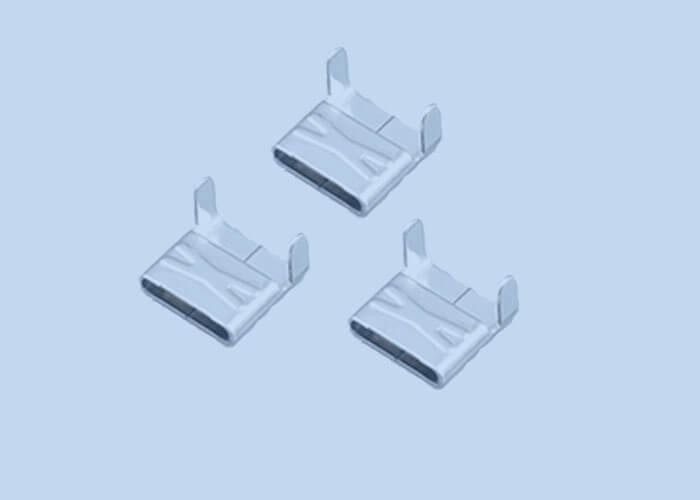

Stainless Steel Banding Buckles

Stainless Steel Banding Buckles Quick Details

Stainless steel banding buckles are also called stainless steel banding clips.

It is designed for light duty purpose, to be used together with bare stainless steel banding strap or insulated stainless steel banding strap.

Special tensioning tools are also required for installing these banding strap buckles.

The stainless steel buckles are made of 201, 202, 304 and 316L stainless steel materials. It is formed by stamping process.

It has the characteristics of smooth surface, no burr on the edges and corners, rust prevention, corrosion resistance, cold resistance, high temperature resistance, convenient use and large bearing capacity.

Ask Free Quote | Get Free Samples

* Indicates a Required Field

Stainless Steel Banding Buckles Grades

Stainless Steel Banding Buckles Specification

| Raw Material | Stainless Steel Steel ASTM A240 Grade 201/304/316L |

| Vickers Hardness | 304/316L(150HV-180HV), 201(190HV-220HV), 430(150HV-200HV) |

| Package | Plastic bags in carton box or as customer’s requests |

| Application | To bundle the pipes, tubes, cables, hydraulic hose, road signs, traffic lights, etc. |

| Delivery time | Within 10 working days |

| MOQ | 1 Piece |

| Loading Port | Shanghai port or Ningbo port |

| Sample | The sample of stainless steel banding buckle is available |

Stainless Steel Banding Buckles Features

- Stainless steel banding buckles can be used with many types of stainless steel band providing fastening strength.

- Stainless steel banding buckles for standard duty applications including hose assemblies, cable bunding and general fastening.

- 201/304/316L stainless steel offers good resistance to oxidation and many moderate corrosive agents.

- You can hold a single or double wrapped band configuration.

- Band clamps can be formed over any contour shape.

Stainless Steel Banding Buckles Applications

- Cable and Pipe Bundling

- Signage and Outdoor Applications

- Shipping and Packaging

- HVAC and Ductwork

- Marine and Offshore Applications

- Industrial Applications

- Telecom and Data Centers

- Automotive and Transportation

- Construction and Infrastructure

Stainless Steel Banding Buckles: The Ultimate Guide

Are you looking forward to having a plan or coming up with an idea to buy stainless steel banding buckles products for municipal construction, signs, electrical boxes, cameras, lights, tubing fixed, substations, ship terminals and power cables manufacturing?

Here you’ve come to the right place.

Check out the following buyer’s detailed guide for project engineers, operators and beginners, we’ll offer you the high quality stainless steel banding strapping solutions with 24/7 custom service to fit your every idea and plan.

Contact our HZW team today to get your stainless steel banding buckles and strapping solutions.

What Are Stainless Steel Banding Buckles?

Stainless steel banding buckles are also called stainless steel banding clips.

It is designed for light duty purpose, to be used together with bare stainless steel banding strap or insulated stainless steel banding strap.

Special tensioning tools are also required for installing these banding strap buckles.

The stainless steel buckles are made of 201, 202, 304 and 316L stainless steel materials. It is formed by stamping process.

It has the characteristics of smooth surface, no burr on the edges and corners, rust prevention, corrosion resistance, cold resistance, high temperature resistance, convenient use and large bearing capacity.

The use of temperature range is from 60 °C to 300 °C.

Grade 201 stainless steel banding buckle has superior yield and tensile strength properties to provide maximun clamping strength for different application. Grade 201 stainless steel is a lower-cost alternative to the conventional Cr-Ni austenitic stainless steels, such as 304 steel.

As you know, 201 vickers hardness is above 190HV. And 304 or 316 grade hardness is range from 150HV to 180HV.

304 grade is a common material in stainless steel area, with a density of 7.93 g/cm³, which is also called 18/8 stainless steel in the industry. GB standard is 0Cr18Ni9.

Grade 304 stainless steel banding buckles are most common used and can be applied in almost any environment.

Grade 316 stainless steel banding strap buckles are specialized for seaside cities or extreme corrosive enviroment, such as the chemical factory or oil field application.

Contains aluminum, so the resistance to pitting corrosion in marine and chemical industrial environments is much better than 304 stainless steel.

316L stainless steel is almost identical to 316 grade.

316L stainless steel has lower carbon content imparts even better corrosion resistance than 316.

