The stainless steel tubes and pipes are good materials due to its high strength, corrosion resistance, and ease of welding and fabrication.

Due to its high strength, stainless steel tubes and pipes are widely used in the manufacturing and industry fields.

When considering the dimensions of stainless steel tubes and pipes, you’ve arrived at the appropriate place.

If you want to learn more about the stainless steel tubes and pipes sizes, this article is very helpful for you.

Let’s keep reading.

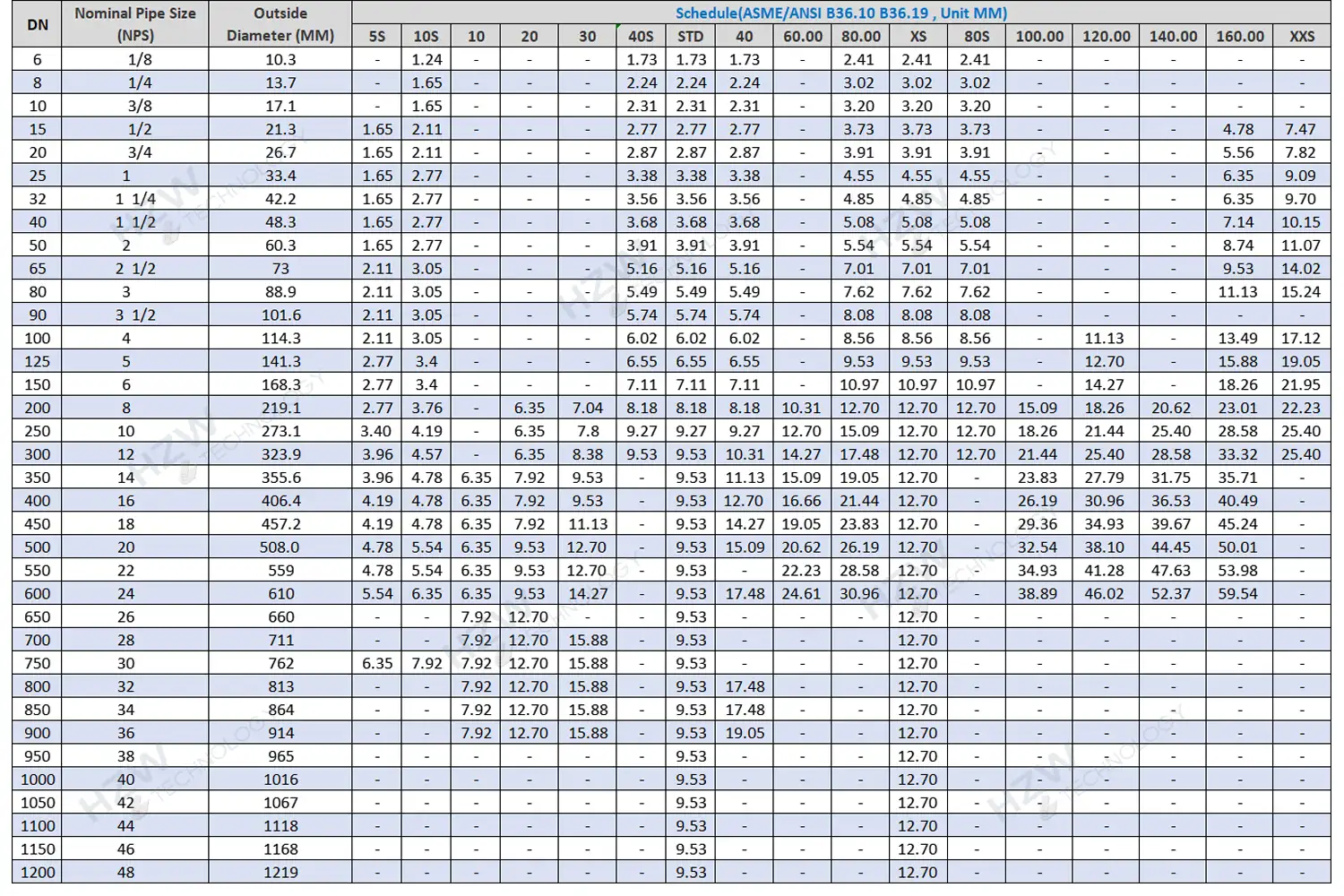

Stainless Steel Tubes and Pipes Sizes Chart:

Characteristics of Stainless Steel Tubes and Pipes

Stainless steel tube and pipe is commonly specified based on parameters such as OD (outside diameter), WT (wall thickness), grade, condition, and surface finish.

Renowned for its resistance to various forms of corrosion, stainless steel tubing boasts hygienic and sterile properties, coupled with an attractive aesthetic appeal and remarkable strength.

The tubing is crafted in round, square, and rectangular sections, featuring a variety of wall thicknesses. Production methods typically involve longitudinal welding, hot and cold drawing.

Surface finishes vary from unpolished to highly polished. Unpolished surfaces exhibit a 2B mill finish, standard polished finishes boast finely grit-polished surfaces, and a finer buffed finish provides an appearance close to a mirror.

The choice of finishes is made with consideration for the intended application and desired aesthetic qualities.

Stainless Steel Tubes and Pipes Grades

- Austenitic Stainless Steel Tubes and Pipes: 201, 304, 304L, 316L, 317L, 347H, 321, 904L, 316Ti, 309S, 310S, 254SMO, UNS N08367, etc.

- Ferritic Stainless Steel Tubes and Pipes: 409S, 430, 439, 441, 434, 436, 444, 446, etc.

- Martensitic Stainless Steel Tubes and Pipes: 403, 410/410S, 414L, 441, 418, 420, 420J2, 440, 416, etc.

- Duplex & Super Duplex Stainless Steel Tubes and Pipes: S32205, S32750, S32760, etc.

Stainless Steel Tubes and Pipes Specifications

- A213 – Seamless Stainless Steel Boiler, Superheater, and Heat-Exchanger Tubes

- A249 – Welded Stainless Steel Boiler, Superheater, Heat Exchanger, and Condenser Tubes

- A268 – Seamless and Welded Stainless Steel Tubing for General Service

- A269 – Seamless and Welded Austenitic Stainless Steel Tubing for General Service

- A270 – Seamless and Welded Stainless Steel Sanitary Tubing

- A688 – Welded Austenitic Stainless Steel Feedwater Heater Tubes

- A789 – Seamless and Welded Stainless Steel Tubing for General Service

How to Choose the right Stainless Steel Tubes and Pipes?

Choosing the right stainless steel tubes and pipes involves considering several key factors to ensure they meet the specific requirements of your intended application. Here are some guidelines to help you make an informed decision:

- Material Grade

- Dimensions

- Application Requirements

- Manufacturing Process

- Surface Finish

- Certifications and Standards

- Corrosion Resistance

- Availability and Cost

- Supplier Reputation

- Testing and Inspection

By carefully considering these factors, you can choose the right stainless steel tubes and pipes that align with the demands of your application, ensuring durability and optimal performance.

Conclusion

Stainless steel tubes and pipes are most widely used in many applications due to their good features and excellent strength.

The stainless steel tubes and pipes sizes plays a vital role in many industries, especially in pipe fittings manufacturing.

At HZW, you have access to premium-quality stainless steel strips and stainless steel foils available in the market. Feel free to consult our experts for your stainless steel welded pipes and tubes projects.