Nickel Alloy C276 Strip

Nickel Alloy C276 Strip

Nickel alloy C276 strip is a nickel-molybdenum-chromium alloy strip with tungsten added for enhanced corrosion resistance in severe environments.

It is one of the most corrosion resistant alloys currently available. The high molybdenum content imparts resistance to localized corrosion such as pitting. The low carbon minimizes carbide precipitation during welding to maintain resistance to intergranular attack in heat affected zones of welded joints.

Because of its excellent corrosion resistance, nickel alloy C276 strip is commonly used in the production of chemical process equipment, flue gas desulfurization scrubbers, paper mill equipment, nuclear waste processing systems, pharmaceuticals production equipment and pickling equipment.

Nickel Alloy C276 Strip Specifications

| Product Name | Nickel Alloy C276 Strip | UNS N10276 Strip |

| Grades | Alloy C276 |

| Hardness | 70-90HRB |

| Thickness | 0.02mm-3.0mm |

| Width | 1.0mm-600mm |

| Edge | Slit/Deburred/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 200mm,Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on customer request |

| Surface Finish | The alloy C276 strip has a smooth surface, free from scratches and impurities |

| Applications | Pressure Vessels Reactors Mixers and Agitators Scrubbers Dampers Heat Exchangers Evaporators Solvent Recovery Plants Pumps and Valves |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 15-20 working days |

| MOQ | 2 Tons |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of nickel alloy C276 strip is available |

| Remark | Nickel alloy C276 strip can be customized |

Nickel Alloy C276 Strip Chemical Compositions

| % | Ni | Cr | Mo | W | Co | C | Mn | Si | P | S | Fe | V |

| Min | Balance | 14.5 | 15 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 0 |

| Max | Balance | 16.5 | 17 | 4.5 | 2.5 | 0.01 | 1 | 0.08 | 0.04 | 0.03 | 7 | 0.35 |

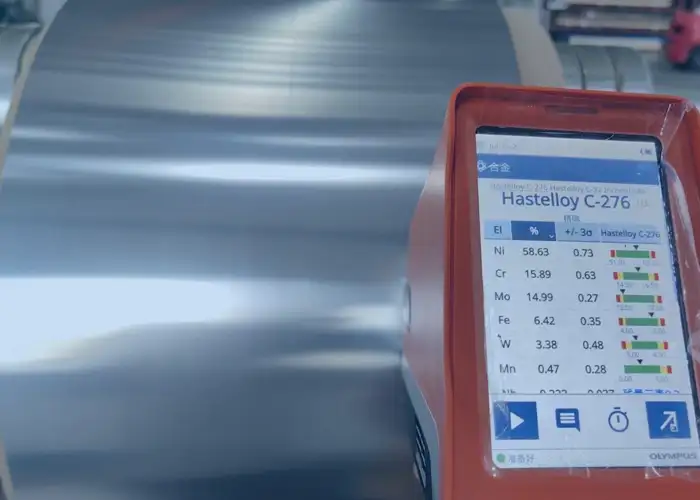

From this picture, you can see how to deal with Hastelloy C-276 alloy foil positive material identification test in our company. The strict control and management to ensure each C-276 alloy foil has right chemical contents.

Nickel Alloy C276 Strip Mechanical Properties

| Element | Yield Strength (0.2%Offset) | Melting Point | Density | Tensile Strength | Elongation |

| Alloy C-276 | Psi – 41,000 , MPa – 283 | 1370 °C (2500 °F) | 8.89 g/cm3 | Psi – 100,000 , MPa – 690 | 40 % |

Nickel Alloy C276 Strip Standards Comparison Table

| STANDARD | Alloy C-276 |

| WERKSTOFF NR. | 2.4819 |

| UNS | N10276 |

How Nickel Alloy C276 Strip Is Made?

The production process of nickel alloy C276 strips is as follows:

1. Nickel Alloy C276 coil preparation

2. Nickel Alloy C276 wide coil cold rolling

3. Nickel Alloy C276 coil leveling & straightening

4. Nickel Alloy C276 strip annealing & cleaning

5. Nickel Alloy C276 strip slitting & cutting

5. Nickel Alloy C276 strip packaging & storage

Nickel Alloy C276 Strip: The Ultimate Guide

Nickel alloy C276 strip is one of the most widely used nickel-based alloys strips in the world.

With its unique characteristics, it has applications across a wide variety of industries.