Stainless steel buckles products are widely used in municipal construction, signs, electrical boxes, cameras, lights, high voltage cable, tubing fixed, substations, ship terminals, and other industries.

Types of Stainless Steel Banding Buckles

1.Ear-Lokt Stainless Steel Banding Buckles

The stainless steel ear-lokt banding buckles are also called stainless steel teeth buckles.

It is designed for light duty purpose, to be used together with bare stainless steel banding strap or insulated stainless steel banding strap.

Stainless steel ear-lokt banding buckles are widely used in municipal construction, signs, electrical boxes, cameras, lights, high voltage cable, tubing fixed, substations, ship terminals, and other industries.

2.Stainless Steel Screw Buckles

Stainless steel screw buckles can be used with different width of stainless steel band/strap for providing fastening strength.

201/304/316 stainless steel material offers good resistance to oxidation and many moderate corrosive agents.

Stainless steel screw buckle is manufactured from prime quality ASTM 201, 304, 316 stainless steel material.

The stainless steel screw buckle is used with stainless steel band strap to create reusable ties of different length.

The core feature of the stainless steel screw buckle is itself strength. This feature is due to the single stainless steel pressing design which allows for construction without joins or seams.

The stainless steel screw buckle is available in matching 1/4”, 3/8”, 1/2”, 5/8” and 3/4” inch width.

Grade 316 stainless steel screw buckle for seaside application.The 316 stainless steel screw buckle is manufactured from prime quality type 316 stainless steel suitable for application in highly corrosive and marine special environments.

3.Stainless Steel Wing Seals

Stainless steel wing seal is also called stainless steel clip or banding clip.

It is designed for light duty purpose, to be used together with bare stainless steel banding strap or insulated stainless steel banding strap. Special tensioning tools are also required for installing these banding strap and wing seals.

The high strength of the stainless steel wing seal is widely used in various areas (petrochemical, bridges construction, tower, oil and gas pipelines, cable tray system, traffic facilities, outdoor billboards, electric power facilities, etc.).

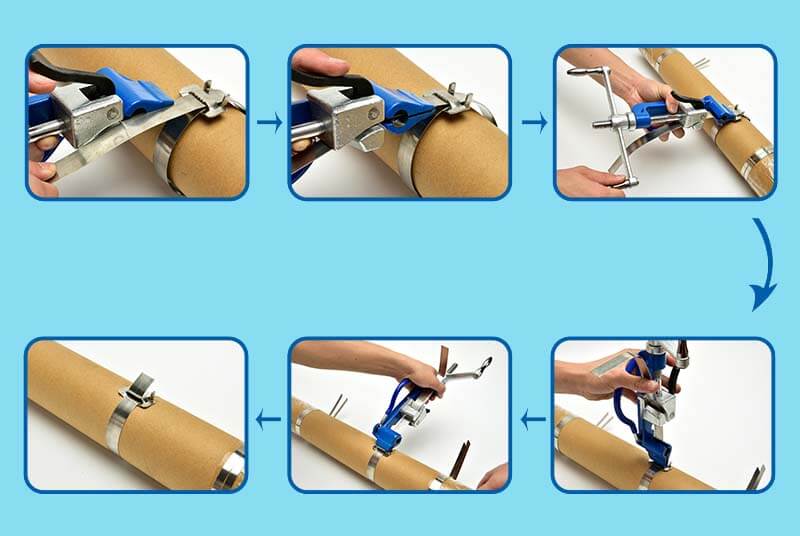

How Are Stainless Steel Banding Buckles Used?

Step 1

The stainless steel banding strapping passes directly through the banding buckle.

Step 2

Bend the stainless steel banding strapping, and then clamp the buckles with bands.

Step 3

Let the another side banding strapping pass through the stainless steel banding buckles.

Step 4

Will tie tail into the banding tools openings and banding strap into the taut block card slot

Step 5

Cable tie is taut, push pressure on the clamp

Step 6

Left hand grasp banding tool, right hand pull cutting knife, will finish stainless steel banding strap cut off

Step 7

This is the last step.

Use pliers to bend the edge of the stainless steel banding buckles, and then use a hammer to hit the tie to make it fit only with the stainless steel banding strapping.

Check out the following video guide for project engineers, operators and beginners, you will know more about how to cut stainless steel banding strapping clearly.

What Is The Packaging Standard of Stainless Steel Banding Buckles?

HZW has professional packaging team who can adopt developed packaging technology and packaging style to ensure every stainless steel banding strapping buckle packaging quality.

- Standard sea packaging, the stainless steel banding strapping buckle can be packaged by wooden case and carton box.

- Stainless steel banding strapping buckle surface is protected by plastic bag and good quality carton box.

- In addition, clear labels are tagged on the outside of the packages for easy identification of the stainless steel banding strapping buckle measurements and quality information.

How To Buy Stainless Steel Banding Buckles?

For example, when you want to purchase high quality stainless steel strapping buckle products here, the following information should be clarified before placing order:

- Grades: 304

- Types: Wing Seals

- Standards: ASTM/JIS/EN

- Specifications: Thickness, Width,Tolerance

- Requirement On Properties: Hardness Range, Yield Strength, Tension Strength, Elongation, Round Edge, etc.

- Surface Finish: 2B, BA, Polishing Bright, etc.

- Packaging Requirement: Good quality plastic box and carton box packaging

- Delivery Time: 15-20 Working days after confirmed the deposit

- Quoted Term: EXW, FCA, FOB, CFR, CIF, DDP, etc