World's Leading Stainless Steel Strips Industry Corporation

Stainless Steel Strips And Metal Strips Solutions

About Us

Advanced Manufacturing Excellence With Quality At It's Best!

HZW technology is one of leading stainless steel strips suppliers in China, our expert team supply stainless steel strip solution with 16 years rich experience.

In terms of current and future supply chain demands, our team is committed to providing global users with the best metal strips solutions of high quality stainless steel strips, stainless steel coils, special alloy strips and non-ferrous alloys strips.

We have a professional and efficient team that will support quick response for you. Just ask for a quick quote, whether you are already our customer or not, we will be available online 24/7 to support your project.

What Stainless Steel Strips Grades We Have

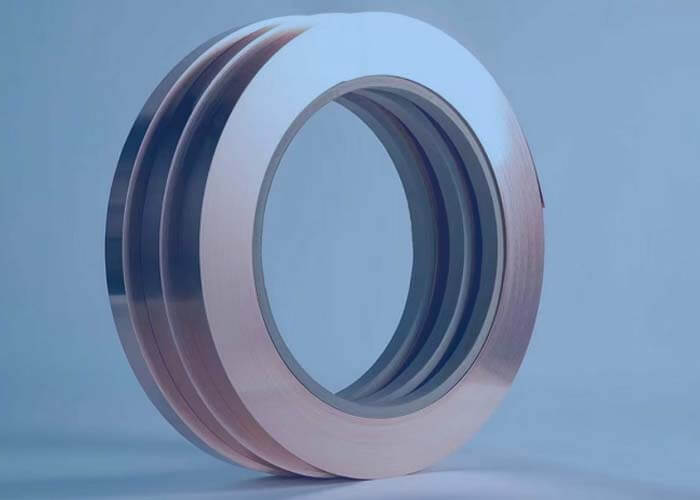

Special And Non-Ferrous Alloys Strips Solutions

We are the precision metal strips industry heads and produce the most reliable and trendy solutions you are looking for.

