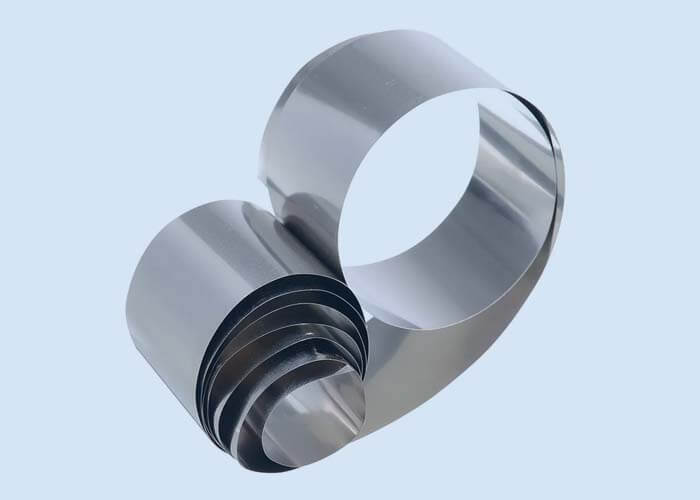

Hastelloy® C-276 Alloy Strip Foil Supplier in China

Hastelloy® C-276 Alloy Strip Foil Quick Details

Hastelloy® C-276 strip foil is a high performance nickel-molybdenum-chromium corrosion resistant nickel based alloy foil material. The C-276 strip foil is supplied according to ASTM B575 standard.

The chromium content ensures the oxidation resistance of the alloy. The molybdenum content ensures the reduction resistance of the alloy.

Hastelloy® C-276 alloy strip foil is widely used in many industrial and commercial applications.

Hastelloy® C-276 Alloy Strip Foil Specifications

| Product Name | Hastelloy® C-276 Alloy Strip Foil |

| Grades | Hastelloy® C-276 |

| Hardness | 70-90HRB |

| Thickness | 0.10mm-3.0mm |

| Width | 1.0mm-600mm |

| Edge | Slit/Deburred/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 200mm, Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on customer request |

| Surface Finish | The alloy C-276 strip foil has a smooth surface, free from scratches and impurities |

| Applications | Pressure Vessels Reactors Mixers and Agitators Scrubbers Dampers Heat Exchangers Evaporators Solvent Recovery Plants Pumps and Valves |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 15-20 working days |

| MOQ | 500 kgs |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of nickel alloy C-276 strip foil is available |

| Remark | Nickel alloy C-276 strip foil can be customized |

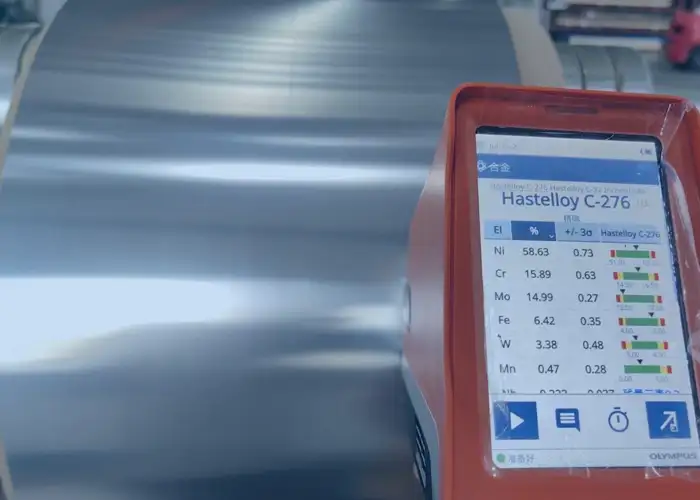

Hastelloy® C-276 Alloy Strip Foil Chemical Compositions

The chemical components of grade Hastelloy® C-276 is summarized in the following table:

| % | Ni | Cr | Mo | W | Co | C | Mn | Si | P | S | Fe | V |

| Min | Balance | 14.5 | 15 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 0 |

| Max | Balance | 16.5 | 17 | 4.5 | 2.5 | 0.01 | 1 | 0.08 | 0.04 | 0.03 | 7 | 0.35 |

From this picture, you can see how to deal with Hastelloy C-276 alloy foil positive material identification test in our company. The strict control and management to ensure each C-276 alloy foil has right chemical contents.

