Both Inconel 600 strip and Inconel 625 strip are solid solution strengthened Inconel alloys strips.

Due to some chemical composition differences, these two alloys strips have different corrosion resistance and strength.

Determining the suitable choice for your alloy strip project can be perplexing. This article aims to delineate the disparities between these two nickel-based alloys strips, aiding you in arriving at a well-founded choice.

Let’s keep reading.

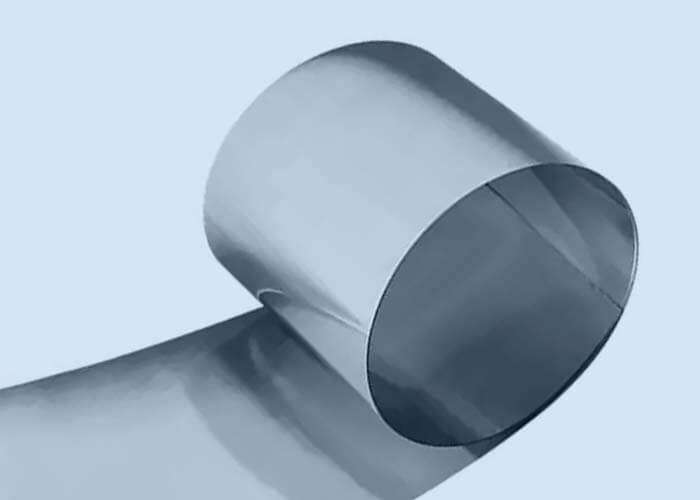

What is Inconel 600 Strip?

Inconel 600 alloy strip is a standard engineering nickel alloy strip material for applications which require resistance to corrosion and heat.

The alloy strip also has excellent mechanical properties and presents the desirable combination of high strength and good workability.

Inconel 600 strips are slitted from mother coils.

At HZW, Our team can help provide round edge Inconel 600 strips to meet your special demands.

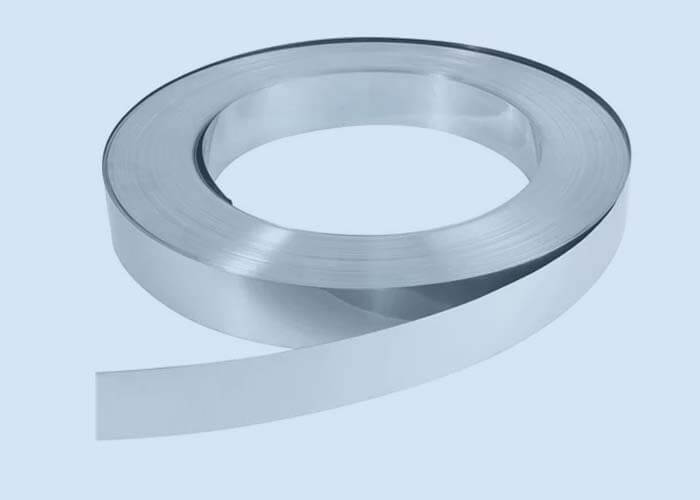

What Is Inconel 625 Strip?

Inconel alloy 625 strip is one of the most versatile nickel alloys on the market. When it comes to corrosion resistance, strength, and fabricability, nickel alloy 625 strip is one of the best options for your application.

Inconel alloy 625 strips also referred to as the UNS N06625, W.Nr. 2.4856 refers to strong solution that has been strengthen by the presence on nickel making it have a high resistance to corrosion, great tensile strength, high oxidation and excellent fatigue properties.

Properties of this Inconel alloy 625 strips make it an excellent product for use in the manufacture of chemical equipment’s, aerospace structural parts, and aero-engine parts.

Inconel alloy 625 strips has a density of 8.44 g/cm³.

Difference Between Inconel 600 Strip and Inconel 625 Strip

As you can see from their introduction and products types, Inconel alloy Inconel 600 strip and Inconel 625 strip are very different. Depending on what you are looking for in your project, they each have benefits and drawbacks. For a side by side comparison, you breakdown the differences even further.

