UNS C10200 TU1 Oxygen Free Copper Strips For Transformers Winding

Your Premier UNS C10200 TU1 Oxygen Free Copper Strips For Transformers Winding Manufacturer

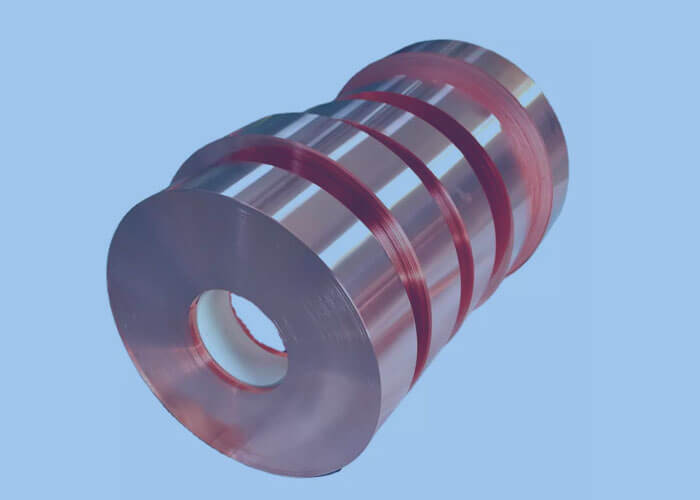

UNS C10200 TU1 Oxygen Free Copper Strips For Transformers Winding

UNS C10200 TU1 oxygen free copper strips for transformers winding is a high purity, oxygen free, non phosphorus-deoxidized copper materials.

It has a very high electrical and thermal conductivity, good welding and excellent soldering properties.

It has excellent hot and cold forming properties, and a good corrosion resistance, especially in atmosphere due to a good adherence of the oxide layer.

1.Quick Details of UNS C10200 TU1 Oxygen Free Copper Strips For Transformers Winding

| Product Name | UNS C10200 TU1 Oxygen Free Copper Strips For Transformers Winding |

| Grades | UNS C10200/GB TU1/JIS C1020 |

| Temper | O |

| Thickness | 0.01mm-3.0mm |

| Width | 5mm-1200mm |

| Edge | Slit/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 150mm,Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on special request |

| Surface Finish | The strip has a smooth surface, free from scratches and impurities |

| Cu (Min) | 99.95% |

Electrical Conductivity (20℃)(IACS) | ≥99.80% |

| Applications | Transformer Winding |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 7-10 working days |

| MOQ | 500Kgs |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of copper foil strip is available |

| Remark | UNS C10200 TU1 copper foil strip can be customized |

2.Technical Specifications

| Technical Specifications | |

| Product Name | UNS C10200 TU1 Oxygen Free Copper Strips For Transformers Winding |

| Thickness 0.01mm – 3.00 mm | |

| Width 5mm – 1200 mm | |

| t<0.01 and t>3.00 on special request | |

| Thickness Core Tube | = minimun 15 mm |

| = maximun 20 mm | |

| Edge Deburring Range | Thickness ≤0.20 mm;Burr≤0.03mm |

| Thickness >0.20mm ;Burr≤0.05mm | |

| Staggered floor | Thickness ≤0.20 mm; Staggered floor≤0.5mm |

| Thickness >0.20mm ; Staggered floor≤2mm | |

| Turriform | Thickness ≤0.20 mm; Turriform≤4mm |

| Thickness >0.20mm ; Turriform≤5mm | |

| Protection | Possibility for paper-interleaving and paper core. |

| Thickness 0.01mm – 3.0 mm | |

| Width 5mm– 1200 mm | |

3.Chemical Composition

| Element | Content (%) |

| Cu | 99.95 |

4.Mechanical Properties of UNS C10200 TU1 Oxygen Free Copper Strips For Transformers Winding

| Property | Units | Temper |

| Annealed* (O soft) | ||

| Tensile Strength (min) | MPa | 215-254 |

| Elongation (min) | % | 35-55 |

| Hardness | HV | 40-65 |

5.Equivalent Alloy Specifications Of UNS C10200 TU1 Oxygen Free Copper Strips For Transformers Winding

Chinese Grade (GB/T) | Abroad Similar Brand | ||||

INTERNATIONAL | USA | JAPAN | UK | GERMANY | |

(ISO) | (ASTM) | (JIS) | (BS) | (DIN) | |

TU1 | Cu-OF | C10200 | C1020 | C103 | CW008A |

How Copper Foils Strips For Transformers Winding Are Made?

Copper foils strips for transformers winding production process is to use the continuous casting and rolling method to produce long copper strips with a thickness of 0.2mm-1.2mm.

