Nickel Alloy 400 Strip

Your Premier Nickel Alloy 400 Strip Manufacturer

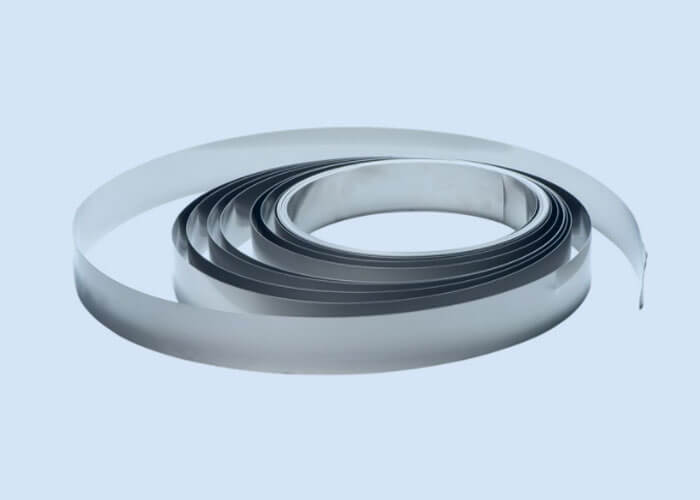

Nickel Alloy 400 Strip

Nickel alloy 400 strip is a Nickel-Copper-based alloy which provides corrosion resistance in a wide range of media, including seawater, hydrofluoric acid, sulfuric acid and alkalies. Nickel alloy 400 strip has excellent tensile and impact strength at high temperatures.

UNS N04400 strip is highly resistant to corrosion in flowing sea-water. The application of Alloy 400 strip is typical for marine, chemical, industrial and consumer applications.

Whatever size at whatever tight tolerance of nickel alloy 400 strips you demand, HZW here is sure to have it!

Specifications of Nickel Alloy 400 Strip

1.Quick Details of Nickel Alloy 400 Strip

| Product Name | Nickel Alloy 400 Strip | UNS N04400 Strip Coil |

| Grades | Alloy 400 |

| Hardness | 60-80HRB |

| Thickness | 0.02mm-3.0mm |

| Width | 1.0mm-600mm |

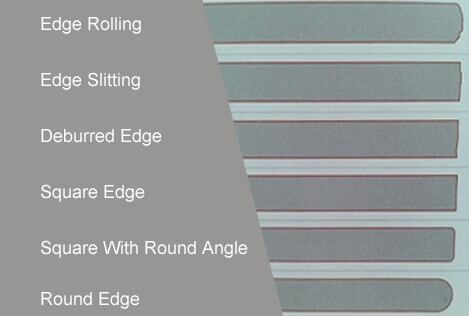

| Edge | Slit/Deburred/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 200mm,Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on customer request |

| Surface Finish | The alloy 400 strip has a smooth surface, free from scratches and impurities |

| Applications | Marine engineering equipment Chemical and hydrocarbon processing equipment Boiler feed water heaters and other heat exchangers Valves, pumps, shafts, fittings, gaskets Industrial heat exchangers Crude oil distillation towers |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 15-20 working days |

| MOQ | 2 Tons |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of nickel alloy 400 strip is available |

| Remark | Nickel alloy 400 strip can be customized |

2.Chemical Composition of Nickel Alloy 400 Strip

Grade | % | Ni | Cu | Fe | C | Mn | Si | S |

Alloy 400/UNS N04400 | Min | Bal | 28 | |||||

Max | 34 | 2.5 | 0.3 | 2 | 0.5 | 0.024 |

3.Mechanical Properties of Nickel Alloy 400 Strip

Grade | TS | YS | EL |

Rm N/mm2 | RP0.2 N/mm2 | A5 % | |

Alloy 400/UNS N04400 | 480 | 170 | 35 |

How is Nickel Alloy 400 Strip Made?

Nickel alloy 400 strip use the cold rolled processing, because of its high nickel content, good corrosion resistance and anti-oxidation ability.

Nickel alloy 400 is also a kind of material with high price, so it is better to use cold rolling processing.

Nickel Alloy 400 Strip Edges Options

Many products managers and engineers have the trouble of nickel alloy 400 strip edges.

