Incoloy 825

Introduction

Overview of Incoloy 825 Alloy

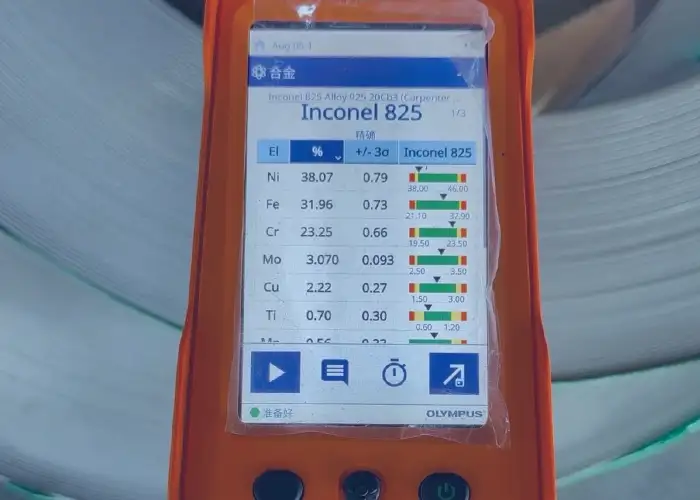

Incoloy alloy 825 (UNS N08825 / W.Nr. 2.4858) is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium.

The alloy’s chemical composition is designed to provide exceptional resistance to many corrosive environments. The nickel content is sufficient for resistance to chloride-ion stress-corrosion cracking.

The nickel, in conjunction with the molybdenum and copper, also gives outstanding resistance to reducing environments such as those containing sulfuric and phosphoric acids. The molybdenum also aids resistance to pitting and crevice corrosion. The alloy’s chromium content confers resistance to a variety of oxidizing substances such as nitric acid, nitrates and oxidizing salt. The titanium addition serves, with an appropriate heat treatment, to stabilize the alloy against sensitization to intergranular corrosion.

The resistance of Incoloy alloy 825 to general and localized corrosion under diverse conditions gives the alloy broad usefulness. Applications include chemical processing, pollution control, oil and gas recovery, acid production, pickling operations, nuclear fuel reprocessing, and handling of radioactive wastes.

Corrosion Resistance of Incoloy 825

The outstanding attribute of Incoloy alloy 825 is its high level of corrosion resistance. In both reducing and oxidize environments, the alloy resists general corrosion, pitting, crevice corrosion, intergranular corrosion, and stress-corrosion cracking.

Some environments in which Incoloy alloy 825 is particularly useful are sulfuric acid, phosphoric acid, sulfurcontaining flue gases, sour gas and oil wells, and sea water.

Incoloy 825 Alloy Applications

Incoloy 825 alloy can be used in a variety of applications including:

- Fuel element dissolvers

- Sea-water-cooled heat exchangers; offshore product piping systems; tubes and components in sour gas service

- Heat exchangers, evaporators, scrubbers, dip pipes etc.

- Air-cooled heat exchangers in petroleum refineries

- Chemical Processing

- Food Processing

Incoloy 825 Tags

- UNS Number: N08825

- Werkstoff Number: 2.4858

- Standards: ASTM B163, B423, B424, B425, B564, B704, B705, B366, B751, B775, B829

Incoloy 825 Quality Products

Incoloy 825 Technical Data

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Alloy 825 | 2.4858 | N08825 | – | – | – | – | – | – |

| 825 Alloy Chemical Composition(%) | ||||||||||

| Ni | Fe | Cr | Mo | Cu | Ti | C | Mn | S | Si | Al |

| 38.0-46.0 | 22.0 min | 19.5-23.5 | 2.5-3.5 | 1.5-3.0 | 0.6-1.2 | 0.05 max | 1.0 max | 0.03 max | 0.5 max | 0.2 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.14 g/cm3 | 1400 °C (2550 °F) | 690-1000Mpa | 330-880Mpa | 45% – 15% |

Related Resources

What is Incoloy 825 Alloy?

INCOLOY® alloy 825 (UNS N08825 / W.Nr. 2.4858) is a nickel-iron-chromium alloy enriched with molybdenum, copper, and titanium. The alloy’s chemical composition is meticulously formulated to impart exceptional resistance to a wide range of corrosive environments. Adequate nickel content ensures resilience against chloride-ion stress-corrosion cracking. The synergy of nickel, molybdenum, and copper imparts remarkable resistance

Incoloy Alloys: A Comprehensive Guide

Incoloy alloys are known for their iron content. Nickel, iron, and chromium are the main and vital ingredients for Incoloy alloys. Incoloy alloys have more iron contents than inconel alloys. These alloys show outstanding corrosion resistance, strength, durability, and high-temperature stability. Nickel is an essential metal that is in limited availability for the development of

Difference Between Inconel 625 Strip and Incoloy 825 Strip

The article discusses the difference between two nickel-based alloy strips, Inconel 625 strip and Incoloy 825 strip. Both alloys are designed to provide exceptional resistance to many corrosive environments. However, there are distinct differences between the two. Incoloy 825 contains a higher chromium content, whereas Inconel 625 strip has a higher molybdenum content, leading to

Difference Between Incoloy 800 Strip and Incoloy 825 Strip

Adding molybdenum and copper in Incoloy 800 strips makes a super alloy called Incoloy 825. The Incoloy 825 strip is more corrosion-resistant than Incoloy 800 strip. The Incoloy 800 strips have nickel, iron, and chromium in composition, and the Incoloy 825 strips have molybdenum and copper, along with nickel, iron, and chromium. The density of