Nickel Alloy 825 Strip

Nickel Alloy 825 Strip/Incoloy 825 Strip

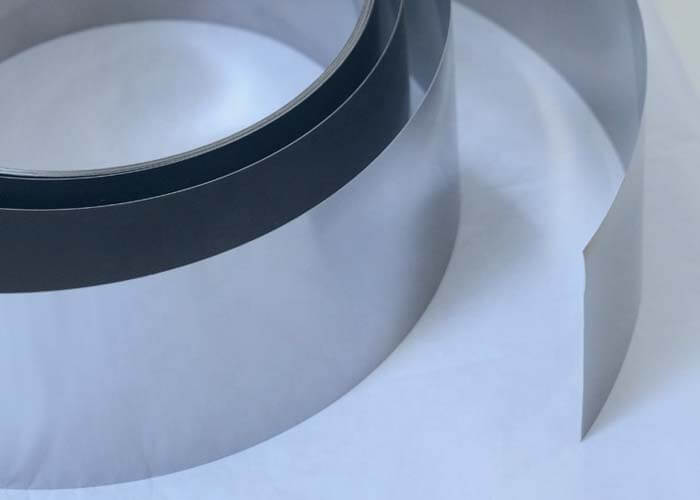

Nickel alloy 825 strip is known as Incoloy UNS N08825 WNR 2.4858 strip. It is nickel-iron-chromium alloy strip with additions of molybdenum, copper and titanium.

This nickel steel alloys chemical composition is designed to provide exceptional resistance to many corrosive environments. It is similar to alloy 800 strip but has improved resistance to aqueous corrosion.

It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion.

Nickel Alloy 825 Strip Specifications

| Product Name | Nickel Alloy 825 Strip | Incoloy UNS N08825 Alloy Strip |

| Grades | Alloy 825 |

| Hardness | 126 Brinell or as request |

| Thickness | 0.02mm-3.0mm |

| Width | 1.0mm-600mm |

| Edge | Slit/Deburred/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 200mm,Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on customer request |

| Surface Finish | The alloy 825 strip has a smooth surface, free from scratches and impurities |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 15-20 working days |

| MOQ | 2 Tons |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of nickel alloy 825 strip is available |

| Remark | Nickel alloy 825 strip can be customized |

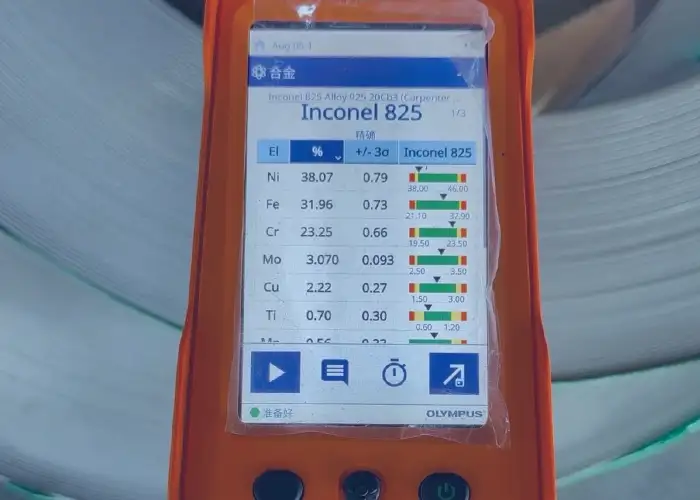

Nickel Alloy 825 Strip Chemical Compositions

| Nickel 825 Alloy Strip Chemical Composition(%) | ||||||||||

| Ni | Fe | Cr | Mo | Cu | Ti | C | Mn | S | Si | Al |

| 38.0-46.0 | 22.0 min | 19.5-23.5 | 2.5-3.5 | 1.5-3.0 | 0.6-1.2 | 0.05 max | 1.0 max | 0.03 max | 0.5 max | 0.2 max |

From this picture, you can see how to deal with Incoloy 825 alloy strip positive material identification test in our company. The strict control and management to ensure each nickel alloy 825 strip has right chemical contents.

Nickel Alloy 825 Strip Mechanical Properties

| Element | Yield Strength (0.2%Offset) | Melting Point | Density | Tensile Strength | Elongation |

| Incoloy® 825 | Min Psi – 35,000 , MPa – 241 | 1400 °C (2550 °F) | 8.14 g/cm3 | Min Psi – 85,000 , MPa – 586 | Min 30 % |

Nickel Alloy 825 Strip Standards Comparison Table

| STANDARD | Incoloy® 825 |

| WERKSTOFF NR. | 2.4858 |

| UNS | N08825 |

How Nickel Alloy 825 Strips Are Made?

- Raw Material Selection

- Melting and Alloying

Casting - Hot Rolling

- Cold Rolling

- Annealing

- Finishing

- Slitting

- Quality Control and Testing

Nickel Alloy 825 Strips Applications

- Welded tubes and systems

- Chemical processing

- Pollution control

- Oil and gas recovery

- Acid production and pickling operations

- Nuclear fuel reprocessing and handling of radioactive wastes

Nickel Alloy 825 Strips Packaging

- Standard export sea packaging:

Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case; - Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

- Other special packaging will be designed as customer’s request;

Eye to wall and eye to sky are both available; - By International Express: DHL/UPS/FEDEX/EMS and our own express line;

- By air or By sea;

- Shipping port: Shanghai, Ningbo or as your request.