In the actual operation process, due to the influence of nickel alloy 400 strip hardness and unloading speed, it is difficult to effectively control the edge of the nickel alloy 400 strip.

However, after our technical personnel have studied for a long time, we have found a solution to this problem. The edge finishing of our strips shall meet the requirements.

Nickel Alloy 400 Strip: The Ultimate Guide

If you are looking to buy nickel alloy 400 strip from China markets, you may want to look at a few things first.

There are many varieties of nickel alloys and blends, each offering their own benefits and drawbacks.

This guide will go into detail about what nickel alloy 400 strip coil is, the different types, and some tips for working with it!

If you are the beginner of this field, here is the right place you go.

What is nickel alloy 400 strip?

The nickel alloy 400 strip, also called UNS N04400 strip.

The nickel alloy 400 strip is a versatile alloy strip that has superb corrosion resistance to a wide variety of corrosive environments.

The alloy is resistant to chloride ion stress-corrosion cracking, to corrosive attack by alkaline solutions and organic and inorganic compounds containing chlorides.

Alloy 400 strip is also resistant to oxidation up to 1200°F but is not recommended for service above 800°F due to loss of ductility resulting from precipitation hardening.

Other typical uses for nickel alloy 400 strip include: salt water pumps, valves and strainers, heat exchangers, and many more.

Features of nickel alloy 400 strip

- Nickel alloy 400 strip has excellent corrosion resistance in the atmosphere, fresh water, sea water, alkaline and acid medium.

- It has good stress corrosion resistance.

- It has good mechanical properties at low temperature.

- It is difficult to be cold deformed, but easy to be hot deformed with 450~500℃ in the heating treatment process.

- Nickel alloy 400 strip can be welded by MIG, TIG, SMAW and submerged arc welding methodss.

Applications of nickel alloy 400 strip

Nickel alloy 400 strip is used in a wide range of applications including:

- Caustic handling equipment

- Condensers and heat exchangers

- High pressure steam lines

- Corrosion resistant valves, pumps and fittings

- Heat treating equipment

What are the advantages of using nickel alloy 400 strip?

Nickel alloy 400 strip is used in different areas of the world due to its higher strength and ductility. It is flexible and can be formed into different shapes.

Here are the advantages of using it:

- It is cost-effective: Nickel alloy 400 strip is cheaper than other nickel based alloys strips. This makes it an option for companies that want to minimize their production costs.

- It is strong and ductile: The strip material has high resistance to corrosion and can be used in corrosive environments.

How to deal with nickel alloy 400 strip packaging?

The packaging for nickel alloy 400 strip is mainly about wooden pallet and wooden box.

The nickel alloy 400 strip length of each roll should be same, packaging mark should have clear and complete information.

- Wooden Pallet: Standard export package, no fumigation; Pallet size: 1.1m x 1.1m x 0.8m; Gross weight: 1 Ton; 4 pallets/20′ FCL; 8 pallets/40′ FCL Or as per customer’s requirements.

- Wooden Box: The standard export package with fumigation certificate, it can avoid any potential damage during the transportation.

How to buy nickel alloy 400 strip from China manufacturers?

To buy nickel alloy 400 strip from China manufacturers, the buyer should consider:

- The China manufacturer’s experience in the metal strips manufacturing industry.

- The quality of goods manufactured by the China manufacturers.

- The financial stability of the manufacturers.

- The supplier’s delivery system.

To get a quick quote for nickel alloy 400 strip you need to know:

- Quantity (Kgs/Tons)

- Size (Thickness x Width x Coil)

- Hardness (65HRB)

- Material Grade (UNS N04400)

- Edge (Slit/Deburred/Round)

- Coil ID (200mm/300mm/400mm/500mm)

- Surface Finish (Smooth)

- Packaging (Eye to eye, eye to wall, wooden pallets, wooden cases)

What is the hs code of nickel alloy 400 strip?

To find out the detailed HS code of related nickel alloy 400 strip, you need to determine the specifications and applications of the alloy 400 strips.

The following are the part of nickel alloy 400 strip:

HS code:75062000.00