Ao comprar matérias-primas de enrolamento de transformador, você provavelmente encontrará uma grande variedade de tiras de alumínio e tiras de cobre.

Estas são duas das escolhas mais populares de material de enrolamento para transformadores do tipo seco de baixa tensão. A tira de alumínio do transformador e a tira de cobre são semelhantes na aparência. Mas qual é a diferença?

Abaixo de, nós quebramos a história, grau, product type and application of these two very different materials so you can determine which is the best winding strip for your transformer project.

Vamos continuar lendo.

History of Transformer Aluminum Strips

A história de transformer aluminum strips dates back to the early 1900s. This is when electricity was first used to power appliances in homes and businesses, and transformers were used to change electrical voltages.

Aluminum was chosen for its light weight, resistance to corrosion and because it has a high conductivity (the ability to transmit electric current).

The first transformer aluminum strip was made by an American engineer named Charles Proteus Steinmetz (1865-1923). Steinmetz designed his first transformer in 1896 while working for General Electric Company in Schenectady, New York. He invented a way of making aluminum wire that could be wound into coils or flat strips which could then be used as part of an electrical circuit.

Today’s transformers are still made using this same basic principle but they have been refined over time so they can carry more power with less weight and cost to produce. The most common types of transformers are three-phase units that provide alternating current (AC) at various voltage levels depending on the type needed and where it will be used in the electrical system. These include household outlets, industrial facilities and even entire communities like cities or towns.

Grades of Transformer Aluminum Strips

Aluminum strip is a very useful and versatile material for transformers and other electrical equipment. It has many advantages, such as low weight, força elevada, excellent conductivity and corrosion resistance.

The alloys used in the manufacture of aluminum strips are specifically designed for use in transformers.

The grade of an aluminum strip is determined by its chemical composition, mechanical properties and quality control requirements. There are three main grades of aluminum: 1050, 1060, 1070 e 1350.

History of Transformer Copper Strips

Transformer copper strips are made from pure copper and are used in transformers. The material is very strong and flexible, making it ideal for use in electrical equipment. It is also easy to shape, solder and weld.

Although pure copper can be used to make transformer copper strips, this metal is rarely used due to its high cost. Em vez de, a mixture of copper and other metals is often used. This allows the manufacture of a cheaper product that still has the same properties as pure copper.

The first use of transformer copper strips was in 1820 when they were used in the production of telegraphs. These devices had been invented by Samuel Morse and were used to transmit messages over long distances by means of electrical signals sent through wires laid on poles along railway lines or installed underground in cities such as New York City and London, Inglaterra.

Transformer copper strips have been used in many different types of electrical equipment since then including household appliances such as refrigerators and washing machines as well as industrial machines like electric motors and generators that produce power for factories, offices and homes all over the world.

Grades of Transformer Copper Strips

A folha de cobre é um dos principais materiais para a produção de transformadores. Como um importante dispositivo eletrônico, o transformador irá converter uma tensão para outra tensão. As duas bobinas são chamadas de bobina primária e bobina secundária.

As tiras de folhas de cobre do transformador são a parte mais importante da fabricação do transformador.

É usado principalmente para conectar com o núcleo do transformador e os terminais de saída.

A tira de folha feita de cobre livre de oxigênio de alta qualidade, que tem boa condutividade, tem pequena resistência de contato e baixa elevação de temperatura, e pode efetivamente reduzir a perda de energia e garantir a operação estável a longo prazo do transformador.

Copper strips for transformers winding grades are as follows:

- Nota ETP (Passo Eletrolítico Difícil)

- Grau T2

- C11000, C12200, C26000, etc.

What are the Differences Between Transformer Aluminum Strips and Copper Strips?

Como você pode ver em suas notas e padrões,aluminum strip and copper strip is very different. Depending on what you are looking for in your transformer projects, cada um tem vantagens e desvantagens. Para uma comparação lado a lado, você divide as diferenças ainda mais.

Chemical Composition Differences Between Transformer Aluminum Strips and Copper Strips

Aluminum Strips For Transformers Chemical Composition

| 1050 O Composição Química das Tiras de Folhas de Alumínio(%) | |||||||||

| Elemento | Al | E | Fe | Mg | Zn | Mn | Vocês | Com | V |

| Valor padrão | ≥99,5 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

| 1060 O Composição Química das Tiras de Folhas de Alumínio(%) | |||||||||

| Elemento | Al | E | Fe | Mg | Zn | Mn | Vocês | Com | V |

| Valor padrão | ≥99,6 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

| 1070 O Composição Química das Tiras de Folhas de Alumínio(%) | |||||||||

| Elemento | Al | E | Fe | Mg | Zn | Mn | Vocês | Com | V |

| Valor padrão | ≥99,7 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

| 1350 O Composição Química das Tiras de Folhas de Alumínio(%) | |||||||||

| Elemento | Al | E | Fe | Mg | Zn | Mn | Vocês | Com | V |

| Valor padrão | ≥99,5 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

Chemical Composition of Copper Strips For Transformers Winding

| C1100/C11000 Copper Strips Chemical Composition(%) | ||||||||

| Elemento | Cu + Ag | Sn | Zn | Pb | Ni | Fe | Como | O |

| Valor padrão | ≥99,90 | ≤0,002 | ≤0,005 | ≤0,005 | ≤0,005 | ≤0,005 | ≤0,002 | ≤0,06 |

Features Differences Between Transformer Aluminum Strips and Copper Strips

Aluminum strip has several advantages over copper strip. It is more resistant to corrosion and heat, which makes it suitable for outdoor use.

