Stainless Steel Banding Strap

Stainless Steel Banding Strap Quick Details

Are you looking forward to having a plan or coming up with an idea to buy stainless steel banding strap products for municipal construction, signs, electrical boxes, cameras, lights, tubing fixed, substations, ship terminals and high voltage cables manufacturing?

Here you’ve come to the right place.

Check out the following buyer’s detailed guide for project engineers, operators and beginners, we’ll offer you the high quality stainless steel banding strap solutions with 24/7 custom service to fit your every idea and plan.

Contact our HZW team today to get your stainless steel banding strap solutions.

Ask Free Quote | Get Free Samples

* Indicates a Required Field

Stainless Steel Banding Strap Grades

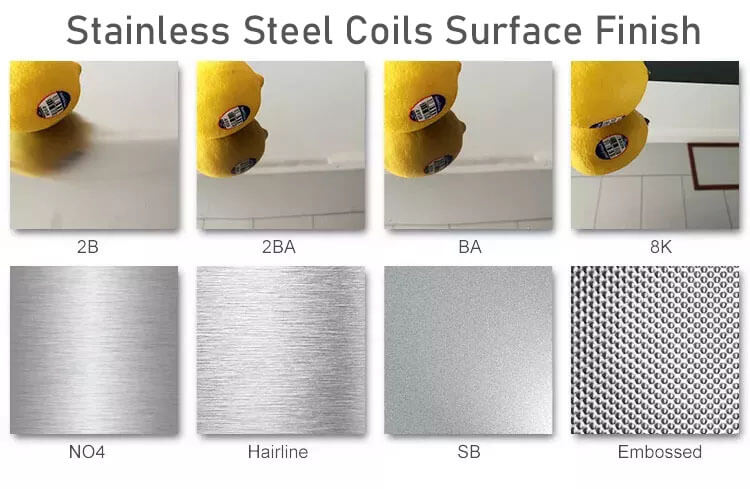

Stainless Steel Banding Strap Surface Finish

For All Your Complicated Needs

Our engineers team can help clients process quality surface finish as their requests.

Surface finish of stainless steel banding strap available: 2B, 2H(Rerolled Bright), HL (Hairline), Polishing Bright, etc.

Stainless Steel Banding Strap Applications

Stainless steel banding straps have a wide range of applications across various industries. Here are some common applications:

- Cable and Pipe Bundling

- Signage and Outdoor Applications

- Shipping and Packaging

- HVAC and Ductwork

- Marine and Offshore Applications

- Industrial Applications

- Telecom and Data Centers

- Automotive and Transportation

- Construction and Infrastructure

Stainless Steel Banding Strap Specification

| Material | Stainless Steel 430/201/304/316L |

| Thickness(mm) | 0.40/0.50/0.60/0.70/0.75/0.76 |

| Width(mm) | 4-31.4 or as customer request |

| Length/Roll(meters) | 25/30.5/50 |

| Vickers Hardness | 304/316L(150HV-180HV), 201(190HV-220HV), 430(150HV-200HV) |

| Advantages | Stainless steel banding strap in a polishing shiny finish, offers good resistance to oxidation and many moderate corrosive agents. All HZW banding strap products are with many choice width and safety round edge for installation |

| Package | Cardboard box, plastic dispenser/tote or as customer’s requests |

| Application | To bundle the pipes, tubes, cables, hydraulic hose, road signs, traffic lights, etc |

| Delivery time | Within 10 working days |

| MOQ | 1 Piece |

| Loading Port | Shanghai port or Ningbo port |

| Sample | The sample of stainless steel banding strap is available |

Stainless Steel Banding Strap Mechanical Properties

| Grade | Standard | Yield Strength Rp0.2 (N/mm²) | Tensile Strength Rm (N/mm²) | Elongation % | Hardness (HV) | Hardness (HRB) |

|---|---|---|---|---|---|---|

| 201 | ASTM A240 | ≥ 275 | ≥ 520 | ≥ 35 | ≤ 260 | ≤ 101 |

| 202 | ASTM A240 | ≥ 275 | ≥ 520 | ≥ 40 | ≤ 218 | ≤ 95 |

| 301 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 304 | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 210 | ≤ 92 |

