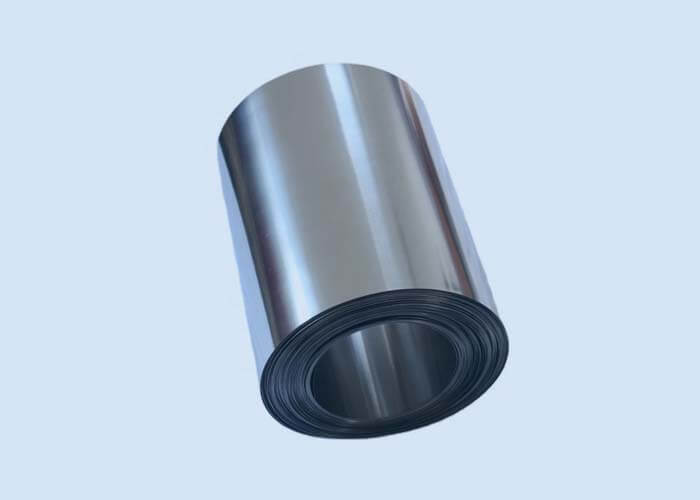

Nickel Alloy 625 Strip

Nickel Alloy 625 Strip/Inconel 625 Strip

Nickel alloy 625 strip is one of the most versatile nickel alloys on the market. When it comes to corrosion resistance, strength, and fabricability, nickel alloy 625 strip is one of the best options for your application.

As a leading supplier of nickel alloys strips produced by many mills, HZW can offer you precision alloy 625 strips materials in widths ranging from 2mm to 600mm and thicknesses ranging from 0.02mm to 3mm.

Nickel Alloy 625 Strip Specifications

| Product Name | Nickel Alloy 625 Strip | Inconel UNS N06625 Alloy Strip |

| Grades | Alloy 625 |

| Hardness | 70-90HRB |

| Thickness | 0.02mm-3.0mm |

| Width | 1.0mm-600mm |

| Edge | Slit/Deburred/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 200mm,Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on customer request |

| Surface Finish | The alloy 625 strip has a smooth surface, free from scratches and impurities |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 15-20 working days |

| MOQ | 2 Tons |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of nickel alloy 625 strip is available |

| Remark | Nickel alloy 625 strip can be customized |

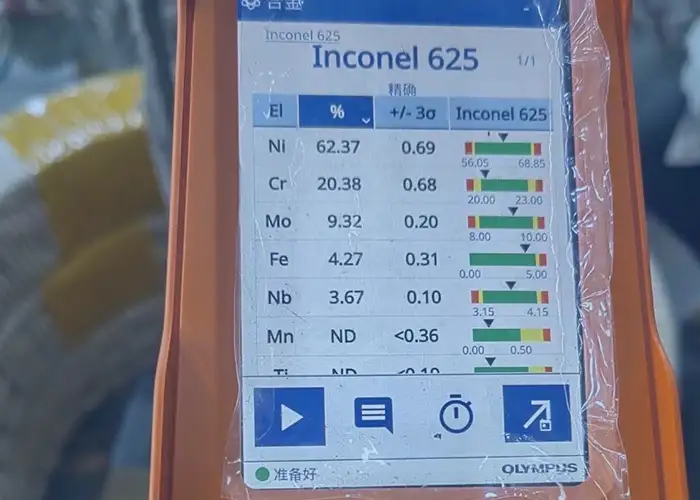

Nickel Alloy 625 Strip Chemical Compositions

From this picture, you can see how to deal with Inconel 625 alloy strip positive material identification test in our company. The strict control and management to ensure each nickel alloy 625 strip has right chemical contents.

| Nickel 625 Alloy Strip Chemical Composition(%) | ||

| Element | Min | Max |

| C | – | 0.1 |

| Si | – | 0.5 |

| Mn | – | 0.5 |

| P | – | 0.015 |

| S | – | 0.015 |

| Al | – | 0.4 |

| Cr | 20 | 23 |

| Cu | 1 | 1.4 |

| Fe | – | 5 |

| Mo | 8 | 10 |

| Nb | 3.15 | 4.15 |

| Ni | Min 58.0 | |

| Ti | – | 0.4 |

Nickel Alloy 625 Strip Mechanical Properties

| Element | Yield Strength (0.2%Offset) | Melting Point | Density | Tensile Strength | Elongation |

| Inconel® 625 | Min Psi – 60,000 , MPa – 414 | 1350 °C (2460 °F) | 8.4 g/cm3 | Min Psi – 120,000 , MPa – 827 | Min 30 % |

Nickel Alloy 625 Strip Standards Comparison Table

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Alloy 625 | 2.4856 | N06625 | ХН75МБТЮ | NC22DNB4M | NCF 625 | NA 21 | NiCr22Mo9Nb | ЭИ602 |

How Nickel Alloy 625 Strips Are Made?

The production process of nickel alloy 625 strip is as follows:

1. Nickel Alloy 625 coil preparation

2. Nickel Alloy 625 wide coil cold rolling

3. Nickel Alloy 625 coil leveling & straightening

4. Nickel Alloy 625 strip annealing & cleaning

5. Nickel Alloy 625 strip slitting & cutting

5. Nickel Alloy 625 strip packaging & storage

Nickel Alloy 625 Strips Applications

- Aerospace

- Automotive

- Marine

- Chemical Processing

- Power Generation

- Nuclear

Inconel Alloy 625 Strips Packaging

- Standard export sea packaging:

Waterproof Paper Winding+PVC Film+Strap Banding+Wooden Pallet or Wooden Case; - Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

- Other special packaging will be designed as customer’s request;

Eye to wall and eye to sky are both available; - By International Express: DHL/UPS/FEDEX/EMS and our own express line;

- By air or By sea;

- Shipping port: Shanghai, Ningbo or as your request.

What is Inconel 625 alloy strip?

Do you know what is Inconel 625 alloy strip?

Inconel 625 is also called UNS N06625 or W.Nr. 2.4856 alloy. It is a solid solution alloy with high strength and excellent corrosion resistance.

Inconel 625 strip adds molybdenum and niobium elements to Inconel 600 strip. Both of these elements are excellent solid solution strengthening elements.

They give Inconel 625 strip higher strength than similar alloys. In addition, molybdenum is very resistant to reductive corrosion. It also gives the alloy better resistance to severe corrosion.

Due to its excellent corrosion resistance, a typical application of Inconel 625 strip is marine. Its resistance to localized corrosion (pitting and crevice corrosion), chloride ion stress corrosion, and its excellent fatigue strength make it widely used in marine parts such as welding pipes, exhaust pipes and systems. For ambient temperature applications, Inconel 625 strip is recommended to be delivered annealed.