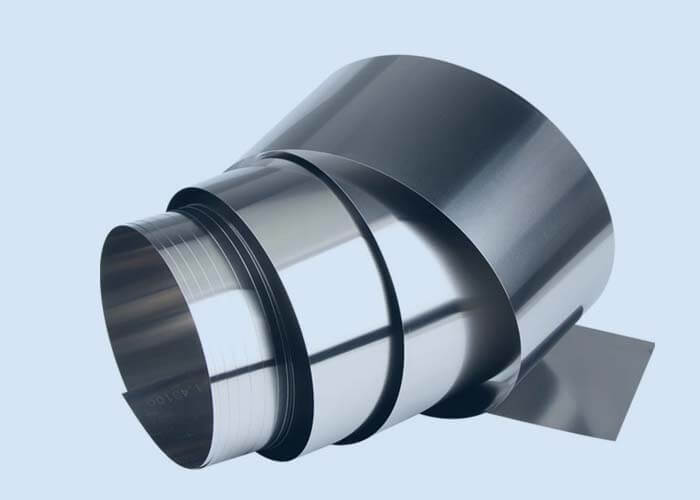

Nickel Alloy 800 Strip

Nickel Alloy 800 Strip

Nickel alloy 800 strip is nickel-iron-chromium superalloy that is part of the family of 800 series of alloy.

Alloy 800 strip exhibits good corrosion resistance in many hostile environments such as high temperature and moderate reducing acids. The high nickel content gives alloy 800 strip its outstanding high temperature properties and resistance to oxidation compared to other nickel alloys strips.

Nickel alloy 800 strip is available in thicknesses ranging from 0.02mm to 3.0mm, in widths up to 600mm and in different hardness depending on the type of material needed for application.

Nickel Alloy 800 Strip Specifications

| Product Name | Nickel Alloy 800 Strip – UNS N08800 Alloy Strip |

| Grades | Alloy 800 |

| Hardness | 126 Brinell or as request |

| Thickness | 0.02mm-3.0mm |

| Width | 1.0mm-600mm |

| Edge | Slit/Deburred/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 200mm,Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on customer request |

| Surface Finish | The alloy 800 strip has a smooth surface, free from scratches and impurities |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 15-20 working days |

| MOQ | 2 Tons |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of nickel alloy 800 strip is available |

| Remark | Nickel alloy 800 strip can be customized |

Nickel Alloy 800 Strip Chemical Compositions

| Nickel 800 Alloy Strip Chemical Composition | |||||||

| % | Ni | Cr | Fe | C | Al | Ti | Al+Ti |

| Alloy 800 | 30-35 | 19-23 | 39.5 min | 0.10 max | 0.15-0.60 | 0.15-0.60 | 0.30-1.20 |

Nickel Alloy 800 Strip Mechanical Properties

| The mechanical properties of Nickel 800 alloy strips are displayed in the following table | ||

| Properties | Metric | Imperial |

| Tensile Strength(annealed) | 600 MPa | 87 ksi |

| Yield Strength(annealed) | 275 MPa | 39.9 ksi |

| Elongation | 45% | 45% |

How Nickel Alloy 800 Strip Is Made?

The production process of nickel alloy 800 strip is as follows:

1. Nickel Alloy 800 coil preparation

2. Nickel Alloy 800 wide coil cold rolling

3. Nickel Alloy 800 coil leveling & straightening

4. Nickel Alloy 800 strip annealing & cleaning

5. Nickel Alloy 800 strip slitting & cutting

5. Nickel Alloy 800 strip packaging & storage

Nickel Alloy 800 Strip: The Ultimate Guide

You’ll find it hard to find a manually written guide on nickel alloy 800 strip anywhere on the internet, so we’ve decided to write this comprehensive guide covering all aspects of nickel alloy 800 strip.

This article provides you with information about nickel alloy 800 strip and also introduces you to some useful data about the material in general. We hope this will help.

Want more? Let’s keep reading!

What is nickel alloy 800 strip?

Nickel alloy 800 strip is a nickel-iron-chromium alloy with good strength and excellent resistance to oxidation and carburization in high temperature atmospheres.

It also displays excellent resistance to stress-corrosion cracking and has good creep-rupture strength.

The alloy is often used in heat treating equipment, radiant tubes, thermowells, retorts, muffles, lead pots, heat exchangers, still tubing and other high temperature applications.

What are the applications of nickel alloy 800 strip?

Alloy 800 strip is a high nickel alloy containing about 20% chromium contents.

The following are the applications of nickel alloy 800 strip:

- Heat exchanger tubing for petrochemical processing.

- Valves and other piping components for sulfuric acid plants.

- Equipment for handling hydrogen chloride, acetic acid and sodium hydroxide.

- Flue gas desulfurization systems (scrubbers).

How to buy nickel alloy 800 strip?

If you want to buy nickel alloy 800 strip for industrial usage, you should know, there are many suppliers and manufacturers produce nickel alloy 800 strip and supply to many industries.

But in fact, not all the suppliers have the ability to produce good quality products, some of them just choose cheaper materials but with high price which is not a good choice for users.

Here is a quick guide on how to choose a good nickel alloy 800 strip supplier.

- First, you should ask the manufacturer whether they can do the inspection themselves before delivery. Most of the large manufacturers have their own inspection team, they will strictly inspect all the goods before delivery.

- Second, you should ask if they use 100% pure raw material to produce your goods, because there are some suppliers use recycled raw material or mixed raw material which may cause problem during using.

- Third, it is better to visit their factory by yourself and check the production line and warehouse by yourself. It will be great if you can check their production process and production equipment. Because it is very important for you to know how they control the quality from process till delivery.

What is the hardness of nickel alloy 800 strip?

The typical hardness for the alloy 800 strip material must determinate after annealing process (126 Brinell).

What is the packaging standard of nickel alloy 800 strip?

- Wooden Pallet: Standard export package, no fumigation; Pallet size: 1.1m x 1.1m x 0.8m; Gross weight: 1 Ton; 4 pallets/20′ FCL; 8 pallets/40′ FCL Or as per customer’s requirements.

- Wooden Box: The standard export package with fumigation certificate, it can avoid any potential damage during the transportation.