Stainless steel strips are the extension products of ultra-thin stainless steel plates, usually long and narrow stainless steel strips are manufactured to meet the demands of various industrial and mechanical areas.

Stainless steel strip is also called stainless steel strip coil. The maximum width of its size shall not exceed 1220mm, but the length of coil is not limited.

According to the processing method, the stainless steel strips can be divided into cold-rolled stainless steel strips and hot-rolled stainless steel strips.

Stainless steel strips have excellent strength, precision surface finish, and are widely used in many industries such as aerospace, petrochemicals, automobiles, textiles, electronics, home appliances, computers, and precision parts processing.

What Is Cold-Rolled Stainless Steel Strip?

Cold-rolled stainless steel strip refers to a product that is manufactured through a cold rolling process applied to stainless steel coils.

Stainless steel strip coil is rolled by cold rolling mill at room temperature.

The conventional thickness is between 0.1mm and 3mm, and the width is between 100mm and 2000mm.

Cold rolled stainless steel strip has many advantages such as smooth and flat surface, high accuracy, good mechanical properties, and can be rolled or processed into coated steel plates.

The sequence of the production process is pickling, normal temperature rolling, process lubrication, annealing, leveling, precision cutting, and packaging.

Cold-rolled stainless steel strip is widely used in industries such as automotive, aerospace, construction, electronics, and manufacturing.

The precise dimensions, consistent thickness, and high-quality surface finish of cold-rolled stainless steel strip make it desirable for applications where tight tolerances and aesthetic appearance are crucial.

Compared to hot-rolled stainless steel strips, cold-rolled strips generally exhibits better dimensional control, improved surface quality, and higher strength.

However, it is important to note that cold-rolled stainless steel strip typically has a narrower range of available sizes and may be more expensive due to the additional processing steps involved.

Overall, cold-rolled stainless steel strip offers excellent properties and versatility, making it a preferred choice in various industries where high-quality, precision-engineered components are required.

What Is Hot-Rolled Stainless Steel Strip?

Hot rolled stainless steel strip is a strip with a thickness of 1.80mm to 6.00mm and a width of 50mm to 1200mm, which is produced by the hot rolling mill.

Hot-rolled stainless steel strip refers to a product that is produced through a hot rolling process applied to stainless steel coils.

Hot rolled stainless steel strip has many advantages such as low hardness, easy processing and good extensibility.

Its production process is pickling, high temperature rolling, process lubrication, annealing, smoothing, fine cutting, and packaging.

Hot-rolled stainless steel strip has some distinctive characteristics. It typically has a darker, rougher surface compared to cold-rolled stainless steel strip due to the scale formed during the heating process.

The mechanical properties of hot-rolled strip include lower hardness and higher ductility compared to its cold-rolled counterpart. Hot-rolled strip also tends to have a wider dimensional tolerance range.

Hot-rolled stainless steel strip finds applications in various industries. It is commonly used in structural components, construction materials, automotive parts, pipe and tube manufacturing, and general fabrication. The material’s lower cost and faster production process make it suitable for applications where tight dimensional tolerances and a smooth surface finish are not critical.

Differences Between Cold-Rolled Stainless Steel Strip And Hot-Rolled Stainless Steel Strip

First, the yield strength of cold-rolled stainless steel strips are better than hot ones, but and the malleability and toughness of hot-rolled stainless steel strips are better.

Secondly, the thickness of cold-rolled stainless steel strip is ultra-thin, while the thickness of hot-rolled stainless steel strip is a bit thick.

Thirdly, for the surface finish quality, appearance and dimensional accuracy of cold-rolled stainless steel strips are better than those of hot-rolled stainless steel strips.

What Are Stainless Steel Strips Grades?

Common use stainless steel strips grades are often represented by digital symbols.

There are 200 series, 300 series, and 400 series.

They are expressed in the United States, such as 201, 202, 304, 316, 410, 420, 430, etc.

Chinese stainless steel grades are It is indicated by element symbols plus numbers, such as 1Cr18Ni9Ti, 0Cr18Ni9, 00Cr19Ni10, 1Cr17, 3Cr13, 1Cr17Ni7, etc.

The numbers indicate the corresponding element content.

The stainless steel strips can be divided into normal austenitic grade, ferritic grade, martensitic grade, duplex grade, precipitation hardening grade and super austenitic grade.

200 Series Stainless Steel Strips

Chromium-nickel-manganese austenitic stainless steel

300 Series Stainless Steel Strips

Chromium-nickel austenitic stainless steel

201 Stainless Steel Strip

Grade 201 stainless steel strip is a lower-cost alternative to the conventional Cr-Ni austenitic stainless steels, such as 304 strips.

202 Stainless Steel Strip

202 stainless steel strip is one of the 200 series stainless steel strips, and China standard grade is 1Cr18Mn8Ni5N.

301 Stainless Steel Strip

Good extension ability, used for mould products. It can also be hardened at machine speed. Good weldability. Abrasion resistance and fatigue strength are better than 304 stainless steel strip.

301 stainless steel strip is a type of austenitic stainless steel strip that contains chromium and nickel.

It is commonly used in a variety of applications, including automotive and aerospace components, springs, washers, and more.

This type of stainless steel strip is known for its excellent corrosion resistance, high strength, and good ductility.

