Inconel 600

Introduction

Overview of Inconel 600 Alloy

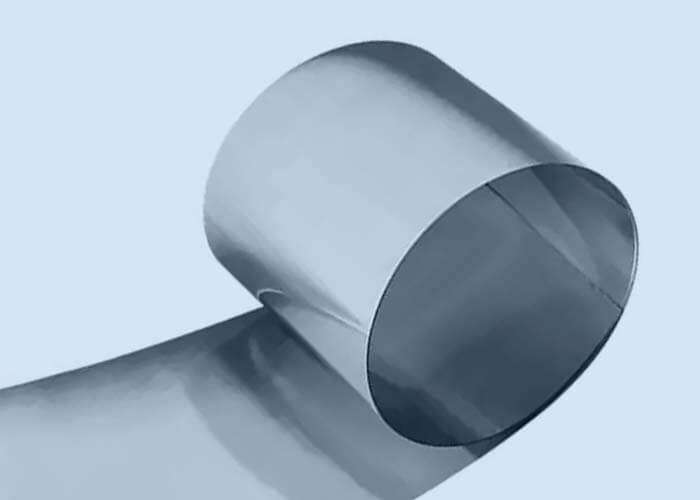

Inconel 600 (UNS N06600 / W.Nr. 2.4816) is a standard engineering material for applications which require resistance to corrosion and heat.

The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability.

The high nickel content gives the alloy resistance to corrosion by many organic and inorganic compounds and also makes it virtually immune to chloride-ion stress-corrosion cracking. Chromium confers resistance to sulfur compounds and also provides resistance to oxidizing conditions at high temperatures or in corrosive solutions. The alloy is not precipitation hardenable; it is hardened and strengthened only by cold work.

The versatility of Inconel alloy 600 has led to its use in a variety of applications involving temperatures from cryogenic to above 2000°F (1095°C).

The alloy is used extensively in the chemical industry for its strength and corrosion resistance. Applications include heaters, stills, bubble towers and condensers for processing of fatty acids; evaporator tubes, tube sheets and flaking trays for the manufacture of sodium sulfide; and equipment for handling abietic acid in the manufacture of paper pulp.

The alloy’s strength and oxidation resistance at high temperatures make it useful for many applications in the heat-treating industry. It is used for retorts, muffles, roller hearths and other furnace components and for heat-treating baskets and trays.

In the aeronautical field, Inconel alloy 600 is used for a variety of engine and airframe components which must withstand high temperatures. Examples are lockwire, exhaust liners and turbine seals. INCONEL alloy 600 is used in the electronic field for such parts as cathode-ray tube spiders, thyratron grids, tube support members and springs.

The alloy is a standard material of construction for nuclear reactors. It has excellent resistance to corrosion by high-purity water, and no indication of chloride-ion stress-corrosion cracking in reactor water systems has been detected. For nuclear applications, the alloy is produced to exacting specifications and is designated INCONEL alloy 600T.

Corrosion Resistance of Inconel 600

The composition of Inconel alloy 600 enables it to resist a variety of corrosives.

The chromium content of the alloy makes it superior to commercially pure nickel under oxidizing conditions, and its high nickel content enables it to retain considerable resistance under reducing conditions. The nickel content also provides excellent resistance to alkaline solutions.

The alloy has fair resistance to strongly oxidizing acid solutions.

However, the oxidizing effect of dissolved air alone is not sufficient to insure complete passivity and freedom from attack by air-saturated mineral acids and certain concentrated organic acids.

Inconel 600 Alloy Applications

Inconel Alloy 600 can be used in a variety of applications including:

- Heat treating muffles and retorts

- Vacuum furnace fixtures

- Nitriding furnaces and baskets

- Chlorination equipment to 538°C

- Titanium dioxide plants

Inconel 600 Tags

- UNS Number: N06600

- Werkstoff Number: 2.4816

- Standards: ASTM B163, B166, B167, B168, B516, B517, B564, B366, AMS 5540, 5665, B751, B775, B829

Inconel 600 Quality Products

Technical Data

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Alloy 600 | 2.4816 | N06600 | – | – | – | – | – | – |

| Grade | Standard | C | Si | Mn | P | S | Cr | Ni | Cu |

| Inconel 600 | ASTM B 168/ASME SB 168 | ≤0.15 | ≤0.50 | ≤1.00 | ≤0.015 | ≤0.015 | 14.00-17.00 | ≥72 | ≤0.5 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.47 g/cm3 | 1413 °C (2575 °F) | 550-1170Mpa | 170-1100Mpa | 55% – 2% |

Related Resources

Inconel Alloy: A Comprehensive Guide

What Is Inconel Alloy? Inconel alloys stand as advanced nickel-chromium superalloys designed to excel in high-temperature, corrosive, and oxidizing conditions. Their applications span the most challenging environments, including chemical processing reaction chambers, valves, polymer granule manufacturing, military uses, gas turbine components, oil fields, and high-end marine applications. Typically composed of nickel, chromium, iron/steel, and additional

Difference Between Inconel 600 Strip and Inconel 625 Strip

Both Inconel 600 strip and Inconel 625 strip are solid solution strengthened Inconel alloys strips. Due to some chemical composition differences, these two alloys strips have different corrosion resistance and strength. Determining the suitable choice for your alloy strip project can be perplexing. This article aims to delineate the disparities between these two nickel-based alloys

Difference Between Inconel 600 Strip and Inconel 601 Strip

Inconel 600 strip and Inconel 601 strip are two frequently used nickel alloys strips. Both alloys have good high temperature properties. Among them, Inconel 601 added more chromium on the basis of Inconel 600. So their main difference is the difference in antioxidant properties. Determining the suitable choice for your alloy strip project can be

Difference Between Inconel 600 Strip and Incoloy 800 Strip

Inconel 600 strip and Incoloy 800 strip are two frequently utilized nickel alloys strips. Their functionalities exhibit resemblances, with both alloys catering to diverse industrial applications. However, across all aspects, Inconel 600 alloy strip showcases superior performance when compared to Incoloy 800 alloy strip. Conversely, Incoloy 800 boasts a more economical cost and can serve

What Is Inconel 600 Strip?

What Is Inconel 600 Strip? Inconel 600 strip is a nickel-chromium alloy strip designed for use from cryogenic to elevated temperatures in the range of 2000 deg F(1093 deg C). It is non magnetic, has excellent mechanical properties, and presents the desirable combination of high strength and good weldability under a wide range of temperatures.

More Grades