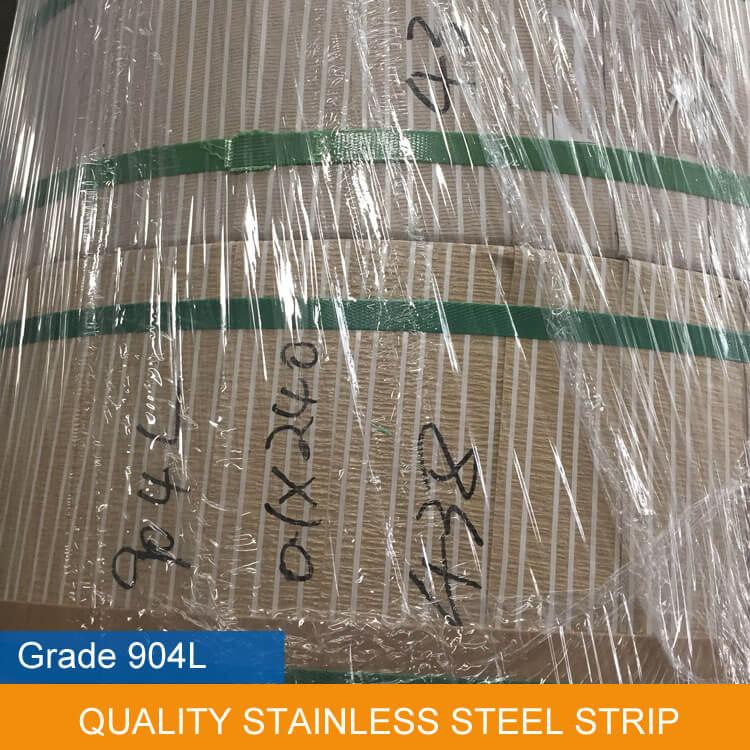

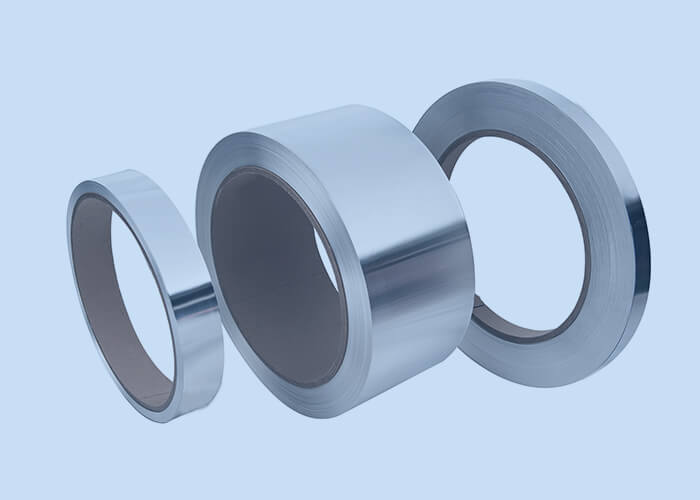

Stainless Steel Strips

Stainless steel strip is widely used in the sectors of special requirements such as button battery, welding pipe, stainless steel flexible hose, finned tube, stamping part, tact switch, engine gasket, spring gasket, gas filter lid, power cable shield, clamp, hypodermic needle and tower metal random packing pall ring components.

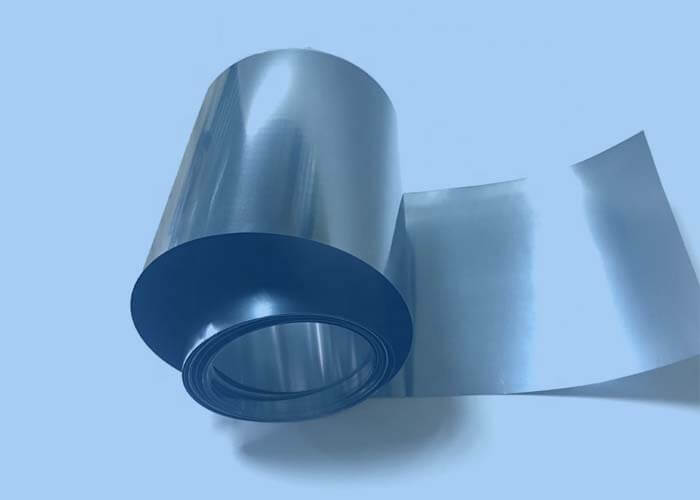

Stainless Steel Foils

Your demands, our pursuit.

Grade and thickness can be customized as your request.

The only place where you’ll get the perfect metal strip solutions for all your industry needs.

4 Reasons Why Choose Us

16 Years Professional Metal Strip Expert

Every stainless steel strip you want to purchase from China, we can always help. Check Case Study

High Quality

Every sold cargo from our factories will be total inspected by our quality assurance department before shipment. Check Case Study

Competitive Price

Global sourcing management ensure the quality of mother coils.

Meantime we are the long term partners of prime stainless steel mill origin which can support us good price of raw materials. Check Case Study

24/7 Online Support & Free Quote

A complete set of customer management system support.

Within the scope of our ability, get a free quote or ask any questions. Check Case Study

We are not just delivering the cargo, we deliver trust!

Precision We Deliver!

Focus On Precision Stainless Steel Strips Technology

Being Meticulous Is Our Responsibility

Deburring Innovation Technology

Metal Foil&Strip Edge Controlling and Free Of Burrs

- Burr Length≤0.03mm

- Round Edge

- Free of Burr

- Using Auto Tools

- Deburring on Both Surface Finish

Coil Inside Diameter Innovation Technology

ID 150mm, 200mm, 300mm, 400mm and 500mm

- ID&OD As Your Request

- Cardboard Core

- Plastic Core

- Steel Core

Trusted By Over 1k+ Global Companies

Commonly Asked Questions

- The easiest way to find your stainless steel strips supplier in China is by searching “ [stainless steel strips]+suppliers China.”

- Your stainless steel strips supplier should provide you the best solution as soon as possible.