The “301” in 301 stainless steel strip refers to the ASTM designation for this particular alloy. The “301” designation indicates that this stainless steel strip meets certain standards for chemical composition, mechanical properties, and other factors.

In general, 301 stainless steel strip is made up of 16% to 18% chromium and 6% to 8% nickel, with small amounts of other elements such as carbon, manganese, and silicon.

One of the key characteristics of 301 stainless steel strip is its high tensile strength. Tensile strength refers to the amount of force that a material can withstand before it begins to deform or break. 301 stainless steel strip has a tensile strength of up to 180,000 psi, which makes it ideal for applications where high strength is required.

In addition to its high strength, 301 stainless steel strip is also known for its good ductility. Ductility refers to the ability of a material to be stretched or deformed without breaking. This property makes 301 stainless steel strip well-suited for applications that require forming or bending, such as springs, clips, and washers.

Another important characteristic of 301 stainless steel strip is its corrosion resistance. The chromium in the alloy forms a passive layer on the surface of the steel, which protects it from corrosion. This makes 301 stainless steel strip an excellent choice for applications that will be exposed to corrosive environments, such as marine or chemical processing applications.

There are several different finishes that can be applied to 301 stainless steel strip, depending on the application. These include a bright annealed finish, a temper rolled finish, and a skin-passed finish. Each of these finishes has its own unique properties, such as increased surface hardness or improved flatness.

One of the most common applications for 301 stainless steel strip is in the production of springs. Springs made from this material are known for their high strength, good fatigue resistance, and excellent corrosion resistance. 301 stainless steel strip is also used in a variety of other applications, such as in the production of aircraft components, automotive parts, and electronic components.

In conclusion, 301 stainless steel strip is a popular choice for a wide range of applications thanks to its excellent combination of high strength, good ductility, and corrosion resistance. It is a versatile material that can be used in a variety of industries, from automotive and aerospace to electronics and chemical processing. With its unique properties and ability to withstand harsh environments, 301 stainless steel strip is an ideal material for a wide range of applications.

304 Stainless Steel Strip

304 grade is a common material in stainless steel area, with a density of 7.93 g/cm³, which is also called 18/8 stainless steel in the industry. GB standard is 0Cr18Ni9.

304 stainless steel strip has good weldability. These strips products can be used for vessel parts, stainless steel welding pipes, stainless steel flexible hose and corrugated pipe, etc.

304L Stainless Steel Strip

It is a variant of 304 stainless steel with lower carbon content, used in occasions where welding is required. The lower carbon content minimizes the precipitation of carbides in the heat-affected zone near the weld, and the precipitation of carbides may cause stainless steel to produce intergranular corrosion (welding erosion) in certain environments.

309S And 310S Stainless Steel Strips

Nickel and chromium content are relatively high, in order to improve the oxidation resistance and creep strength of steel at high temperatures.

309S stainless steel strip has high chromium and low nickel content, It can be utilized in sulfur containing atmospheres up to 1000 degree.

310S stainless steel strip is austenitic chromium-nickel stainless steel with good oxidation resistance and resistance, corrosion and high temperature resistance.

310S stainless steel strips are specially used to manufacture electric furnace tubes. The austenitic stainless steel adds carbon content, the strength is improved due to its solid solution strengthening effect.

Therefore, it has high strength at high temperature. The melting point is 1470℃, and it starts to soften at 800℃, and the allowable stress continues to decrease.

316Ti Stainless Steel Strip

Grade 316Ti stainless steel strip contains a small amount of titanium content. Titanium content is typically only around 0.2% to 0.7%.

The titanium atoms stabilise the structure of the grade 316 material at temperatures over 800 degree.

This prevents carbide precipitation at the grain boundaries and protects the metal strips from corrosion.

The main advantage of 316Ti stainless steel strip is that it can be held at higher temperatures for a longer period without sensitisation (precipitation) occurring.

And 316Ti strip retains physical and mechanical properties similar to standard grade of 316 strip.

316L And 317L Stainless Steel Strips

Contains aluminum, so the resistance to pitting corrosion in marine and chemical industrial environments is much better than 304 stainless steel.

316L stainless steel strip is almost identical to 316 grade strip.

316L stainless steel strip has lower carbon content imparts even better corrosion resistance than 316.

In addition, compared with conventional stainless steel strip, 317L stainless steel strip has higher ductility, stress corrosion resistance, compressive strength and high temperature resistance.

321 And 347 Stainless Steel Strips

These grades stainless steel stabilized with titanium, niobium plus tantalum, and niobium respectively. They are suitable for welding components used at high temperatures.

321 austenitic stainless steel strip has good corrosion resistance in the atmosphere and is widely used in petrochemical, electric power, bridge and automobile industries.

However, the “stainlessness” of 321 stainless steel is not absolute. Due to the special service environment, 321 stainless steel will also corrode.

Factors such as medium concentration, PH value, and temperature will have a greater impact on the corrosion resistance of 321 stainless steel.

347 stainless steel strip is one of stabilized stainless steel strips which offers as its main feature an excellent resistance to intergranular corrosion following exposure to temperatures in the chromium carbide precipitation up to 800 degree.

400 Series Stainless Steel Strips

Ferritic and martensitic stainless steel

409 Stainless Steel Strip

The cheapest model (British and American), usually used as car exhaust pipe, is a ferritic stainless steel (chrome steel).

