Monel 400

Introduction

Overview of Monel 400 Alloy

Monel alloy 400 (UNS N04400/W.Nr. 2.4360) is a solid-solution alloy that can be hardened only by cold working.

It has high strength and toughness over a wide temperature rangeand excellent resistance to many corrosive environments.

The alloy also has good mechanical properties from sub-zero temperatures up to 549°C.

Alloy 400 is widely used in many fields, especially marine and chemical processing.

Typical applications are valves and pumps; pump and propeller shafts; marine fixtures and fasteners; electrical and electronic components; springs; chemical processing equipment; gasoline and fresh water tanks; crude petroleum stills, process vessels and piping; boiler feedwater heaters andother heat exchangers; and deaerating heaters.

Corrosion Resistance of Monel 400

Monel alloy 400 exhibits resistance to corrosion by many reducing media. It is also generally more resistant to attack by oxidizing media than higher copper alloys. This versatility makes alloy 400 suitable for service in a variety of environments.

Alloy 400 is widely used in marine applications. While alloy 400 products exhibit very low corrosion rates in flowing seawater, stagnant conditions have been shown to induce crevice and pitting corrosion. Alloy 400 is also resistant to stress corrosion cracking and pitting in most fresh and industrial waters.

Monel 400 Alloy Applications

Monel Alloy 400 can be used in a variety of applications including:

- Packed columns

- Pressure vessels and reactors

- Brine heaters

- Heat exchangers

- Salt production equipment

- Pump and valve components

- Pipe work and pipe spools

Monel 400 Tags

- UNS Number: N04400

- Werkstoff Number: 2.4630

- Standards: ASTM B127, B163, B164, B165, B564, B725, B730, B366, AMS 4675, 4730, AMS 4544, 4731

Monel 400 Quality Products

Technical Data

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Alloy 400 | 2.4630 | N04400 | – | – | – | – | – | – |

Grade | % | Ni | Cu | Fe | C | Mn | Si | S |

Alloy 400/UNS N04400 | Min | Bal | 28 | |||||

Max | 34 | 2.5 | 0.3 | 2 | 0.5 | 0.024 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.80 g/cm3 | 1350 °C (2460 °F) | 500-950Mpa | 200-900Mpa | 60% – 2% |

Related Resources

What is the Advantage and Disadvantage of Monel Alloy?

Monel alloy is one of the high-quality nickel-based superalloys. This alloy mainly consists of nickel and copper in its composition with some other elements like magnesium, silicon, carbon and iron. Monel alloys are most widely used due to their outstanding corrosion resistance, strength and high-temperature durability. The first monel alloy was produced commercially in 1905.

Monel Alloys: A Comprehensive Guide

Monel® are alloys that are made mostly from the composition of metals like nickel and copper. Monel alloys also consist of small amounts of silicon, iron, carbon, and manganese. Monel alloys contain less than 60% copper, which means that they are not cupronickel alloys. Monel alloys are generally much more expensive alloys than others, but

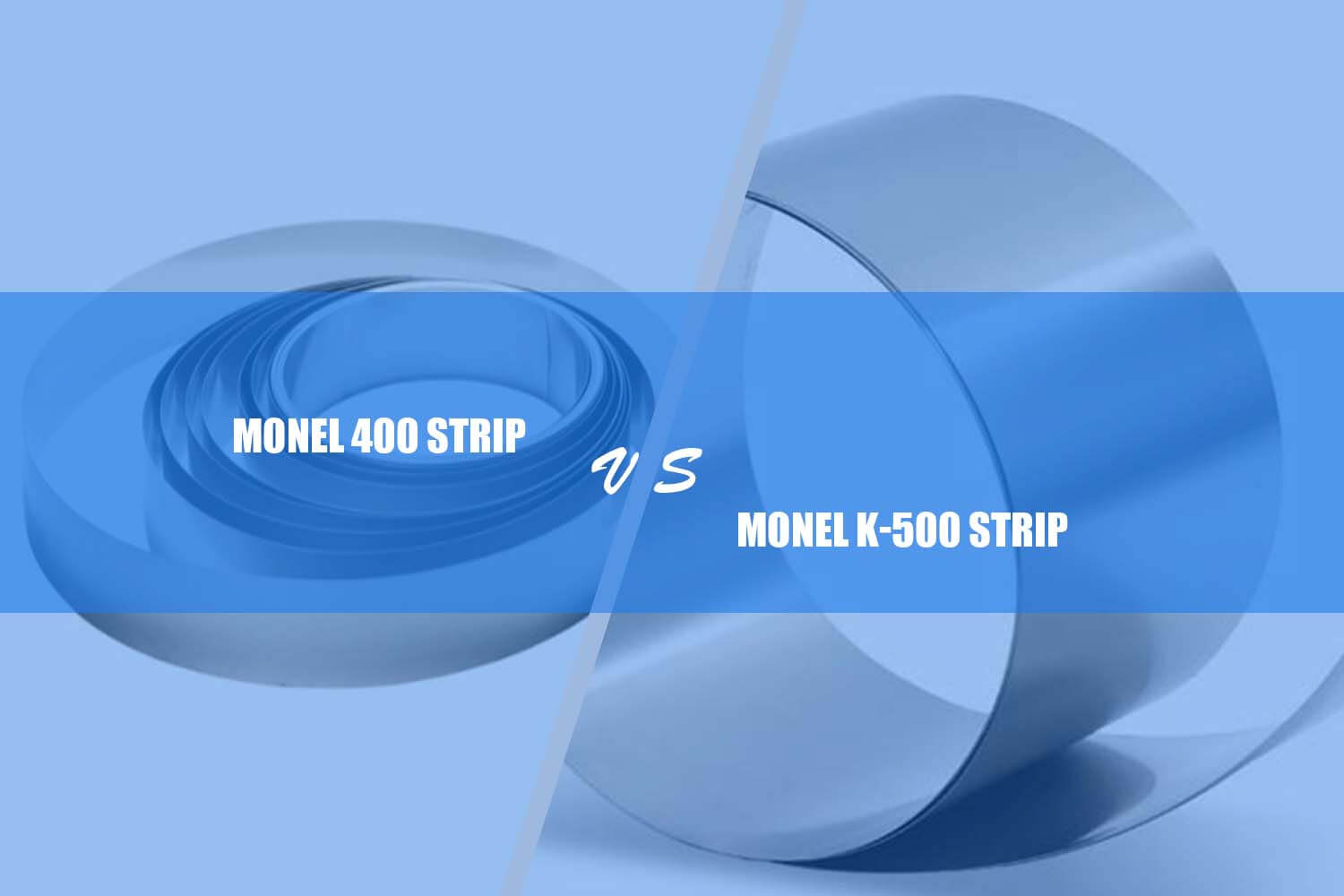

Monel 400 vs. Monel K-500 Strip: Which One is Best for You?

Monel 400 vs. Monel K-500 strip: We mentioned the use of monel in marine environments before, like in high quality welded alloy pipes. But what exactly is monel? How is it different from normal stainless steel strips? Is it good for Heat treating parts making? Well, HZW is here to answer these questions and more! Let’s