- Your stainless steel strips supplier should provide competitive price and good service to support your projects.

If the samples are ready on stock, the MOQ will be less. A4 paper size is workable.

If you need customized ones, the trial order MOQ is 1000kgs.

Making sure 100% inspection depend on international standards according to customer’s requirements.

We have advanced inspection equipment which can ensure the high quality of the finished metal strips.

We have powerful stock of many grade stainless steel strips. If the your request samples are the same thickness in our stock, we will deliver them by international express for free.

We are expert manufacturer in precision stainless steel strips production with 16 years of experience.

- Checking and packaging your goods well before shipment.

- Do reinforce your goods well in the container.

- Discussing with our shipping agent and loading a reasonable amount of goods in the container.

- Standard export wooden pallet or wooden case packaging.

- Also we can meet special design packaging as your request.

- Deliver metal strip in coil, hard paper core inside. Eye to wall and eye to sky are both available.

- Grate car is taken to avoid any damage which might be caused during storage or transportation.

It depends on your order total quantity and stock of these special alloy mother coils.

Usually from the start of the order to the completion of production for about 2-3 weeks.

Blog & News

Blog | March 15, 2021

Blog | August 16, 2020

For stainless steel strip production process, here you will be able to get a clear understanding of how to manufacture it with precision excellence technology.

Blog | January 11, 2021

Stainless steel strip, also called stainless steel strip coil and strip stainless steel. If you are the beginner of this area, you will be an expert through this guide.

Blog | December 11, 2020

Stainless steel strips are the extension products of ultra-thin stainless steel plates, usually long and narrow stainless steel strips are manufactured to meet the demands of various industrial and mechanical areas.

Read More

Useful Guides Related Stainless Steel Strip

How To Choose Right Stainless Steel Strip For Your Project

If you are the beginner of this area, you will be an expert through this guide.

The proportion of the nickel and chromium added is different, and the mechanical properties and application fields of the stainless steel strip produced are different.

It is mainly manifested in the following 12 aspects.

- Standard

- Grade

- Application

- Thickness

- Width

- Tolerance Of Thickness And Width

- Coil Inner Diameter

- Surface Treatment

- Edge

- Mechanical Properties

- Weight

- Packaging Type

What Is Cold Rolled Stainless Steel Strip

End users’ requirements for cold rolled stainless steel strips are becoming increasingly strict in modern days.

Unlike conventional hot rolled stainless steel strips, precision cold rolled stainless steel strips usually refer to stainless steel strips with a thickness of less than 0.30mm.

As a high-end product in the field of stainless steel materials, precision cold rolled stainless steel have excellent strength, precision, surface finish and other properties. They are widely used in heat exchangers, optical cables, hypodermic needles, diamond blades, and springs materials.

At present, the main production processes of cold rolled stainless steel strip include cold rolling, bright annealing, tension straightening and finishing.

What Is Hot Rolled Stainless Steel Strip

Hot rolled stainless steel strip is a strip with a thickness of 1.80mm to 6.00mm and a width of 50mm to 1200mm produced by a hot rolling mill.

Hot rolled stainless steel material has many advantages such as low hardness, easy processing and good ductility.

The hot rolled stainless steel strip is made of hot rolled stainless steel coil after further hot rolling and slitting.

Its production process includes pickling, high temperature rolling, process lubrication, annealing, smoothing, cutting and packaging.

Compared with cold rolled stainless steel strip, it has higher dimensional accuracy, low surface roughness, good surface quality and high strength.

Therefore, thinner hot rolled strips can be used in place of thicker cold rolled strips for the same purpose to save stainless steel consumption, which has great economic significance.

Hot rolled stainless steel strips are divided into main five types according to their organizational characteristics: austenite, austenite-ferrite, ferrite, martensite and precipitation hardening, which can be selected in real application.

What’s The Difference Between Grade 304 And 304L Stainless Steel Strip

“L” does not mean that the length of the 304L stainless steel strip is longer than 304 stainless steel strip coil.