410 Stainless Steel Strip

Martensite (high-strength chromium steel), good wear resistance, poor corrosion resistance.

420J2 Stainless Steel Strip

420J2 stainless steel strip has a certain degree of wear resistance and corrosion resistance, high hardness.

420J2, is is also called 3Cr13 steel, one kind of martensitic stainless steel, used after quenching and tempering.

Compared with 1Cr13 and 2Cr13 steel, it has higher strength, hardness and hardenability, but its corrosion resistance and thermal stability below 700℃ are lower than that of 1Cr13 and 2Cr13 steel.

Cold workability and welding performance are not good, heat treatment should be done immediately after welding to prevent cracking.

It has better cutting performance in the annealed state.

430 Stainless Steel Strip

430 stainless steel strip is a general purpose stainless steel with good corrosion resistance.

It has better thermal conductivity than austenite grade stainless steel strip, a smaller thermal expansion coefficient than austenite strip, heat fatigue resistance.

Due to addition of stabilizing element titanium, it has good mechanical properties of welding.

Because of its chromium content, it is also called 18/0 or 18-0. Compared with 18/8 and 18/10, it contains slightly less chromium, and the hardness is correspondingly lower.

Ferritic stainless steel, for decoration, such as car accessories.

Good formability, but poor temperature resistance and corrosion resistance.

440 Stainless Steel Strip

High-strength cutting tool steel with slightly higher carbon content.

After proper heat treatment, higher yield strength can be obtained.

The hardness can reach to 58HRC, which is one of the most hardest stainless steel. The most common application example is “razor blades”.

There are three commonly used models: 440A, 440B, 440C, and 440F (easy processing type).

Duplex 2205 Stainless Steel Strip

2205 stainless steel strip is a duplex stainless steel strip composed of 22% chromium, 2.5% molybdenum and 4.5% nickel-nitrogen alloy.

It has high strength, good impact toughness and good overall and local stress corrosion resistance.

The yield strength of duplex 2205 stainless steel strip is more than twice that of normal austenitic stainless steel strip.

This feature enables engineers and designers to reduce weight when designing related products, making this strip more cost-effective than 316L stainless steel strip and 317L stainless steel strip.

This strip is especially suitable for the temperature range of from -50°F to +600°F.

Super Duplex 2507 Stainless Steel Strip

2507 stainless steel strip is a super duplex stainless steel strip composed of 25% chromium, 4% molybdenum and 7% nickel alloy.

Super duplex 2507 stainless steel strip is a ferritic-austenitic stainless steel strip, which combines the most beneficial properties of many ferritic stainless steel strip(430 stainless steel strip) and austenitic stainless steel strip(such as 304L stainless steel strip, 310S stainless steel strip, 321 stainless steel strip, 347 stainless steel strip).

Because the 2507 stainless steel strip contains high contents of chromium and molybdenum, so it has extremely good resistance to pitting, crevice corrosion and uniform corrosion.

The dual-phase microstructure ensures that the 2507 stainless steel strip has a high resistance to stress corrosion cracking, and the mechanical strength of it is also high.

904L Stainless Steel Strip

904L stainless steel strip is a low-carbon, high-nickel, molybdenum super austenitic stainless steel.

It has good activation-passivation transformation ability and excellent corrosion resistance.

It has good corrosion resistance in non-oxidizing acids, good pitting corrosion resistance in neutral chloride-containing application.

17-4PH Stainless Steel Strip | 630 Precipitation Hardening Strip

17-4 PH stainless steel strip, also called 630 precipitation hardening stainless steel strip.

17-4PH alloy is a precipitation, hardening, martensitic stainless steel composed of copper, niobium/columb.

After heat treatment, the mechanical properties of the strip product are more perfect, and can reach a compressive strength of up to 1100-1300 Mpa (160-190 ksi).

Grade 17-4 PH stainless steel strip cannot be used at temperatures higher than 300°C (572°F) or very low temperatures.

It has good corrosion resistance to the atmosphere and diluted acids or salts.

Its corrosion resistance is the same as 304 stainless steel strip and 430 stainless steel strip.

17-7PH Stainless Steel Strip | 631 Precipitation Hardening Strip

17-7 PH stainless steel strip, also called 631 precipitation hardening stainless steel strip.

It is a precipitation hardening stainless steel strip that provides high strength and hardness, excellent fatigue properties, good corrosion resistance, good formability, and minimum distortion upon heat treatment.

The alloy strip provides valuable property combinations particularly well suited for aerospace applications.

This special alloy strip also provides benefits for other applications requiring high strength and good corrosion resistance, as well as excellent properties for flat springs at temperatures up to 600°F (316°C).

According to the processing method, the edge of 17-7 PH stainless steel strip can be produced as slit and round types.

The conventional thickness is between 0.1mm and 3.0mm, and the width is less than 600mm.

Different length can be produced according to your detailed request.

UNS N08926 Stainless Steel Strip

UNS N08926 stainless steel strip is a super austenitic stainless steel strip.

N08926 is the UNS standard grade for this metal strip.

Alloy 926 stainless steel strip is the common industry name, it is the AISI standard grade.

UNS N08926 stainless steel strip has very high resistance to pitting and crevice corrosion in media and acidic environments containing sulfur and hydrogen, can effectively resist chloride ion stress corrosion, and also has good corrosion resistance in oxidizing and reducing media, good stability, mechanical properties slightly better than 904L stainless steel strip.

