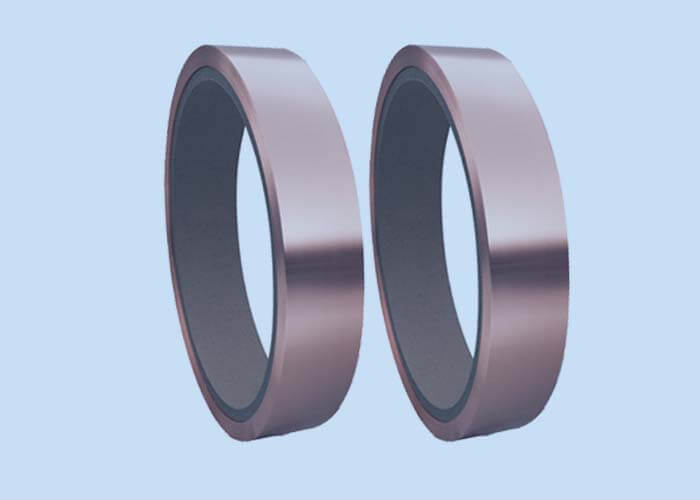

Copper Strip Tape For Power Cable Manufacturer and Supplier

Copper Strip Tape For Power Cable Quick Details

Annealed copper strip tape is mainly used as an insulation metallic screen for electric power cables with operating voltage above 3.6 kV up to 220 kV applied helically on the insulated cores or to wrap the copper screen wires.

Also used as screen in the control cables on the bedded cores.

Our copper strip tape is produced according to the American ASTM standard and China GB/T standard.

Copper Strip Tape For Power Cable Specifications

| Product Name | Power cable copper strips tapes |

| Grades | C1100/C11000/Cu-ETP CW004A/T2 |

| Temper | Annealed Soft |

| Thickness | 0.07mm-1.5mm |

| Width | 2mm-600mm |

| Edge | Slit/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 150mm, Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on special request |

| Surface Treatment | Mill finish, the strip has a smooth surface, free from scratches and impurities |

Electrical Conductivity (20℃)(IACS) | ≥100.00% |

| Applications | Transformer winding |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 7-10 working days |

| MOQ | 500 Kgs |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of copper strip tape is available |

| Remark | C1100/C11000/Cu-ETP copper strip tape can be customized |

Copper Strip Tape For Power Cable Chemical Compositions

The chemical components of grade C1100/T2 copper strip tape is summarized in the following table:

China Grade | Spec. | Range | %Cu+Ag | %Sn | %Zn | %Pb | %O | %Others |

T2 | GB/T | Min. | 99.90 | Balance | ||||

Max. | 0.002 | 0.005 | 0.005 | 0.04 | Balance |

Copper Strip Tape For Cable Grade Comparison

INDUSTRY | USA | ITALY | CHINA | EURONORM | JAPANESE | |

STANDARD | ASTM B5, B152 | UNI 5649 | GB/T | EN 1652 | DIN 1976 | JIS |

C1100 | C11000 | Cu-ETP | T2 | CW004A | E-Cu 58 | C1100 |

Copper Strip Tape For Power Cable Mechanical Properties

GB/T | ASTM | DIN | ITALY | Tensile Strength Rm | Temper (Annealed) | Vickers Hardness-Soft | Elongation(%) |

T2 | ETP/C11000 | E-Cu 58 | CU-ETP | 200-240 | O | 48-70 | ≥40 |

How About Copper Strip Tape For Power Cable Production Process?

Copper foils strips for power cable production process is to use the continuous casting and rolling method to produce long copper strips with a thickness of 0.07mm-1.5mm.

The general production process of copper foil strips is:

1.Copper ingot cast into semi-finished product;

2.The semi-finished product is rolled into a finished product;

3.The finished product is annealed, and then annealed, bundled according to specifications, and aged;

4.Use appropriate packaging for storage or transportation.

Copper Strip Tape For Power Cable: The Ultimate Guide

Power cable copper strips tapes have been used for electrical applications for more than a hundred years, and the process to make them is relatively straightforward.

This guide will cover what you need to know about choosing the best copper foil strip for your electric cable project needs, including:

What is power cable copper strip tape?

How are power cable copper strips tapes made?

Want more? Let’s keep reading!

What is power cable copper strip tape?

Cable is an important raw material in telecommunication equipment, consisting of inner conductor, insulator, outer conductor and outer sheath.