304 and 304L stainless steel strips are common materials and widely used in many industries.

The difference between 304 stainless steel strip and 304L stainless steel strip is not only the carbon chemical components.

Grade 304 stainless steel strip and 304L stainless steel strip belong to austenitic stainless steel, and the corrosion resistance of austenitic stainless steel comes from the chromium oxide protective layer formed on the surface of the stainless steel.

Assuming that the surface finish of stainless steel strip is heated to a high temperature range between 450°C and 900°C, carbon may precipitate in the grain boundary in the form of carbides, and at the same time, a chromium-depleted zone is formed, and the structure of the stainless steel strip will change.

This will form chromium carbide at the edge of the grain boundary.

There is no way to protect the original chromium oxide protective layer, which increases the susceptibility to intergranular corrosion, and leads to a decrease in the corrosion resistance of the treated stainless steel strip.

This corrosion is called “intergranular corrosion“.

What’s The Difference Between 316 And 316L Stainless Steel Strip

Due to their excellent corrosion resistance, 316L stainless steel strip and 316 stainless steel strip have a wide range of applications in the chemical industry.

316 and 316L stainless steel strips are both austenitic stainless steel strips.

316 and 316L stainless steel strips are stainless steels containing molybdenum.

The molybdenum content in 316L stainless steel strip is slightly higher than 316 stainless steel strip.

Due to the molybdenum in the stainless steel, the overall performance of 316 and 316L stainless steel strip is better than 304 stainless steel strip.

As a low-carbon series of 316 stainless steel, in addition to having the same characteristics as 316 stainless steel, 316L stainless steel has excellent grain boundary corrosion resistance.

Under high temperature conditions, when the concentration of sulfuric acid is lower than 15% and higher than 85%, 316 stainless steel strip has a wide range of uses.

316 stainless steel strip also has good chloride corrosion properties, so it is usually used in marine environments.

316L stainless steel strip has a maximum carbon content of 0.03, which can be used in applications that cannot be annealed after welding and require maximum corrosion resistance.

What’s The Difference Between 2205 And 2507 Stainless Steel Strip

2205 and 2507 stainless steel strips are stainless steels containing molybdenum.

The molybdenum content in 2507 stainless steel strip is slightly higher than 2205 stainless steel strip.

Due to the molybdenum and high chromium contents in the stainless steel, the overall performance of 2205 and 2507 stainless steel strip is better than 317L stainless steel strip.

The duplex structure of 2507 gives it strong resistance to stress corrosion cracking.

Due to its higher alloy content, the corrosion resistance and strength of 2507 stainless steel strips are better than 2205 stainless steel strips.

2507 stainless steel is especially suitable for offshore oil and gas mining equipment.

How To Buy Stainless Steel Strips From China

Searching resources from internet is the fastest way to get the China suppliers information from Google, Alibaba platform, 51 BXG website, etc.

Whenever the need for finding information of stainless steel strips, the first source we go to is usually Google. The easiest way to find stainless steel strips manufacturers on Google is by searching “ [stainless steel strips]+manufacturers in China.”

Google is a fast way to find Chinese metal strips companies, but it also brings some unknown risks and low efficiency level. Usually it will display more than millions results of searching related information.

You have no idea how to choose the right and trustworthy suppliers here. So you have to put each one of them through a strict screening sequence process. And it will waste a lot of time and effort of every new purchaser.

In the hundred year history of stainless steel development, there are many grades of stainless steel for different applications.

And different mill origin offered special alloy products also have some little differences in appointed applications.

Before purchasing stainless steel strips from China market, you should know your customer applications or yours.

For example, 304 stainless steel strip is widely used in tower random packing pall ring production. So using 904L stainless steel strip material for this application can not improve economic performance. It is not necessary for buying super duplex steel for them.

At first, you should know how to choose the right grade material for your application and project.

Secondly you should confirm more details of strips with Chinese suppliers together. Such as standards, thickness, width, tolerance, hardness range, surface finish treatment.