It can be used in such temperature from -196 degree to 400 degree.

The chromium content in Alloy 926 (1.4529, N08926) super austenitic stainless steel strip is usually from 19.0 to 21.0%, and the nickel content is from 24.0 to 26.0%.

This feature can be protected under high temperature conditions and is more resistant to high temperature than traditional chromium nickel stainless steel such as 304 stainless steel strip.

840 Stainless Steel Strip

Grade 840 stainless steel strip is a titanium and aluminum bearing austenitic stainless steel offering elevated-temperature scaling resistance superior to conventional chromium-nickel stainless steel strips, such as grade 304 strip.

The oxidation resistance of 840 alloy strip compares favorably with higher alloyed grades up to 1900ºF (1038ºC), making it a good candidate alloy for use in sheathing for electric heating elements, automotive emission control systems, and other applications where resistance to elevated temperature degradation is important.

840 alloy strips are slitted from mother coils.

Polished Stainless Steel Strips

Polished stainless steel strips are the strips with polishing bright surface finish produced by different polishing equipment and method.

As we know, stainless steel strips will form a black or gray oxide scale on its surface finishes after thermal processing, mechanical processing or placing it for a certain period of time.

Its main components are Cr2O3, NiO and very insoluble FeO and Cr2O3,

These components affects the appearance quality. What’s more, they also affect the performance of the steel strip product.

As a mature surface treatment method, stainless steel polishing has been widely used.

Polishing can further improve the corrosion resistance and bright effect of stainless steel strips.

Polished stainless steel strips are divided into main five types according to their organizational characteristics: austenite, austenite-ferrite, ferrite, martensite and precipitation hardening, which can be selected in real application.

Thin Stainless Steel Strips

Ultra-thin stainless steel strips are the high-end products in the field of stainless steel strips.

At present market, there are many 0.05mm thickness soft temper thin stainless steel strips.

Different from conventional stainless steel strips, super precision thin stainless steel strips refer to a special ultra-thin cold-rolled stainless steel strips whose thickness is generally between 0.05 mm and 0.5 mm, and it is called stainless steel foil below 0.05 mm.

Hand-tear strip is also called precision stainless steel foils, which represents the advanced technology of TISCO.

TISCO capability of stainless steel strip foil thickness is 0.02mm.

Precision Stainless Steel Strip

Precision stainless steel strip is a cold rolled strip made from high quality stainless steel coil.

The most common grades are 201, 301, 304 and 316L. The strip may be uncoated or coated with a surface finish that enhances its corrosion resistance properties. It is available in thicknesses from 0.02mm to 3.0mm.

Precision stainless steel strip has excellent mechanical properties at room temperature and can be readily fabricated into parts by machining processes such as turning and drilling. It is also weldable by conventional methods, although welding must be done carefully because of the low melting point of the material.

Precision stainless steel strip is used by manufacturers in industries such as aerospace, automotive, marine, oil and gas, petrochemical, food processing and medical equipment.

Precision stainless steel strip can be manufactured in different grades depending on the desired characteristics of the final product. For example, grade 304 precision stainless steel strip is more resistant to corrosion than grade 321 precision stainless steel strip but both types are still suitable for use in marine environments since they will not rust or corrode over time.

Of course, there are many other grades stainless steel. More information, you can click stainless steel strips link for checking.

Stainless Steel Strips Thickness Range

Stainless Steel Strip 1mm Thickness

Stainless steel strip 1mm thickness strip is a kind of stainless steel narrow plate which is produced in the cold-rolled and annealed process.

1mm thickness stainless steel strip has high strength, good quality of surface, beautiful appearance, light weight, easy processing and other characteristics.

Stainless Steel Strip 2mm Thickness

Stainless steel strip 2mm thickness is a very common industrial material.

Stainless steel strip 2mm thickness has excellent mechanical properties, good corrosion resistance and better toughness than stainless steel plates with the same hardness.

The stainless steel strip 2mm thickness is polished, the surface is smooth and beautiful, the wear resistance is high, the plasticity is good, it can be made of various shapes, the installation is convenient, and it saves time and effort.

Stainless Steel Strip 3mm Thickness

Stainless steel strip 3mm thickness is annealed and pickled by cold rolling production line. The 3mm thickness stainless steel strip is controlled by the rolling pressure.

Stainless steel strip 3mm thickness can be divided into ordinary stainless steel strip, special stainless steel strip, spring stainless steel strip, semi-hard stainless steel strip, fully hard stainless steel strip, etc. according to different treatment methods.

3mm thickness stainless steel strips can also be divided into 2B, BA, 8K and other surface treatment methods according to different surface requirements.