The conductivity of aluminum is lower than that of copper at room temperature but increases as the temperature rises. This means that aluminum is more efficient at transferring heat than copper, making it ideal for electric heating elements and radiators.

Copper can be recycled many times without losing its properties, while aluminum loses its strength after several recycling cycles. Copper can be recycled indefinitely if there is no contamination in the mix; no entanto, pure aluminum cannot be recycled because it corrodes easily when exposed to oxygen or water vapor in the air environment during melting process.

Cost Differences Between Transformer Aluminum Strips and Copper Strips

Aluminum strips are relatively cheaper than copper strips. Contudo, many China suppliers are offering a range of transformer winding materials at competitive prices.

Density Differences Between Transformer Aluminum Strips and Copper Strips

The density of a material is the ratio of its mass to its volume. Density is used as a measure of how compact or voluminous a substance is.

Copper has a specific gravity of 8.9 and aluminum has a specific gravity of 2.7. This means that for every gram of aluminum you need 2.7 grams of copper to produce the same volume.

The density difference between aluminum and copper can be used to determine how much more material is required for an application using aluminum rather than copper. Por exemplo, if you need 100 pounds per square foot (psf) of insulation on your transformer core, then you would need approximately 133 psf if it were made with aluminum instead of copper because 2.3 times more material would be required by the transformer manufacturer in order to achieve the same amount of insulation when comparing their densities together.

Electrical Conductivity Differences Between Transformer Aluminum Strips and Copper Strips

The resistivity of a material is the measure of its resistance to electric current. This property is important for transformers because it determines how much heat the material can withstand before melting or burning. The higher the resistivity, the more heat that can be dissipated without reaching unsafe temperatures.

- Aluminum strip has the electrical conductivity of above 60%IACS.

- While copper strip has the electrical conductivity of 99.80%IACS.

perguntas frequentes

1.What Are Aluminium Strips and Copper Strips For Transformers Winding Edges Options?

Many products managers and engineers have the trouble of transformer aluminum strips and copper strips edges.

No processo de operação real, devido à influência da dureza da tira de aço e velocidade de descarga, it is difficult to effectively control the edge of the transformer winding strip.

Contudo, depois que nosso pessoal técnico estudou por um longo tempo, encontramos uma solução para este problema. The edge finishing of our aluminium foils strips shall meet the requirements of the below figures show.

2.How Aluminum Strips For Transformers Winding Are Made?

A tira de alumínio para enrolamento do transformador é feita de material de alumínio de alta qualidade, que tem as características de alta condutividade, textura macia, superfície lisa, sem rebarbas e sem ondas. A finura da folha de alumínio pode ser controlada em 0.2 mm ou menos, e a composição e o temperamento da liga podem ser ajustados de acordo com os requisitos do cliente. A tolerância de espessura é de ±0,007 mm, a tolerância de largura é ± 1mm, a diferença diagonal é ≤1mm e a qualidade da superfície é boa.

3.How Copper Strips For Transformers Winding Are Made?

Tiras de folhas de cobre para o processo de produção de enrolamento de transformadores é usar o método de fundição e laminação contínua para produzir tiras de cobre longas com uma espessura de 0,2 mm a 1,2 mm.

O processo geral de produção de tiras de folha de cobre é:

1.Lingote de cobre fundido em produto semi-acabado;

2.O produto semi-acabado é enrolado em um produto acabado;

3.O produto acabado é recozido, e depois recozido, empacotado de acordo com as especificações, e envelhecido;

4.Use embalagens apropriadas para armazenamento ou transporte.

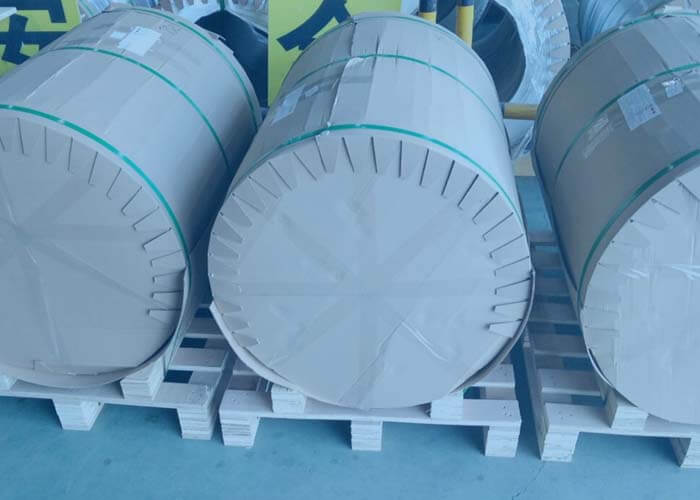

4.What is The Packaging Standard of Copper Strips and Aluminum Strips?

The packing for aluminum and copper strips for transformers is mainly about wooden pallet and wooden box.

The strip length of each roll should be same, marca de embalagem deve conter informações claras e completas.

- Palete de madeira: Pacote padrão de exportação, sem fumigação; Tamanho do palete: 1.1m x 1,1 m x 0,8 m; Peso bruto: 1 Seu; 4 paletes/20′ FCL; 8 paletes/40′ FCL Ou conforme os requisitos do cliente.

- Caixa de madeira: O pacote padrão de exportação com certificado de fumigação, pode evitar qualquer dano potencial durante o transporte.

Conclusão

Your different transformer winding project needs and priorities significantly influence which grades aluminum strips and copper strips you end up buying.

Whatever size at whatever tight tolerance of transformer winding strips you demand, HZW aqui tem certeza!