Thirdly, you will receive many official quotation documents from different suppliers from China. You should remove the most peak price and the lowest one from some of them. Then pick up the middle good price from one of these suppliers.

During this process, you will know more about China manufacturers service and quality system.

How To Produce 1 Roll Stainless Steel Strip

What Is One Roll Stainless Steel Strip Used For

Stainless steel strip is also known as stainless steel strip coil, which is widely used in the sectors of special requirements such as button battery, welding pipe, stainless steel flexible hose, finned tube, stamping part, tact switch, engine gasket, spring, gas filter lid, power cable shield, clamp, injection needle and tower metal random packing pall ring components, etc.

And it is mainly added nickel and chromium contents for having the abilities of good formability and corrosion resistance for other industry applications.

The stainless steel strips can be divided into normal austenitic grade, ferritic grade, martensitic grade, duplex grade, precipitation hardening grade and super austenitic grade.

Meanwhile, in a lot of supporting precision demands of electronics manufacturing and medical area, often used precision stainless steel foils.

Before we share the production process of 1 roll stainless steel strip for you, you could get a quick glance for left video showcase.

Technical Analysis

Why we should mention this detail firstly?

For new customers, they should know how to buy steel strips products from suppliers.

During this business deal, customers should confirm all technical details of products with manufacturers together.

Meanwhile, suppliers should organize a related technical meeting to analyze technical issues before every strip new production.

It can help avoid more contract and after-sales problems between clients and factories, to a large extent, still is a good beginning.

Technical analysis includes products grade, production related standard, precision tolerance control, strip hardness, tension strength,slitting edges and special sea packaging details, etc.

Raw Material Preparation

We are working with many famous and advanced steel manufacturers worldwide.

Our procurement supply chain management department and systems strictly control the quality of each mother coil product.

The stainless steel coils mill origin such as TISCO, JISCO, BAOWU, POSCO, OUTOKUMPU.

Checking the mother coil raw material after they reach our factory, it is called incoming quality control.

Checking details include products thickness tolerance, width of coil, outside packaging, label marks, inside surface finish, chemical components, etc.

Rolling And Bright Annealing Process

- The first time rolling process: Our workers operate the advanced mill calender to make the hot rolled stainless steel mother coil with a thickness of 2.0mm~3.0mm into a stainless steel strip coil with a thickness range of 0.2mm~1.0mm. The first time bright annealing process: The 0.2mm~1.0mm thickness stainless steel strip is processed for bright annealing treatment. The strip can be fast cooled by the the continuous annealing line. The traveling speed of the stainless steel strip on the line is around 60m~80m/min.

- The second time rolling process: After first time bright annealing process, continuing rolling the stainless steel strip with 0.2mm~1.0mm thickness into a new stainless steel strip with a thickness of 0.1mm~0.3mm.

- The third time rolling process: After second time bright annealing process, continuing rolling the stainless steel strip with 0.1mm~0.3mm thickness into a new stainless steel strip with a thickness of 0.06mm~0.15mm.

- The forth time rolling process: After third time bright annealing process, continuing rolling the stainless steel strip with 0.06mm~0.15mm thickness into a new stainless steel strip foil with a thickness of 0.02mm~0.1mm.

Degrease Cleaning Process

Cleaning the residual oil on the surface of the stainless steel strip due to the stains during the rolling process.

The principle is to use the chemical reaction (saponification reaction) between the alkaline agent and the grease on the surface of the steel strip to remove the grease.

The speed of the whole unit line is about 60meters/min, which can handle stainless steel strip with 0.02mm-1.0mm thickness.

Tension Straightening Process

When stainless steel strip is rolled on a 20-high rolling mill with a thickness of 0.02mm-0.8mm, it is a difficult-to-deform metal.

Defects formed when the reduction of half the width of the steel strip is slightly larger.

It behaves like a very wide unilateral wave. This wave has a very low amplitude and a very long wavelength.

The main reason is the poor “plate shape” of the metal coil plate or the asymmetry of the position of the middle roller.