Stainless Steel Strip 5mm Thickness

Stainless Steel Strips Chemical Compositions

| Stainless Steel Chemical Composition(%) | ||||||||||

| Grade | C, ≤ | Mn, ≤ | P, ≤ | S, ≤ | Si, ≤ | Cr | Ni | Mo | N, ≤ | Other Elements, ≤ |

| 304 | 0.08 | 2.00 | 0.05 | 0.03 | 1.00 | 18.0-20.0 | 8.0-11.0 | – | – | – |

| 304L | 0.03 | 2.00 | 0.05 | 0.03 | 1.00 | 18.0-20.0 | 8.0-12.0 | – | – | – |

| 316L | 0.03 | 2.00 | 0.05 | 0.03 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | – | – |

| 321 | 0.08 | 2.00 | 0.05 | 0.03 | 1.00 | 17.0-19.0 | 9.0-12.0 | – | 0.10 | ≥ Ti 5×(C+N), ≤ 0.70 |

| 201 | 0.15 | 5.50-7.50 | 0.06 | 0.03 | 1.00 | 16.0-18.0 | 3.5-5.5 | – | 0.25 | – |

| 202 | 0.15 | 7.50-10.00 | 0.06 | 0.03 | 1.00 | 17.0-19.0 | 4.0-6.0 | – | 0.25 | – |

| 301 | 0.15 | 2.00 | 0.05 | 0.03 | 1.00 | 16.0-18.0 | 6.0-8.0 | – | 0.10 | – |

| 309S | 0.08 | 2.00 | 0.05 | 0.03 | 1.00 | 22.0-24.0 | 12.0-15.0 | – | – | – |

| 310S | 0.08 | 2.00 | 0.05 | 0.03 | 1.50 | 24.0-26.0 | 19.0-22.0 | – | – | – |

| 316Ti | 0.08 | 2.00 | 0.05 | 0.03 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.10 | ≥ Ti 5 × (C + N), ≤0.70 |

| 317L | 0.03 | 2.00 | 0.05 | 0.03 | 0.75 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | 0.10 | – |

| 321 | 0.08 | 2.00 | 0.05 | 0.03 | 1.00 | 17.0-19.0 | 9.0-12.0 | – | 0.10 | ≥ Ti 5 × (C + N), ≤ 0.70 |

| 347 | 0.08 | 2.00 | 0.05 | 0.03 | 1.00 | 17.0-19.0 | 9.0-12.0 | – | – | ≥ Cb 10 × C, ≤ 1.00 |

| 2205 | 0.03 | 2.00 | 0.03 | 0.02 | 1.00 | 22.0-23.0 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | – |

| 2304 | 0.03 | 2.50 | 0.04 | 0.03 | 1.00 | 21.5-24.5 | 3.0-5.5 | 0.05-0.60 | 0.05-0.60 | – |

| 2507 | 0.03 | 1.20 | 0.04 | 0.02 | 0.80 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 | Cu ≤0.50 |

| 410S | 0.08 | 1.00 | 0.04 | 0.03 | 1.00 | 11.5-13.5 | 0.60 | – | – | – |

| 430 | 0.12 | 1.00 | 0.04 | 0.03 | 1.00 | 16.0-18.0 | – | – | – | – |

| 434 | 0.12 | 1.00 | 0.04 | 0.03 | 1.00 | 16.0-18.0 | – | 0.75-1.25 | – | |

| 440A | 0.60-0.75 | 1.00 | 0.04 | 0.03 | 1.00 | 16.0-18.0 | – | ≤0.75 | – | – |

| 440B | 0.75-0.95 | 1.00 | 0.04 | 0.03 | 1.00 | 16.0-18.0 | – | ≤0.75 | – | – |

| 440C | 0.95-1.20 | 1.00 | 0.04 | 0.03 | 1.00 | 16.0-18.0 | – | ≤0.75 | – | – |

| 444 | 0.03 | 1.00 | 0.04 | 0.03 | 1.00 | 17.5-19.5 | 1.00 | 1.75-2.50 | 0.04 | Ti+Cb 0.20+4 × (C+N)-0.80 |

| 904L | 0.02 | 2.00 | 0.05 | 0.04 | 1.00 | 19.0-23.0 | 23.0-28.0 | 4.00-5.00 | 0.10 | Cu 1.00-2.00 |

| PH 13-8Mo | 0.05 | 0.20 | 0.01 | 0.01 | 0.10 | 12.25-13.25 | 7.5-8.5 | – | – | – |

| 15-5 PH | 0.07 | 1.00 | 0.04 | 0.03 | 1.00 | 14.0-15.5 | 3.5-5.5 | – | – | 2.5-4.5 Cu; 0.15-0.45 Nb |

| 17-4 PH | 0.07 | 1.00 | 0.04 | 0.03 | 1.00 | 15.5-17.5 | 3.0-5.0 | – | – | 3.0-5.0 Cu; 0.15-0.45 Nb |

| 17-7 PH | 0.09 | 1.00 | 0.04 | 0.04 | 1.00 | 16.0-18.0 | 6.5-7.75 | – | – | 0.75-1.5 Al |

From this file, you can learn more about all grades stainless steel strips chemical compositions.

