Inconel 600 strip and Inconel 601 strip are two frequently used nickel alloys strips. Both alloys have good high temperature properties.

Among them, Inconel 601 added more chromium on the basis of Inconel 600. So their main difference is the difference in antioxidant properties.

Determining the suitable choice for your alloy strip project can be perplexing. This article aims to delineate the disparities between these two nickel-based alloys strips, aiding you in arriving at a well-founded choice.

Let’s keep reading.

What is Inconel 600 Strip?

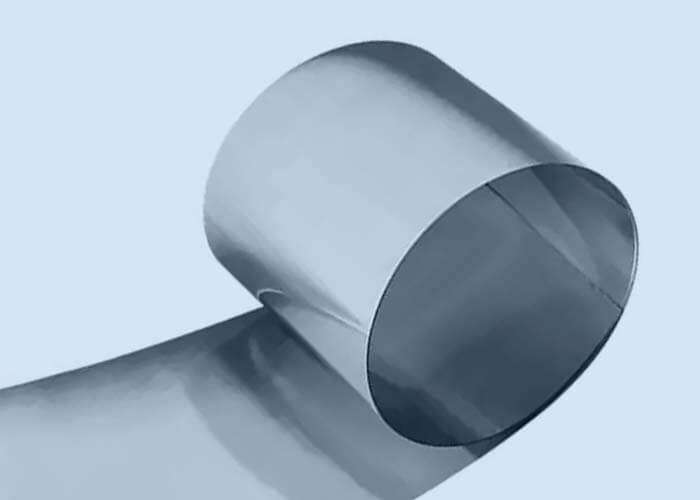

Inconel 600 alloy strip is a standard engineering nickel alloy strip material for applications which require resistance to corrosion and heat.

The alloy strip also has excellent mechanical properties and presents the desirable combination of high strength and good workability.

Inconel 600 strips are slitted from mother coils.

At HZW, Our team can help provide round edge Inconel 600 strips to meet your special demands.

What is Inconel 601 Strip?

Inconel 601 strip is a general-purpose engineering material for applications that require resistance to heat and corrosion.

An outstanding characteristic of Inconel alloy 601 stip is its resistance to hightemperature oxidation.

Difference Between Inconel 600 Strip and Inconel 601 Strip

As you can see from their introduction and products types, Inconel alloy Inconel 600 strip and Inconel 601 strip are very different. Depending on what you are looking for in your project, they each have benefits and drawbacks. For a side by side comparison, you breakdown the differences even further.

Chemical Composition

Inconel 600 Alloy Strip Chemical Composition

The chemical components of grade Inconel 600 strip is summarized in the following table:

| Grade | Standard | C | Si | Mn | P | S | Cr | Ni | Cu |

| Inconel 600 | ASTM B 168/ASME SB 168 | ≤0.15 | ≤0.50 | ≤1.00 | ≤0.015 | ≤0.015 | 14.00-17.00 | ≥72 | ≤0.5 |

Inconel 601 Alloy Strip Chemical Composition

The chemical components of grade Inconel 601 strip is summarized in the following table:

| Grade | Standard | C | Si | Mn | Al | S | Cr | Ni | Cu |

| Inconel 601 | ASTM B 168/ASME SB 168 | ≤0.10 | ≤0.50 | ≤1.00 | 1.00-1.70 | ≤0.015 | 21.00-25.00 | 58.0-63.0 | ≤1.0 |

Corrosion Resistance

As observed in the chemical composition, the nickel content in the Inconel 601 strip is lower than that found in the Inconel 600 strip. In contrast, there is a higher proportion of chromium present, along with the introduction of aluminum elements.

Nickel is recognized for its effective contribution to enhancing the corrosion resistance of alloys. Nevertheless, this corrosion-resistant attribute exhibits limited effectiveness in the face of oxidative environments.

Chromium functions as a potent antioxidant element. When exposed to oxygen, chromium initiates the formation of an oxide film on the metal surface. This oxide film acts as a barrier, impeding further oxidation of the alloy. This explains the widespread incorporation of chromium in nearly all superalloys.

The significant quantity of chromium present in Inconel 601 ensures that its oxidation resistance, particularly at elevated temperatures, surpasses that of Inconel 600.

The inclusion of aluminum elements also serves to heighten the alloy’s oxidation resistance.

Mechanical Properties

Inconel Alloy 600 Strip Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| Inconel 600 | 500 | 180 | 30 | – | – |

Inconel Alloy 601 Strip Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| Inconel 601 | 585 | 205 | 35 | – | – |

Applications

Inconel Alloy 600 Strip Applications

- Retorts

- Muffles

- Roller hearths

- Furnace components

- Heat-treating applications

Inconel Alloy 601 Strip Applications

- Automotive Industry

- Chemical Processing

- Electrical Resistance

- Thermal Processing

- Welding Products

Standards

Inconel Alloy 600 Strips Standards

Strip&Foil: ASTM B168, ASTM B906

Inconel Alloy 601 Strips Standards

Strip&Foil: ASTM B168, ASTM B906

Conclusion

In terms of antioxidation characteristics, Inconel 601 strip surpasses Inconel 600 strip. Apart from this aspect, the two alloy strips do not exhibit further distinctions.

Inconel 600 strip finds itself employed across a broader array of applications, rendering it more prevalent.

We specialize in the production of premium-grade Inconel 600 strip and Inconel 601 strip products. Should a requirement arise, please feel free to reach out to us without hesitation.