The manifestation is that the edges of the steel strip are slightly bent, which is more obvious after slitting process.

Under the condition of complete softening and large tension leveling, the use of stretch bending straightening is the only method that can eliminate the stress of steel strip.

In this straightening process, the steel strip is stretched under a controllable tension.

In this process, the steel strip passes through a set of slightly offset rollers and bends, causing the steel strip to slightly stretch.

After straightening, the stress distribution in the entire steel strip is more uniform and the plate shape is more straight.

Even after slitting, blanking, stamping, forming and polishing, it always has this good feature.

Originally, the various “plate shape” defects discussed above are caused by uneven extension during rolling.

In the stretching and bending straightening process, additional tension is applied to the insufficiently deformed area to reduce the plate shape defects by more than 90%.

The tension leveler unit line is equipped with plate automatic control system.

The excellence control and management to production process assures the straightness of metal strip with variety hardness temper.

Slitting Process

For different thickness of strip coils slitting process, the small and large slitting machines will be used by our team. Our larger slitting machines can cut hot rolled mother coils from mill origin directly. Thickness is from 2mm to 6mm.

And meantime we use the small machines to cut the narrow strip coils as precision strips. Thickness is from 0.02mm to 1.0mm.

Our workers will make adjustments between coils and cutting tools when they are preparing to slit in order to minimize the burr of strips edge as much as possible.

Inspection Process

We have full inspection and routing inspection during metal strips mass production.

Checking the stainless steel strips after they are produced carefully.

The advanced inspection and measurement equipment will support every inspection process.

After all end products are finished, the quality control department deal with the following inspections, such as metallographic analysis, mechanical performance testing, straightness testing, plate shape, surface finish, thickness and width tolerances inspection.

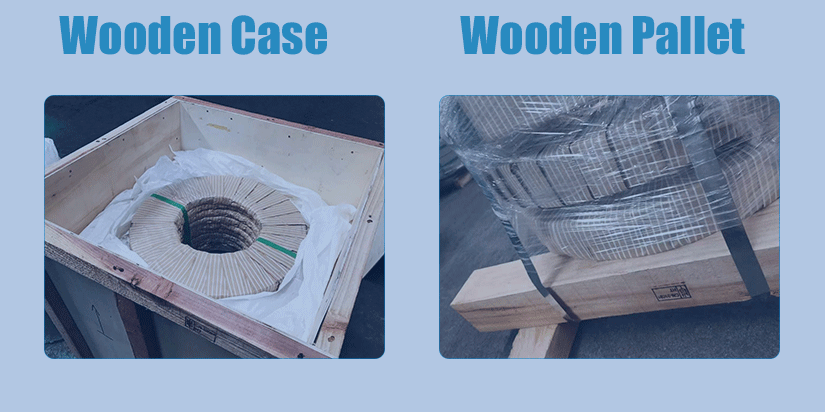

Packaging Process

To a certain extent, exquisite standard sea packaging reflects one supplier‘s service. It greatly influences the client’s next purchasing plans.

One kind of packaging is called wooden pallet. And the fumigation wooden pallets and non-fumigation pallets are two kinds of pallets type.

Eye to eye or eye to wall types of packaging strips will be adopted before shipment.

The surface finish of metal strips will be packaged with waterproof paper. Then coating the PVC film on this paper.

After that, the banding strap will be used for fastening pallets and strips products.

Before placing the metal strips into the wooden case, the strips are packaged with perfect packaging.

Wooden case and four corners shall not be smaller than the outer diameter of the total strips.

In addition, clear labels are tagged on the outside of these sea standard packages for easy identification of these metal strips specifications and quality information.

What Is Stainless Steel Strip Surface Treatment

NO.1 Surface Treatment

NO.1: No. 1 surface refers to the surface obtained by heat treatment and pickling after hot rolling of the stainless steel strip.

It is to remove the black oxide scale produced during hot rolling and heat treatment by pickling or similar treatment methods.

This is No. 1 surface processing. The No.1 surface is silvery white and matt.