Copper or oxygen-free copper strip tape has excellent electrical conductivity, thermal conductivity and welding stability, and the outer conductor is generally made of red copper or oxygen-free copper tape.

With the development of communication technology, the requirements for cable copper tape are higher. The thickness of copper tape is thinner, the length is increased, the accuracy is improved, and stable weldability is required.

Copper strip tape is widely used in the production of cables because of its high conductivity, high precision, good welding performance and more advantages than pipe production in length.

Power cable copper strip tape features

Copper strip tape, commonly used in power cables, is a versatile material known for its excellent electrical conductivity and other beneficial properties.

Here are some features and characteristics of copper strip tape:

Electrical Conductivity: Copper is one of the most conductive metals, making copper strip tape an ideal choice for applications that require efficient electrical conductivity. It allows the smooth flow of electric current, minimizing resistance and power loss.

Corrosion Resistance: Copper exhibits excellent corrosion resistance, which helps maintain the integrity and longevity of the power cable. This resistance ensures that the copper strip tape remains stable and conductive over time, even when exposed to moisture or other corrosive elements.

High Ductility: Copper strip tape is highly ductile, meaning it can be easily shaped, bent, or formed without losing its structural integrity. This property allows for convenient installation and ensures that the tape conforms to the desired shape or contour of the power cable.

Thermal Conductivity: Copper is not only an excellent electrical conductor but also a great thermal conductor. This property allows copper strip tape to efficiently dissipate heat generated within the power cable, preventing overheating and potential damage.

Strength and Durability: Copper strip tape possesses good mechanical strength, enabling it to withstand various stresses and strains encountered during cable installation and operation. Its durability ensures that the tape remains intact and provides reliable electrical connectivity.

Easy Solderability: Copper strip tape is generally easy to solder, facilitating secure connections between the tape and other electrical components or conductors within the power cable. This feature enhances the overall reliability and performance of the cable assembly.

Malleability: Copper strip tape is highly malleable, meaning it can be easily hammered or pressed into different shapes without breaking or cracking. This property allows for flexibility in designing and manufacturing power cables, enabling customizations to meet specific requirements.

Availability and Cost-effectiveness: Copper is widely available and relatively affordable compared to other conductive materials. This accessibility and cost-effectiveness make copper strip tape a popular choice in the power cable industry.

These features collectively contribute to the widespread use of copper strip tape in power cables, ensuring efficient and reliable electrical transmission while maintaining durability and longevity.

What are power cable copper strip tape edges?

- Slit Edge

- Deburred Edge

- Round Edge

How to buy power cable copper strip tape from China?

Buyers can consider many factors when choosing a copper strip tape supplier for their power cable requirements.

A variety of online sources offer information about the availability, quality, and pricing of copper.

To buy power cable copper strips, the buyer should consider:

- The supplier’s experience in the industry.

- The quality of goods manufactured by the supplier.

- The financial stability of the supplier.

- The supplier’s delivery system.

Often these materials are not readily available in the marketplace and therefore require additional lead time for manufacturing.

To get a quote for cable copper strip tape you need to know:

- Quantity (Kgs/Tons)

- Size (Thickness x Width x Coil)

- Material Grade (C1100, T2, etc)

- Edge (Slit/Deburred/Round)

- Coil ID (200mm/300mm/400mm/500mm)

- Surface Finish (Annealed Prime)

- Hardness (45-70HV)

What is the standard sea packaging of power cable copper strip tape?

Small rolls of copper strips tapes are generally packaged in moisture-proof paper, large rolls are generally covered with waterproof plastic film or kraft paper, and then packed with wooden frame or steel frame.

Copper strips should be stored in a dry and ventilated place. It is strictly forbidden to contact with corrosive gases such as acid and alkali, corrosive liquids and hydrochloric acid, so as not to cause corrosion of copper foil strips. During transportation, it is necessary to use a moisture-proof method to prevent rain from wetting.

Copper tapes length of each roll should be same, packaging mark should have clear and complete information.

- Wooden Pallet: Standard export package, no fumigation; Pallet size: 1.1m x 1.1m x 0.8m; Gross weight: 1 Ton; 4 pallets/20′ FCL; 8 pallets/40′ FCL Or as per customer’s requirements.

- Wooden Box: The standard export package with fumigation certificate, it can avoid any potential damage during the transportation.