| 304L | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 316L | ASTM A240 | ≥ 177 | ≥ 480 | ≥ 40 | ≤ 200 | ≤ 90 |

| 316Ti | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 317L | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 218 | ≤ 95 |

| 309S | ASTM A240 | ≥ 205 | ≥ 515 | ≥ 40 | ≤ 218 | ≤ 95 |

| 310S | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 321 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

| 347 | ASTM A240 | ≥ 205 | ≥ 520 | ≥ 35 | ≤ 200 | ≤ 90 |

| 410S | ASTM A240 | ≥ 205 | ≥ 440 | ≥ 20 | ≤ 210 | ≤ 92 |

| 420J2 | ASTM A240 | ≥ 225 | ≥ 540 | ≥ 18 | ≤ 180 | ≤ 80 |

| 430 | ASTM A240 | ≥ 206 | ≥ 450 | ≥ 22 | ≤ 200 | ≤ 88 |

| 2205 | ASTM A240 | ≥ 450 | ≥ 620 | ≥ 25 | ≤ 293 | ≤ 30 |

| 2507 | ASTM A240 | ≥ 450 | ≥ 620 | ≥ 25 | ≤ 290 | ≤ 30 |

| 253 MA® | ASTM | ≥ 310 | ≥ 600 | ≥ 40 | ≤ 217 | ≤ 95 |

| 254 SMO® | ASTM | ≥ 300 | ≥ 650 | ≥ 35 | ≤ 223 | ≤ 96 |

| 654 SMO® | ASTM | ≥ 430 | ≥ 750 | ≥ 40 | ≤ 250 | ≤ 100 |

| 904L | ASTM | ≥ 216 | ≥ 490 | ≥ 35 | - | ≤ 90 |

| UNS N08926 | ASTM | ≥ 295 | ≥ 650 | ≥ 35 | - | ≤ 100 |

| UNS S17400 | ASTM | ≥ 725 | ≥ 930 | ≥ 10 | - | - |

Stainless Steel Banding Strap: The Ultimate Guide

Stainless steel banding straps are produced using stainless steel strips and the process of slitting and edging.

This banding strap product has characteristics such as good corrosion resistance, good processability, high strength and toughness, good workability and so on.

So what’s the grade? What’s the production process? What’s the packaging types?

In this guide, we will show you details about all.

Check out the following buyer’s detailed guide for project engineers, operators and beginners, we’ll offer you the high quality stainless steel banding strapping solutions with 24/7 custom service to fit your every idea and plan.

What Are Stainless Steel Banding Straps?

The stainless steel banding strap is also called stainless steel banding tape. Moisture can cause normal steel banding to rust, so stainless steel used indoors and outdoors where long exposures to high humidity.

According to the processing method, the stainless steel banding strap edge can be produced as slit and round types.

All banding products from HZW are with round edge for safe installation.

The conventional thickness is between 0.25mm and 1.0mm, and the width is between 4.6mm and 31.75mm.

Different length can be produced according to your detailed request.

Polishing bright stainless steel banding strapping has many advantages such as smooth and flat shiny surface, high accuracy, good mechanical properties, and offers good resistance to oxidation and many moderate corrosive agents.

Grade 201 stainless steel banding strap has superior yield and tensile strength properties to provide maximun clamping strength for different application. Grade 201 stainless steel is a lower-cost alternative to the conventional Cr-Ni austenitic stainless steels, such as 304 steel.

As you know, 201 vickers hardness is above 190HV. And 304 or 316 grade hardness is range from 150HV to 180HV.

304 grade is a common material in stainless steel area, with a density of 7.93 g/cm³, which is also called 18/8 stainless steel in the industry. GB standard is 0Cr18Ni9.

Grade 304 stainless steel banding strapping is most common used and can be applied in almost any environment.

Grade 316 stainless steel banding strap are specialized for seaside cities or extreme corrosive enviroment, such as the chemical factory or oil field application.