Hastelloy® C-276 Alloy Strip Foil Mechanical Properties

| Element | Yield Strength (0.2%Offset) | Melting Point | Density | Tensile Strength | Elongation |

| Hastelloy® C-276 | Psi – 52,000 , MPa – 355 | 1370 °C (2500 °F) | 8.89 g/cm3 | Psi – 1,15,000 , MPa – 790 | 40 % |

Hastelloy® C-276 Alloy Strip Foil Standards Comparison Table

| STANDARD | Hastelloy® C-276 |

| WERKSTOFF NR. | 2.4819 |

| UNS | N10276 |

How About Hastelloy® C-276 Alloy Strip Foil Production Process?

- Raw Material Selection: The first step is to carefully select the appropriate raw materials for producing Hastelloy® C-276 alloy. The alloy composition typically consists of nickel, molybdenum, chromium, and small amounts of other elements like iron, tungsten, and cobalt.

- Melting and Alloying: The selected raw materials are then melted together in a controlled environment, such as an electric arc furnace or a vacuum induction furnace. This melting process ensures thorough alloying of the components to achieve the desired composition of Hastelloy® C-276.

- Casting: Once the molten alloy is properly alloyed, it is cast into a desired shape, such as large ingots or billets. The casting process helps to solidify the alloy in a form that can be further processed.

- Hot Rolling: The cast ingots or billets are reheated and passed through a series of hot rolling mills. The hot rolling process reduces the thickness of the material and increases its length and width to produce a strip with the desired dimensions. The rolling process may involve multiple passes to achieve the desired thickness and uniformity.

- Cold Rolling: After hot rolling, the strip may undergo additional cold rolling processes to further refine its thickness, improve its surface finish, and enhance its mechanical properties. Cold rolling involves passing the strip through a set of rollers at room temperature, gradually reducing its thickness while maintaining its shape and dimensions.

- Annealing: The cold-rolled strip is then subjected to an annealing process, which involves heating the material to a specific temperature and holding it there for a controlled period. Annealing helps relieve internal stresses and promotes grain growth, resulting in improved ductility and desired mechanical properties.

- Finishing: The annealed strip may undergo additional processes such as surface cleaning, leveling, and slitting to achieve the final dimensions, smoothness, and flatness required for the specific application.

- Quality Control and Testing: Throughout the production process, various quality control measures are implemented to ensure that the Hastelloy® C-276 alloy strip foil meets the required specifications. Testing methods such as chemical analysis, mechanical property evaluation, and non-destructive testing may be employed to verify the quality and performance of the material.

Hastelloy® C-276 Alloy Strip Foil: The Ultimate Guide

When you choose to buy quality Hastelloy® C-276 alloy strip coil, there have some important points we need to know before we get started.

What are Hastelloy® C-276 alloy strip foils?

Hastelloy® C-276 alloy strip foil is a nickel-molybdenum-chromium wrought alloy material. It is also called UNS N10276 strip foil.

The alloy is resistant to pitting, crevice corrosion, and stress corrosion cracking.

Hastelloy® C-276 strips foils are produced strictly to the default ASTM B575 standard.

Hastelloy® C-276 foil strip is commonly used for pollution control equipment because of its excellent resistance to atmospheric corrosion.

HASTELLOY® is a registered trademark of Haynes International Inc.

Hastelloy® C-276 alloy strip foils applications

Hastelloy® C-276 alloy strip foil is commonly used for the following applications:

- Chemical process industry

- Flue gas desulfurization units

- Pickling equipment in the steel industry

- Waste incineration plants

- Seawater desalination plants

- Flue gas scrubbing facilities

- Pharmaceuticals

- Heat exchangers

What are Hastelloy® C-276 alloy strip foil edges?

