ±0.040 |

| ≥0.80-1.00 | ±0.030 | ±0.040 | ±0.050 |

| ≥1.00-1.20 | ±0.040 | ±0.050 | ±0.050 |

| ≥1.20-1.50 | ±0.050 | ±0.060 | ±0.060 |

| ≥1.50-2.00 | ±0.060 | ±0.070 | ±0.070 |

| ≥2.00-2.50 | ±0.070 | ±0.070 | ±0.080 |

| ≥2.50-3.00 | ±0.080 | ±0.080 | ±0.090 |

2205 Stainless Steel Strip Packaging

Our company have professional team who can adopt developed packaging technology to assure no any damages of products during transportation.

- Standard export packaging:

Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case; - Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

- Other special packaging will be designed as customer’s request;

- Eye to wall and eye to sky are both available;

- By International Express: DHL/UPS/FEDEX/EMS and our own express line;

- By air or By sea;

- Shipping port: Shanghai, Ningbo or as your request.

What Are The Advantages of Cooperating With Us

Our factory owned advanced processing production lines which can support you 2205 stainless steel strip project with competitive price and good service. We have powerful manufacturing capability, our Twenty-high Roll Sendzimir Mill, Continuous Bright Annealing Oven, Tension Leveller, Slitting Machine Lines, Edge Trimmers and Packaging Lines.

We are able to support every different stainless steel strip regardless of the samples or mass production.

When it comes to 2205 stainless steel strips and foils manufacturing process from mother coils to the end products, here you can find complete solutions. The quality stainless steel strips that we produce are exceptionally flat, super thin, up to 600mm width, and manufactured to the tightest tolerances for end users precision demand usage.

Technical Support

Hard work of our quality control and technical engineers team guaranteed the stable quality and good service.

OEM/ODM Service Is Available

Our professional team are skilled at independent development and design. We are able to design, develop, produce and deliver your order according to your detailed requirements, samples or just an idea.

Flexible Payment Term Support

Sample order is available. For small sample orders, in order to save the bank charge for customers and seller, West Union, Money Gram are well recommended.

For mass production, normally our company need 50% TT deposit before new production, and the 50% TT balance payment before shipment.