Contains aluminum, so the resistance to pitting corrosion in marine and chemical industrial environments is much better than 304 stainless steel.

316L stainless steel is almost identical to 316 grade. 316L stainless steel banding strapping has lower carbon content imparts even better corrosion resistance than 316 grade.

Stainless steel banding strapping product is widely used in municipal construction, signs, electrical boxes, cameras, lights, high voltage cable, tubing fixed, substations, ship terminals, and other industries.

How Stainless Steel Banding Straps Are Made?

Stainless steel banding straps, also known as stainless steel bands or stainless steel strapping, are commonly used for securing and bundling items in various industries. Here’s a general overview of how stainless steel banding straps are typically made:

Material Selection: Stainless steel banding straps are made from high-quality stainless steel, typically of grade 201, 304 and 316L. These grades offer excellent corrosion resistance and durability.

Slitting: The first step involves slitting large stainless steel coils into narrower strips. The width of the strips will depend on the desired width of the final banding straps. Slitting machines are used to cut the stainless steel coils with precision.

Edge Conditioning: The edges of the stainless steel strips are often processed to ensure smoothness and remove any sharp burrs or irregularities. This step helps prevent injuries during handling and installation.

Forming: The stainless steel strips are then shaped into the desired form, typically a flat and thin strap. This is done by passing the strips through a series of rolling mills or forming machines, which apply pressure to shape the metal into the desired profile.

Deburring: After forming, the stainless steel banding straps may undergo a deburring process to remove any remaining sharp edges or rough surfaces. This is crucial for safety purposes, as it eliminates potential hazards during handling.

Surface Finish: The stainless steel banding straps may undergo surface treatments to improve their appearance and resistance to corrosion. Common surface finishes include bright annealing, pickling, or applying a protective coating.

Cutting to Length: The continuous stainless steel strap is cut into individual lengths according to the desired size or customer specifications. This can be done using automatic cutting machines or manually, depending on the production setup.

Coiling and Packaging: The finished stainless steel banding straps are typically coiled and packaged for shipment. They may be wound onto spools, packed in coils, or placed in boxes or containers, ready for distribution.

It’s important to note that manufacturing processes may vary among different manufacturers, and specialized equipment and techniques might be used to achieve specific product features or customization options.

What Are The Advantages of Using Stainless Steel Banding Straps?

High strength and durable: You cannot doubt the strength of any stainless steel strip. It can be used in extreme conditions without breaking.

Weather-resistant: Since it can still serve its purpose even in the harshest weather conditions, including the subsea applications.

Different sizes and dimensions: You can easily choose one that will fit your application.

Cost-saving: you will be able to save a significant amount of money in the long term.

What Are The Edges Options of Stainless Steel Banding Strap?

Rounded edges reduce the risk of injury during handling and installation. Sharp edges can cause cuts or punctures, especially when working with tensioning tools or when manually handling the banding straps. By rounding the edges, the likelihood of accidental injuries is significantly reduced.

What Is The Packaging Standard of Stainless Steel Banding Strap?

- Standard export sea packaging:

Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case; - Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

- Other special packaging will be designed as customer’s request;

Eye to wall and eye to sky are both available; - By International Express: DHL/UPS/FEDEX/EMS and our own express line;

- By air or By sea;

- Shipping port: Shanghai, Ningbo or as your request.

How To Use A Steel Banding Tool?

Choosing the Best Stainless Steel Banding Strapping Supplier in China

In terms of current and future supply chain demands, our team is committed to providing global users with the best banding strapping solutions of high quality stainless steel banding straps.

We have a professional and efficient team that will support quick response for you. Just ask for a quick quote, whether you are already our customer or not, we will be available online 24/7 to support your project.

What Is The HS Code of Stainless Steel Banding Strap?

- 73269019.00

Contact Us

We welcome all inquiries from clients and If you have any questions about our metal strips solutions and services, please reach out to us via the below contact form.

We will reply you as soon as possible.

Every Interaction Counts!

* Indicates a Required Field