However, many people may not be aware of all the benefits this particular alloy possesses, so here we will go into some detail about what it is and what makes it so valuable.

Want more? Let’s keep reading!

What is nickel alloy C276 strip?

Nickel alloy C276 strip is a corrosion resistant, nickel-molybdenum-chromium alloy with excellent corrosion resistance in severe environments.

The high molybdenum content makes the alloy especially resistant to pitting and crevice corrosion.

Alloy C276 strip also has excellent resistance to reducing agents like hydrogen chloride gas, and sulfuric, acetic and phosphoric acids. Alloy C276 exhibits excellent resistance to stress-corrosion cracking in boiling 20% to 40% sulfuric acid.

Nickel alloy C276 strip is used in the chemical processing industry, in pollution control equipment and in power generation industries.

The chemical processing industry uses Nickel alloy C276 strip for pumps, valves, heat exchangers, tanks and other components used to process chemicals such as concentrated hydrochloric acid at temperatures up to 150°F (65°C).

Alloy C276 strip is also used for pickling equipment for nitric acid service. This material provides excellent resistance to both oxidizing and reducing acids making it suitable for handling solutions of nitric acid mixed with oxidizing salts such as ferric nitrate or cupric nitrate.

Nickel alloy C276 strip is commonly used for pollution control equipment because of its excellent resistance to atmospheric corrosion.

What are the applications of nickel alloy C276 strip?

Nickel alloy C276 strip is a versatile corrosion resistant material that can be used in many different environments and media.

It is especially resistant to pitting, crevice corrosion and stress corrosion cracking.

Nickel alloy C276 strip is commonly used for the following applications:

- Chemical process industry

- Flue gas desulfurization units

- Pickling equipment in the steel industry

- Waste incineration plants

- Seawater desalination plants

- Flue gas scrubbing facilities

- Pharmaceuticals

- Heat exchangers

What are the advantages of using nickel alloy C276 strip?

The advantages of using nickel alloy C276 strip include:

- High corrosion resistance in a wide range of media. The nickel alloy C276 strip is particularly resistant to stress corrosion cracking and pitting. It is widely used in chemical processing, pollution control, oil and gas recovery, acid production, and pickling operations.

- Excellent resistance in oxidising aqueous media. The nickel alloy C276 strip is often chosen for use in saltwater applications as well as acidic solutions. It is an excellent material for the fabrication of heat exchangers.

- High resistance to intergranular corrosion. Due to its high chromium content, the nickel alloy C276 strip offers good resistance to intergranular corrosion following exposure to temperatures between 425°C and 860°C.

- Good weldability compared to other alloys in the same family. Nickel alloy C276 strip can be welded by most common welding methods. Post weld heat treatment is not required when using this alloys for welding at temperatures below 593°C/1100°F.

How to buy nickel alloy C276 strip?

If you want to buy alloy C276 strip for industrial usage, you should know, there are many suppliers and manufacturers produce alloy C276 strip and supply to many industries like heat exchanger or chemical industry.

But in fact, not all the suppliers have the ability to produce good quality products, some of them just choose cheaper materials but with high price which is not a good choice for users.

Here is a quick guide on how to choose a good alloy C276 strip supplier.

- First, you should ask the manufacturer whether they can do the inspection themselves before delivery. Most of the large manufacturers have their own inspection team, they will strictly inspect all the goods before delivery.

- Second, you should ask if they use 100% pure raw material to produce your goods, because there are some suppliers use recycled raw material or mixed raw material which may cause problem during using.

- Third, it is better to visit their factory by yourself and check the production line and warehouse by yourself. It will be great if you can check their production process and production equipment. Because it is very important for you to know how they control the quality from process till delivery.

What is the hardness of nickel alloy C276 strip?

The typical hardness for the nickel alloy C276 strip material must determinate after annealing process (70-90HRB).

What is the packaging standard of nickel alloy C276 strip?

- Wooden Pallet: Standard export package, no fumigation; Pallet size: 1.1m x 1.1m x 0.8m; Gross weight: 1 Ton; 4 pallets/20′ FCL; 8 pallets/40′ FCL Or as per customer’s requirements.

- Wooden Box: The standard export package with fumigation certificate, it can avoid any potential damage during the transportation.

What is the hs code of nickel alloy C276 strip?

To find out the detailed HS code of related nickel alloy C276 strip, you need to determine the specifications and applications of the alloy strips.

The following are the part of nickel alloy C276 strip.

HS code: 75062000.00