Inconel 625 Alloy Strip

Inconel 625 Alloy Strip Quick Details

Inconel 625 alloy strip is a nickel alloy strip with excellent oxidation resistance, corrosion resistance, and strength at high temperatures.

It is widely used in the aerospace, oil and gas, automotive, marine, chemical processing and nuclear industries.

Service temperatures range from cryogenic to 1800°F (982°C).

Inconel 625 Alloy Strip Specifications

| Product Name | Inconel 625 Alloy Strip |

| Grades | INCONEL® alloy 625 (UNS N06625/W.Nr. 2.4856) |

| Hardness | Soft tempered or as customers’ requests |

| Thickness | 0.1mm-4.0mm |

| Width | 6.0mm-350mm |

| Edge | Slit/Mill/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø500mm paper core, special internal diameter core and without paper core on customer request |

| Surface Finish | NO.1/2B/2D/BA/HL/Brushed, etc. |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 25-30 working days |

| MOQ | 500Kgs |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The inconel 625 strip sample is available |

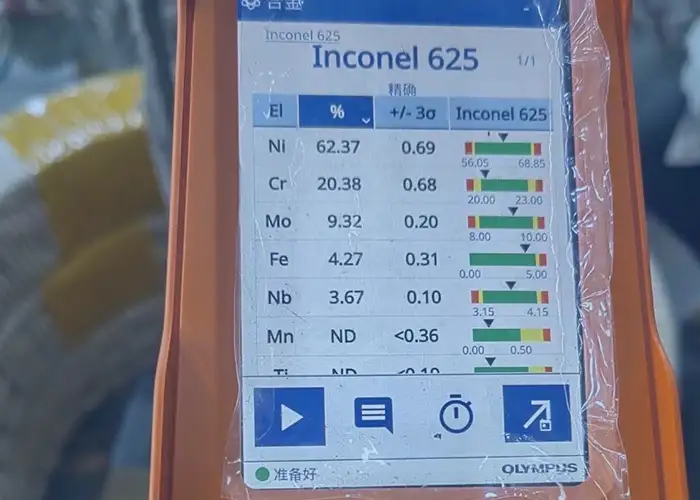

Inconel 625 Alloy Strip Chemical Compositions

The chemical components of grade Inconel 625 strip is summarized in the following table:

| Grade | Standard | C | Si | Mn | P | S | Cr | Ni | Mo |

| Inconel 625 | ASTM B 443/AMS 5599 | ≤0.1 | ≤0.50 | ≤0.50 | ≤0.015 | ≤0.015 | 20.00-23.00 | ≥58.0 | 8.0-10.0 |

From this picture, you can see how to deal with Inconel 625 alloy strip positive material identification test in our company. The strict control and management to ensure each nickel alloy 625 strip has right chemical contents.

Inconel 625 Alloy Strip Mechanical Properties

| Element | Yield Strength (0.2%Offset) | Melting Point | Density | Tensile Strength | Elongation |

| Inconel® 625 | Min Psi – 60,000 , MPa – 414 | 1350 °C (2460 °F) | 8.4 g/cm3 | Min Psi – 120,000 , MPa – 827 | Min 30 % |

Inconel 625 Alloy Strip Standards Comparison Table

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Alloy 625 | 2.4856 | N06625 | ХН75МБТЮ | NC22DNB4M | NCF 625 | NA 21 | NiCr22Mo9Nb | ЭИ602 |

How About Inconel 625 Alloy Strip Production Process?

Inconel 625 strip is a flat rolled alloy product that has been processed through a cold rolling mill to reduce the thickness and increase the strength of the material.

This process is commonly referred to as cold reducing.

Cold reducing is performed at room temperature, whereas hot rolling reduces metal at temperatures above what is considered room temperature.

Cold reducing results in increased strength, improved surface finish and greater uniformity in size.

In addition to manufacturing nickel alloys strip, HZW also offers additional services such as:

- Slitting: We can slit your nickel alloys strip to your desired widths.

- Edging: The edges of your nickel alloys strip can be rolled to prevent sharp edges and for easy handling.

- Oscillate Winding: Oscillate winding allows a coil to be wound using less space than traditional straight line coils, saving you money on shipping costs.

- Sampling: Our cut-to-length service allows us to process your nickel alloys strip into sheets of any size.

Inconel 625 Alloy Strip: The Ultimate Guide

When you choose to buy quality Inconel 625 alloy strip, there have some important points we need to know before we get started.

What are Inconel 625 alloy strips?

Inconel 625 alloy strip is a nickel alloy with excellent oxidation resistance, corrosion resistance, and strength at high temperatures.

It is widely used in the aerospace, oil and gas, automotive, marine, chemical processing and nuclear industries.

Service temperatures range from cryogenic to 1800°F (982°C).

Inconel 625 strips are slitted from mother coils.

At HZW, Our team can help provide round edge Inconel 625 strips to meet your special demands.

Inconel 625 alloy strip applications

- Aerospace

- Automotive

- Marine

- Chemical Processing

- Power Generation

- Nuclear

What are Inconel 625 alloy strips edges?

Mill edge is a non-trimmed edge appearance after hot or cold rolling and annealing/pickling process. It usually leaved an irregular pinhole line on the edge side around 10mm to 15mm.

Slit/slitting edge means we will trim irregular pinhole line on our slitting machine.

In addition, our expert team can also provide round edge Inconel 625 strips to meet your project needs.

How to buy Inconel 625 alloy strip from China?

Therefore, if you want to buy Inconel 625 alloy Strip at lower price with high quality and good service from China suppliers, you need to know how to buy nickel alloy strips from China firstly.

First of all, you should choose a reliable supplier who can provide good quality Inconel 625 alloy coils products at competitive prices. Then you can negotiate with them on price and other terms until reaching an agreement.

Secondly, you need to check whether they have advanced production equipment or not because if they do not have advanced equipment for producing various kinds of coils including nickel alloys coils or if their production capacity is limited then it would be difficult for them to supply high quality products at competitive prices all year round.

Thirdly, it is better to visit their factory by yourself and check the production line and warehouse by yourself. It will be great if you can check their production process and production equipment. Because it is very important for you to know how they control the quality from process till delivery.

What is the standard sea packaging of Inconel 625 alloy strip?

- Standard export sea packaging:

Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case; - Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

- Other special packaging will be designed as customer’s request;

Eye to wall and eye to sky are both available; - By International Express: DHL/UPS/FEDEX/EMS and our own express line;

- By air or By sea;

- Shipping port: Shanghai, Ningbo or as your request.