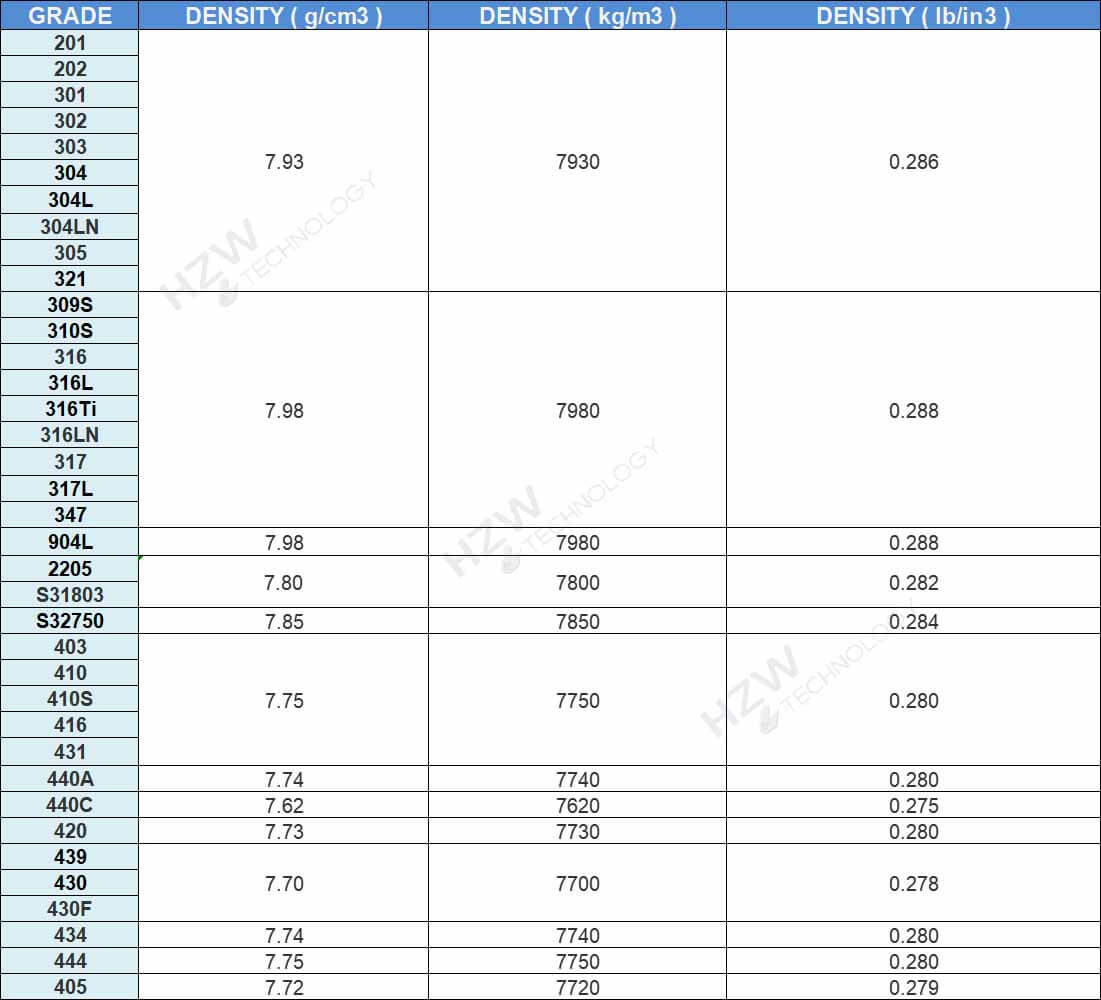

Stainless Steel Strips Density

Stainless steel strip density signifies the mass of the substance within a given unit of volume.

This property is a characteristic feature of stainless steel, with its density typically falling between 7.6 g/cm³ and 8.0 g/cm³.

Stainless steel is a widely utilized material composed of a minimum of 10.5% Chromium, along with other elements that combine to create its distinct structure.

These components includes Carbon, Silicon, Manganese, Phosphorus, Sulfur, Nickel, Molybdenum, Titanium and Copper. This steel is recognized for its exceptional strength and remarkable resistance to corrosion.

What Is Stainless Steel Strips Application?

Precision stainless steel strips are widely used in various sectors of the national economy such as industry and civil due to its high strength, corrosion resistance, oxidation resistance, processability and service performance, wear resistance and good appearance.

With the advancement of science and technology, stainless steel strips application fields are still expanding and extending, and it has spread all over major industries such as aerospace, petrochemicals, automobiles, textiles, electronics, home appliances, computers, and precision machining, etc. The demand for products also grow rapidly.

Generally speaking, the application industry can be divided into the following two categories:

- Precision stainless steel strips products for high-end industries: aerospace industry; petrochemical industry; precision electronics industry; medical equipment; precision instrument.

- Precision stainless steel strips products for mid-range industries: electronic information industry; household appliances industry; kitchen and tableware; building decoration industry; hardware industry.

How To Manufacture Stainless Steel Strips?

Our high quality stainless steel strip is available in total annealed condition as well as a variety of hardness choice.

We welcome every order of yours that you need in small and large quantities.

Our factory is well-equipped with precision slitting machines and advanced 20-High SendZimir Mill that are able to mass produce your strips.

Our staff and precision machines are well-equipped with all the latest technology to give you the finest work and make sure you get the good-quality stainless steel strips within the planned deadlines.

Want to know how to produce 1 roll stainless steel strip in our factory?

What Are Stainless Steel Strips Flatness And Straightness?