The general production process of copper foil strips is:

1.Copper ingot cast into semi-finished product;

2.The semi-finished product is rolled into a finished product;

3.The finished product is annealed, and then annealed, bundled according to specifications, and aged;

4.Use appropriate packaging for storage or transportation.

UNS C10200 TU1 Oxygen Free Copper Strips For Transformers Winding: The Ultimate Guide

Copper strips have been used for electrical applications for more than a hundred years, and the process to make them is relatively straightforward.

This guide will cover what you need to know about choosing the best UNS C10200 TU1 oxygen free copper strips for transformers winding project needs, including:

What are UNS C10200 TU1 oxygen free copper strips?

Why use copper foil strips instead of other conductors?

How are copper foil strips made?

How are copper strips used in transformer winding?

Want more? Let’s keep reading!

What are UNS C10200 TU1 oxygen free copper strips for transformers winding?

The transformer copper foils strips are the most important part of the transformer manufacturing.

It is mainly used to connect with the transformer core and output terminals.

The foil strip made of high-quality oxygen-free copper, which has good conductivity, has small contact resistance and low temperature rise, and can effectively reduce power loss and ensure long-term stable operation of the transformer.

By using high-quality insulated materials such as polyester film, polyesterimide film and polypropylene film, the transformer copper foils strips can be made into a double-sided coated product by vacuum coating technology.

It has good electrical insulation performance and high mechanical strength. It can meet the requirements of winding in transformers under different voltage grades.

Transformer copper foil is the first and important process of transformer manufacturing. It is not only the basic raw material for producing transformer windings, but also an important part to determine its quality.

The size, shape and thickness of the copper foil are directly related to the process properties of the transformer.

The transformer copper foil refers to a kind of special rectangular copper strip with specific width, thickness and length.

The surface of such strip is relatively smooth and flat, and its cross section is usually rectangular or trapezoidal.

The production method of this strip mainly includes cold rolling method, hot rolling method and casting method.

In addition to being used in power transformers, copper foil strips are also used in current transformers, instrument transformers and other products that require precise winding requirements.

What are the advantages of using copper foils strips for transformers?

- High conductivity – With a good electrical conductivity, you can be assured that your transformer will work properly.

- Low thermal resistance – This reduces the chances of a fire because it helps ensure that all parts remain cool during operation.

- Durable – They are made from materials that can withstand high temperatures and stresses, which makes them more durable than other types of foils.

- Cost effective – These types of foils are more affordable than some other options on the market today, which makes them a great option for anyone looking to save money on their project.

How to buy UNS C10200 TU1 oxygen free copper strips for transformers winding?

If you want to buy C10200 copper strips for transformers, you should know, there are many suppliers and manufacturers produce copper foils and supply to many industries like transformer industry.

But in fact, not all the suppliers have the ability to produce good quality products, some of them just choose cheaper materials but with high price which is not a good choice for users.

Here is a quick guide on how to choose a good supplier.

- First, you should ask the manufacturer whether they can do the inspection themselves before delivery. Most of the large manufacturers have their own inspection team, they will strictly inspect all the goods before delivery.

- Second, you should ask if they use 100% pure raw material to produce your goods, because there are some suppliers use recycled raw material or mixed raw material which may cause problem during using.

- Third, it is better to visit their factory by yourself and check the production line and warehouse by yourself. It will be great if you can check their production process and production equipment. Because it is very important for you to know how they control the quality from process till delivery.

What is UNS C10200 TU1 oxygen free copper strips for transformers winding hardness?

The typical Vickers hardness for the strip material must determinate after annealing process (Hardness Vickers Typical: 40-65HV).

What is the packaging standard of copper foils strips for transformers?

Copper strip is the main raw material used to produce transformer winding. The quality of copper foil strips directly affects the reliability of transformer winding.

Small rolls of copper foil strips are generally packaged in moisture-proof paper, large rolls are generally covered with waterproof plastic film or kraft paper, and then packed with wooden frame or steel frame.

Copper foil strips should be stored in a dry and ventilated place. It is strictly forbidden to contact with corrosive gases such as acid and alkali, corrosive liquids and hydrochloric acid, so as not to cause corrosion of copper foil strips. During transportation, it is necessary to use a moisture-proof method to prevent rain from wetting.

Copper foil length of each roll should be same, packaging mark should have clear and complete information.

- Wooden Pallet: Standard export package, no fumigation; Pallet size: 1.1m x 1.1m x 0.8m; Gross weight: 1 Ton; 4 pallets/20′ FCL; 8 pallets/40′ FCL Or as per customer’s requirements.

- Wooden Box: The standard export package with fumigation certificate, it can avoid any potential damage during the transportation.

How to search the hs code of copper foils strips for transformers?

To find out the detailed HS code of related copper strips, you need to determine the specifications and applications of the strips.

The following are the part of copper strips for transformers

HS code:74091190.00