Chemical Composition

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Chemical Composition

Inconel 600 Alloy Strip Chemical Composition

The chemical components of grade Inconel 600 strip is summarized in the following table:

| Grade | Standard | C | Si | Mn | P | S | Cr | Ni | Cu |

| Inconel 600 | ASTM B 168/ASME SB 168 | ≤0.15 | ≤0.50 | ≤1.00 | ≤0.015 | ≤0.015 | 14.00-17.00 | ≥72 | ≤0.5 |

Inconel 625 Alloy Strip Chemical Composition(%) | ||

| Element | Min | Max |

| C | – | 0.1 |

| Si | – | 0.5 |

| Mn | – | 0.5 |

| P | – | 0.015 |

| S | – | 0.015 |

| Al | – | 0.4 |

| Cr | 20 | 23 |

| Cu | 1 | 1.4 |

| Fe | – | 5 |

| Mo | 8 | 10 |

| Nb | 3.15 | 4.15 |

| Ni | Balance | |

| Ti | – | 0.4 |

Corrosion Resistance

In nickel alloy strips, the inherent nickel element significantly contributes to effective corrosion resistance. This makes both Inconel 600 strip and Inconel 625 strip highly commendable for their corrosion-resistant properties.

Alloy 625 boasts a greater chromium content when compared to Alloy 600. This heightened chromium content serves as the primary contributor to the alloy’s remarkable oxidation resistance. Consequently, Inconel 625 strip outperforms Inconel 600 strip in terms of antioxidation capability.

Alloy 600 lacks molybdenum, whereas alloy 625 incorporates over 8% molybdenum, attributing to its added resistance against reduction. This advantageous feature is absent in Alloy 600.

Hence, when juxtaposed, it’s evident that Inconel 625 strip exhibits notably superior comprehensive corrosion resistance.

Mechanical Properties

Inconel Alloy 600 Strip Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| Inconel 600 | 500 | 180 | 30 | – | – |

Inconel 625 Strip Mechanical Properties

| Temper | Annealed (Grade1) | Solution-treated (Grade 2) | ||

| Tensile Rm | 120 | ksi (min) | 100 | ksi (min) |

| Tensile Rm | 827 | MPa (min) | 690 | MPa (min) |

| R.p. 0.2% Yield | 60 | ksi (min) | 40 | ksi (min) |

| R.p. 0.2% Yield | 414 | MPa (min) | 276 | MPa (min) |

| Elongation | 30 | % (min) | 30 | % (min) |

Applications

Inconel Alloy 600 Strip Applications

- Retorts

- Muffles

- Roller hearths

- Furnace components

- Heat-treating applications

Inconel Alloy 625 Strip Applications

Inconel 625 alloy has a high level resistance against corrosion which makes it very common in the gas and oil industry. 625 alloys are also very popular in the aerospace industry.

- Aerospace

- Chemical Processing

- Heat Exchangers

- Construction

- Bridges

- Petrochemical Industry

- Ship Building

- Engineering

- General Structural Purposes

Standards

Inconel Alloy 600 Strips Standards

Strip&Foil: ASTM B168, ASTM B906

Inconel Alloy 625 Strips Standards

Strip&Foil: ASTM B 443/ASTM SB 443, SAE/AMS 5599 & 5869

Conclusion

Because of its heightened chromium and molybdenum content, Inconel 625 alloy strip showcases enhanced overall corrosion resistance compared to Inconel 600 strip.

Owing to the synergistic impact of diverse strengthening components, alloy 625 strip demonstrates superior mechanical characteristics in comparison to alloy 600 strip.

The outcome of this heightened performance and intricate composition is reflected in a higher cost, making the more economical alloy 600 strip a preferred choice whenever feasible.

Here at HZW, we specialize in crafting cost-effective Inconel 600 strip and Inconel 625 strip products. If your requirements align with these offerings, please don’t hesitate to get in touch with us.