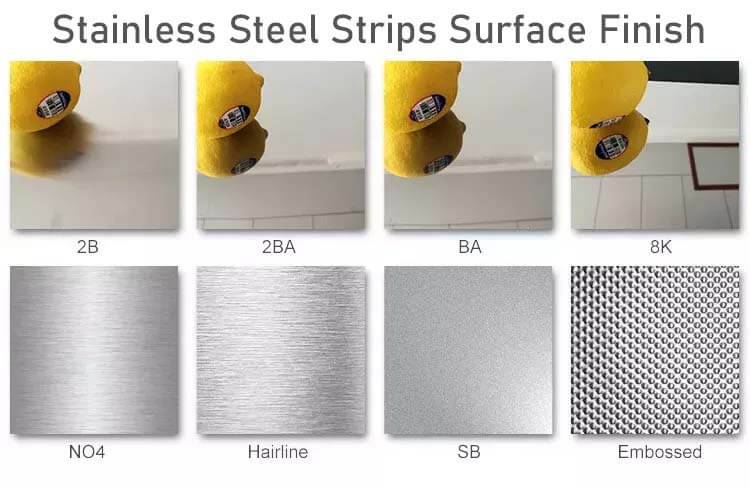

What Is Stainless Steel Strips Surface Finish?

Stainless steel has become a widely used metal material for its excellent corrosion resistance, good mechanical properties and processing properties.

Through different processing methods of cold rolling and surface reprocessing after cold rolling, the surface finish of stainless steel can have different types.

The surface processing of stainless steel strips have NO.1, 2B, No. 4, HL, No. 6, No. 8, BA, TR hard, Rerolled bright 2H, polishing bright and other surface finishes, etc.

- NO.1: No. 1 surface refers to the surface obtained by heat treatment and pickling after hot rolling of the stainless steel strip. It is to remove the black oxide scale produced during hot rolling and heat treatment by pickling or similar treatment methods. This is No. 1 surface processing. The No.1 surface is silvery white and matt. Mainly used in heat-resistant and corrosion-resistant industries that do not require surface gloss, such as alcohol industry, chemical industry and large containers.

- 2B: The surface of 2B is different from the 2D surface in that it is smoothed with a smooth roller, so it is brighter than the 2D surface. The surface roughness Ra value measured by the instrument is 0.1~0.5μm, which is the most common processing type. This kind of stainless steel strip surface is the most versatile, suitable for general purposes, which is widely used in the chemical, paper, petroleum, medical and other industries, and can also be used as a building curtain wall.

- TR Hard Finish: TR stainless steel is also called hard steel. Its representative steel grades are 304 and 301, they are used for products that require high strength and hardness, such as railway vehicles, conveyor belts, springs and gaskets. The principle is to use the work hardening characteristics of austenitic stainless steel to increase the strength and hardness of the steel plate by cold working methods such as rolling. The hard material uses a few percent to several tens of percent of the mild rolling to replace the mild flatness of the 2B base surface, and no annealing is carried out after rolling. Therefore, the TR hard surface of the hard material is the rolled after cold rolling surface.

- Rerolled Bright 2H: After the rolling process. the stainless steel strips will be processed bright annealing. The strip can be fast cooled by the the continuous annealing line. The traveling speed of the stainless steel strip on the line is around 60m~80m/min. After this step, the surface finish will be 2H rerolled bright.

- No.4: The surface of No. 4 is a fine polished surface finish that is brighter than the surface of No. 3. It is also obtained by polishing the stainless steel cold-rolled stainless steel plate with 2 D or 2 B surface as the base and polishing with abrasive belt with a grain size of 150-180# Machined surface. The surface roughness Ra value measured by the instrument is 0.2~1.5μm. NO.4 surface is widely used in restaurant and kitchen equipment, medical equipment, architectural decoration, containers, etc.

- HL: HL surface is commonly called hairline finish. Japanese JIS standard stipulates that 150-240# abrasive belt is used to polish the continuous hairline-like abrasive surface obtained. In China’s GB3280 standard, the regulations are rather vague. HL surface finish is mostly used for building decoration such as elevators, escalators, and facades.

- No.6: The surface of No. 6 is based on the surface of No. 4 and is further polished with a Tampico brush or abrasive material with a particle size of W63 specified by GB2477 standard. This surface has a good metallic luster and soft performance. The reflection is weak and does not reflect the image. Due to this good property, it is very suitable for making building curtain walls and building fringe decorations, and also widely used as kitchen utensils.

- BA: BA is the surface obtained by bright heat treatment after cold rolling. Bright heat treatment is annealing under a protective atmosphere that guarantees that the surface is not oxidized to preserve the gloss of the cold-rolled surface, and then use a high-precision smoothing roll for light leveling to improve the surface brightness. This surface is close to a mirror finish, and the surface roughness Ra value measured by the instrument is 0.05-0.1μm. BA surface has a wide range of uses and can be used as kitchen utensils, household appliances, medical equipment, auto parts and decorations.

- No.8: No.8 is a mirror-finished surface with the highest reflectivity without abrasive grains. The stainless steel deep processing industry also calls as 8K plates. Generally, BA materials are used as raw materials for mirror finishing only through grinding and polishing. After mirror finishing, the surface is artistic, so it is mostly used in building entrance decoration and interior decoration.

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Stainless Steel Strip Tensile Strength and Yield Strength

Stainless steel strip tensile strength can vary depending on the specific grade and condition of the material.

The tensile strength of stainless steel strip is typically measured in units of force per unit area, such as pounds per square inch (psi) or megapascals (MPa). The tensile strength indicates the maximum amount of tensile stress the material can withstand before breaking or deforming.