No.1 hot rolled 316L stainless steel strip are mainly used in heat-resistant and corrosion-resistant industries that do not require surface gloss, such as alcohol industry, chemical industry and large containers.

2D Surface Treatment

Compared with the common 2B surface finish, the smoothness of the 2D surface is lower than the 2B surface.

But the overall surface of 2D is still very uniform and matt.

The 2D surface finish is generally heat treated and pickled after cold rolling, and then smoothed with a matt roller.

Whether it is in the China national standard, or the Japanese standard, the American standard, and the European standard, there are detailed specifications for the 2D surface finish.

2B Surface Treatment

2B: The surface of 2B is different from the 2D surface in that it is smoothed with a smooth roller, so it is brighter than the 2D surface.

The surface roughness Ra value measured by the instrument is 0.1~0.5μm, which is the most common processing type.

This kind of stainless steel strip surface is the most versatile, suitable for general purposes, which is widely used in the chemical, paper, petroleum, medical and other industries, and can also be used as a building curtain wall.

TR Hard Finish Surface Treatment

TR Hard Finish: TR stainless steel is also called hard steel.

Its representative steel grades are 304 stainless steel strip and 301 stainless steel strip, they are used for products that require high strength and hardness, such as railway vehicles, conveyor belts, springs and gaskets.

The principle is to use the work hardening characteristics of austenitic stainless steel to increase the strength and hardness of the steel plate by cold working methods such as rolling.

The hard material uses a few percent to several tens of percent of the mild rolling to replace the mild flatness of the 2B base surface, and no annealing is carried out after rolling.

Therefore, the TR hard surface of the hard material is the rolled after cold rolling surface.

2H Surface Treatment

Rerolled Bright 2H: After the rolling process. the 904L stainless steel strips will be processed bright annealing.

The strip can be fast cooled by the the continuous annealing line.

The traveling speed of the stainless steel strip on the line is around 60m~80m/min.

After this step, the surface finish will be 2H rerolled bright.

Polishing Bright Surface Treatment

Mechanical polishing type is a polishing method that relies on cutting and plastic deformation of the material surface to remove the polished convexities to obtain a smooth surface of polished stainless steel strip.

Generally, oil stone sticks, wool wheels and sandpaper are chose with manual operations.

During 201 stainless steel strip for banding strap production, the polishing finish will be needed.

NO.4 Surface Treatment

No.4: The surface of No. 4 is a fine polished surface finish that is brighter than the surface of No. 3.

It is also obtained by polishing the stainless steel cold-rolled stainless steel plate with 2 D or 2 B surface as the base and polishing with abrasive belt with a grain size of 150-180# Machined surface.

The surface roughness Ra value measured by the instrument is 0.2~1.5μm.

NO.4 finish grade 430 stainless steel strip surface is widely used in restaurant and kitchen equipment, medical equipment, architectural decoration, containers, etc.

HL Surface Treatment

HL: HL surface is commonly called hairline finish. Japanese JIS standard stipulates that 150-240# abrasive belt is used to polish the continuous hairline-like abrasive surface obtained.

In China’s GB3280 standard, the regulations are rather vague.

HL surface finish is mostly used for building decoration such as elevators, escalators, and facades.

BA Surface Treatment

BA: BA is the surface obtained by bright heat treatment after cold rolling.

Bright heat treatment is annealing under a protective atmosphere that guarantees that the surface is not oxidized to preserve the gloss of the cold-rolled surface, and then use a high-precision smoothing roll for light leveling to improve the surface brightness.

This surface is close to a mirror finish, and the surface roughness Ra value measured by the instrument is 0.05-0.1μm.

BA surface has a wide range of uses and can be used as kitchen utensils, household appliances, medical equipment, auto parts and decorations.

NO.8 Surface Treatment

No.8: No.8 is a mirror-finished surface with the highest reflectivity without abrasive grains.

The stainless steel deep processing industry also calls as 8K plates.

Generally, BA materials are used as raw materials for mirror finishing only through grinding and polishing.