Different edges will be used for different applications. We can help end users deal with below edges types:

1.Slit

2.Deburred

3.Round

Hastelloy® C-276 alloy strip foil features

High corrosion resistance in a wide range of media.

Excellent resistance in oxidising aqueous media.

High resistance to intergranular corrosion.

Good weldability compared to other alloys in the same family.

How to buy Hastelloy® C-276 alloy strip foil from China?

Therefore, if you want to buy Hastelloy® C-276 alloy strip foil at lower price with high quality and good service from China suppliers, you need to know how to buy nickel alloy strips from China firstly.

First of all, you should choose a reliable supplier who can provide good quality nickel alloy coils products at competitive prices. Then you can negotiate with them on price and other terms until reaching an agreement.

Secondly, you need to check whether they have advanced production equipment or not because if they do not have advanced equipment for producing various kinds of coils including nickel alloy coils or if their production capacity is limited then it would be difficult for them to supply high quality products at competitive prices all year round.

Thirdly, it is better to visit their factory by yourself and check the production line and warehouse by yourself. It will be great if you can check their production process and production equipment. Because it is very important for you to know how they control the quality from process till delivery.

What is the standard sea packaging of Hastelloy® C-276 alloy strip foil?

- Standard export sea packaging:

Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case; - Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

- Other special packaging will be designed as customer’s request;

Eye to wall and eye to sky are both available; - By International Express: DHL/UPS/FEDEX/EMS and our own express line;

- By air or By sea;

- Shipping port: Shanghai, Ningbo or as your request.

Additional Information on Hastelloy® C-276 alloy strip foil

Hastelloy C-276 is a very commonly used nickel-chromium-molybdenum alloy. Among superalloys, it is known for its high molybdenum content.

First, as a corrosion-resistant element, molybdenum brings very high resistance to reductive corrosion to the alloy. By combining with nickel and chromium, Hastelloy C-276 has very good overall corrosion resistance. Compared with stainless steel, its excellent resistance to stress corrosion cracking in chloride-containing solutions cannot be replaced.

Secondly, the solid solution strengthening effect of molybdenum and tungsten elements is very obvious, and they bring very high strength to Hastelloy C-276 alloy. Like other nickel alloys, Hastelloy C-276 has good ductility. It is easy to shape and weld.

Hastelloy C-276 alloy is well suited for gas melting arc (GMA/MIG), gas tungsten arc (GTA/TIG) and shielded metal arc (SMA/Stick) welding processes. Hastelloy C-276 is ideal for marine applications. Its corrosion resistance makes it resistant to various corrosive substances in flowing seawater for a long time. However, Hastelloy C-276 also has good overall performance at high temperatures. It is very suitable for the preparation equipment of various corrosive chemicals or the reactor of various acidic substances.

Additionally, Hastelloy C-276 has demonstrated exceptional ability to resist seawater corrosion. Sea water is the most common salt water solution. It is widely used in marine and offshore oil rigs and as a coolant in coastal installations.

Finally, although the microstructural inhomogeneity of the weld may result in slightly higher corrosion rates (relative to a uniformly forged product), Hastelloy C-276 is still able to resist corrosion in the weld area and exhibit excellent performance.

Hastelloy C-276 is a solid solution alloy. This alloy has good solid solution strengthening effect. Hastelloy C-276 is stronger than stainless steel, and even stronger than most solid solution alloys. Therefore, it is also easier to increase strength through cold working.

Note, however, that cold working will generally affect the resistance of Hastelloy C-276 to stress corrosion cracking. Proper annealing is very important for cold worked parts in order to achieve optimum corrosion performance. The corrosion resistance and ductility of this alloy can be improved by proper annealing process. In addition, for Hastelloy C-276, it is recommended to use a faster cooling rate for annealing.