Different grades of stainless steel strips have different tensile strengths. Common stainless steel grades used for strip applications include AISI 301, 304, and 316L, among others. The tensile strength can range from around 75,000 psi (515 MPa) for lower-grade stainless steels to over 200,000 psi (1,380 MPa) for high-performance stainless steels.

It’s important to note that the tensile strength can also be influenced by factors such as the manufacturing process, heat treatment, and the thickness of the strip. Therefore, it’s crucial to consult the manufacturer’s specifications or relevant standards to determine the specific tensile strength of a particular stainless steel strip.

Stainless steel strip yield strength refers to the amount of stress or load that the material can withstand before it begins to deform permanently, or “yield,” without fracturing. Yield strength is an important mechanical property that helps determine the material’s suitability for specific applications.

The yield strength of stainless steel strip can vary depending on the grade and condition of the material, similar to tensile strength. It is typically measured in units of force per unit area, such as pounds per square inch (psi) or megapascals (MPa).

The yield strength is an essential consideration for design engineers as it helps determine the material’s ability to withstand applied loads without permanent deformation. It is often used in engineering calculations to determine the safety factor and design limits for various structural or load-bearing components.

Similar to tensile strength, the yield strength of stainless steel strip can be influenced by factors such as the grade, manufacturing process, heat treatment, and strip thickness. Therefore, it is important to refer to the manufacturer’s specifications or relevant standards to obtain the specific yield strength for a particular stainless steel strip grade.

Stainless Steel Precision Strip Hardness

Stainless steel precision strip hardness is one of the most important properties of a material and is used to characterize its resistance to plastic deformation. Hardness is defined as the resistance of a material to localized deformation, such as indentation, scratching, cutting or bending.

The hardness of stainless steel precision strip has a direct impact on its yield strength, tensile strength, elongation, deformation resistance, wear resistance and corrosion resistance.

In addition to the mechanical properties of stainless steel precision strip products, it is also one of the basic technical indexes for judging whether the product quality meets the requirements. Therefore, it is necessary to strictly control the hardness of stainless steel precision strip in production.

Stainless steel precision strip hardness is an important mechanical property of stainless steel precision strip, which is widely used in the manufacture of stainless steel strips.

The hardness of stainless steel precision strip can be expressed by the following two methods:

- Rockwell hardness (HRC)

- Vickers hardness (HV)

Stainless steel precision strip hardness shall be divided into soft, half-hard and hard types according to the different heat treatment processes. The main purpose is to distinguish the degree of cold processing after the raw material is delivered to the production line.

1. Soft: Commonly known as 1/4H or 2D, refers to the state after annealing or cold rolling with a large reduction ratio and no intermediate annealing.

2. Half hard: Commonly known as 1/2H or 2B, refers to the state after cold rolling with a small reduction ratio and no intermediate annealing.

3. Hard: Commonly known as 3/4H or 3B, refers to the state after heat treatment with high hardness, commonly known as hard state.

4. Full Hard: Commonly known as FH, and hardness will be from 430HV to 490HV.

5. Extra Hard: Commonly known as EH, and hardness will be from 490HV to 550HV.

6. Super Hard: Commonly known as SH, and hardness will be from 550HV to 650HV.

What Is Stainless Steel Strips Packaging?

Usually, the wooden case and wooden pallets are the two main types for stainless steel strips packaging. Eye to wall and eye to sky are both available.

- Firstly, waterproof paper is winding with bare stainless steel strips.

- Secondly, using plastic or steel banding strap to band stainless steel strips with wooden pallets together.

- Thirdly, using PVC film to package all stainless steel strips with pallets.

In addition, clear labels are tagged on the outside of these packages for easy identification of these strips measurements and quality information.

The fumigation wooden pallets and non-fumigation pallets are two kinds of wooden pallets types.

Because of the limit and customs requirements of various countries, so non-fumigation wooden pallets are widely used.

How To Choose Right Stainless Steel Strip For Your Project?

If you are the beginner of this area, you will be an expert through this guide.

The proportion of the nickel and chromium added is different, and the mechanical properties and application fields of the stainless steel strip produced are different.

It is mainly manifested in the following 12 aspects.

- Standard

- Grade

- Application

- Thickness

- Width

- Tolerance Of Thickness And Width

- Coil Inner Diameter

- Surface Treatment

- Edge

- Mechanical Properties

- Weight

- Packaging Type

What We Can Do For Your Stainless Steel Strips Project?

Our ability is supplying high quality stainless steel strips which allows us to provide our clients the strips material they need to create innovation products.

In case you have any question, feel free to contact HZW team. Here HZW will help you in all your stainless steel strips solutions.

From spring 301 stainless steel strip to super austenitic 654 SMO® stainless steel strip, here HZW will help you in all your stainless steel strips solutions.

Our staff at HZW is ready to consult with you on your specific demands when it comes to the manufacturing of stainless steel strips.

More Resources of Stainless Steel Strips

1.HZW BLOG

https://www.metalstripsolutions.com/blog/

2.Best 10 Stainless Steel Strips Manufacturers In India

Best 10 Stainless Steel Strips Manufacturers In India

3.Ulbrich Website

4.Stainless Steel Strip Manufacturers and Suppliers in the USA

https://www.thomasnet.com/products/stainless-steel-strip-80320005-1.html

5.Stainless Steel Strip Companies and Suppliers

https://www.iqsdirectory.com/stainless-steel-strip/