After mirror finishing, the surface is artistic, so it is mostly used in building entrance decoration and interior decoration.

Blue PE Film Coating For Bare Stainless Steel Strip

The blue PE protective film is produced by adding blue pigment to the transparent plastic coating to make the original film, and then applying oil-based adhesive or water-based adhesive through coating technology.

Generally blue PE films are divided into two types, one is water glue PE blue protective film, and the other is oil glue PE blue protective film.

The blue PE protective film inherits the performance of the PE protective film, and the blue PE protective film uses a special polyethylene (PE) plastic film as the base material.

According to the density, it is divided into high-density polyethylene protective film, medium-density polyethylene and low-density polyethylene.

After the surface treatment, we use blue PE film to protect the surface of bare stainless steel strip.

The Meaning Of Letter H In 301 Stainless Steel Strip

“H” is the Japanese JIS G4313 cold-rolled stainless steel strip standard for springs production.

The H and mechanical properties detailed information of grade 301 stainless steel strip is summarized in the following table:

| Grade | Status | Hardness | Yield Strength | Tensile Strength | Elogation |

| HV | Mpa | Mpa | % | ||

| SUS301 | ANN | ≤218 | ≥205 | ≥520 | ≥40 |

| 1/4H | 250-310 | ≥470 | ≥780 | ≥25 | |

| 1/2H | 310-370 | ≥510 | ≥930 | ≥18 | |

| 3/4H | 370-430 | ≥745 | ≥1130 | ≥5 | |

| FH | 430-490 | ≥1030 | ≥1320 | ≥4 | |

| EH | 490-550 | ≥1275 | ≥1570 | ≥3 | |

| SH | ≥550 | ≥1550 | ≥1750 | ≥1 |

The Meaning Of Letter J In 201 Stainless Steel Strip

201 stainless steel strip are made from many kinds of 201 grade mother coils. Do you know the meaning of letter J in 201 stainless steel strip?

If you are the beginner of this area, you can benefit from this guide.

Let’s keep reading.

Since there is no unified standard, there are currently five grades of 201 stainless steel strips in China.

J1, J2, J3, J4 and J5 due to different compositions and application fields.

These Chinese-made 201 stainless steel strip includes more than 1% nickel contents. But international standard of Ni content is around 3.5%.

The biggest difference is the copper chemical content.

The higher the copper content, the more expensive the price.

Copper chemical content(%): J4>J1>J3>J2>J5;

Carbon chemical content(%): J5>J2>J3>J1>J4;

Hardness level: J2>J3>J1>J4;

Price level: J4>J1>J3>J5.

What Is Stainless Steel Strip Packaging

Usually, the wooden case and wooden pallets are the two main types for stainless steel strips packaging. Eye to wall and eye to sky are both available.

- Firstly, waterproof paper is winding with bare stainless steel strips.

- Secondly, using plastic or steel banding strap to band stainless steel strips with wooden pallets together.

- Thirdly, using PVC film to package all stainless steel strips with pallets.

In addition, clear labels are tagged on the outside of these packages for easy identification of these strips measurements and quality information.

The fumigation wooden pallets and non-fumigation pallets are two kinds of wooden pallets types.

Because of the limit and customs requirements of various countries, so non-fumigation wooden pallets are widely used.

What Is The Hs Code Of Stainless Steel Strip

To find out the detailed HS code of related stainless steel strip, you need to determine the specifications and applications of the stainless steel strip.

The following are the part of stainless steel strip HS code

- 7220202000——Cold rolled stainless steel strip with thickness below 0.35mm

- 7220203000——Cold rolled stainless steel strip with thickness from 0.35mm to 3mm

- 7220204000——Cold rolled stainless steel strip of a thickness 3mm or more, and width less than 600mm

Looking For Solutions In Metal Strips Industry

Contact Us

We welcome all inquiries from clients and If you have any questions about our metal strips solutions and services, please reach out to us via the below contact form.

We will reply you as soon as possible.

Every Interaction Counts!

* Indicates a Required Field